Bubble-assisted organic liquid film generator

A generator and bubble film technology, which is applied in the direction of liquid solution solvent extraction, etc., can solve the problems of uneven pressure distribution and unstable generation of gas phase and organic light phase, and achieve a compact device structure, convenient maintenance and management, and high integration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

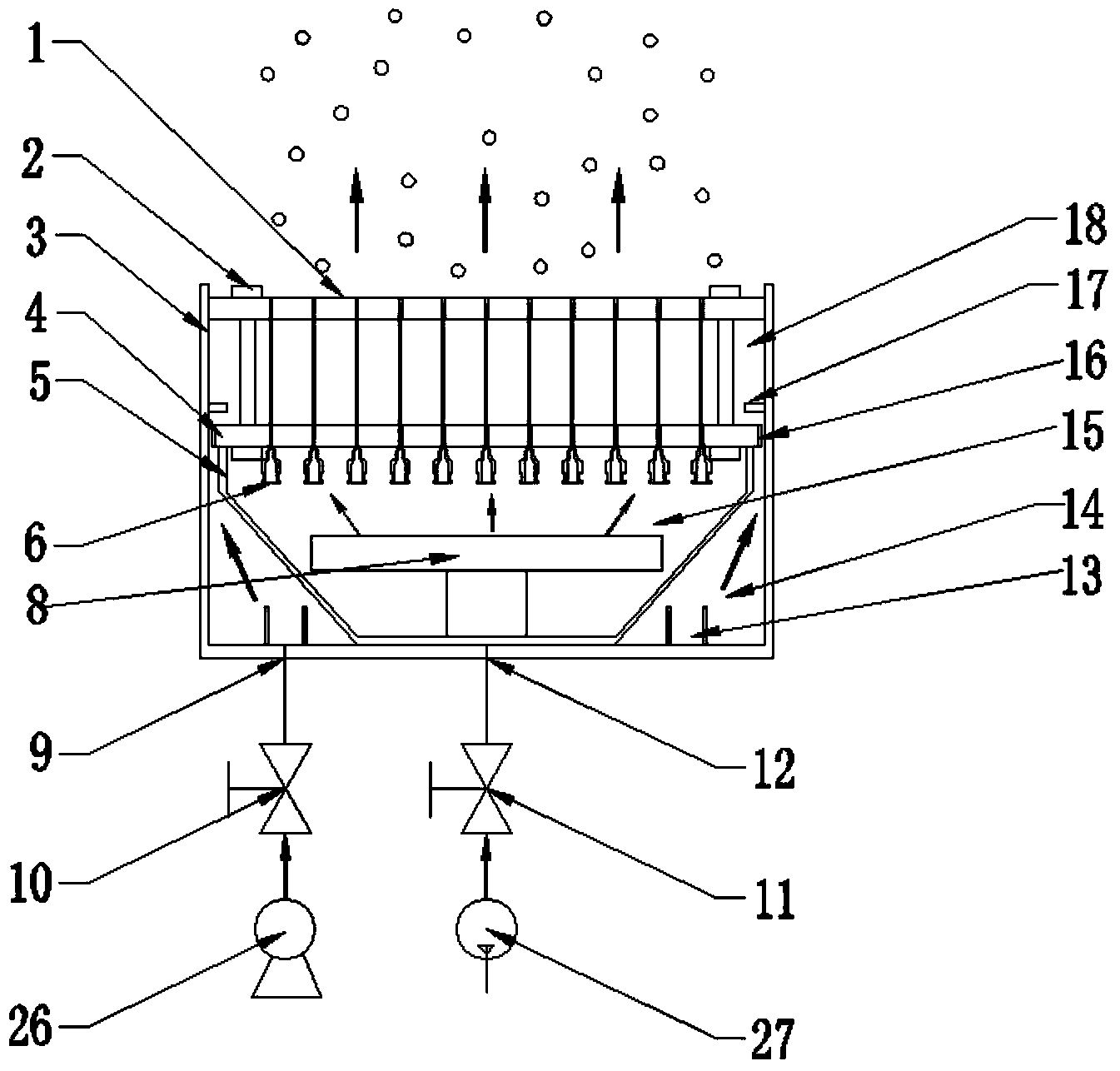

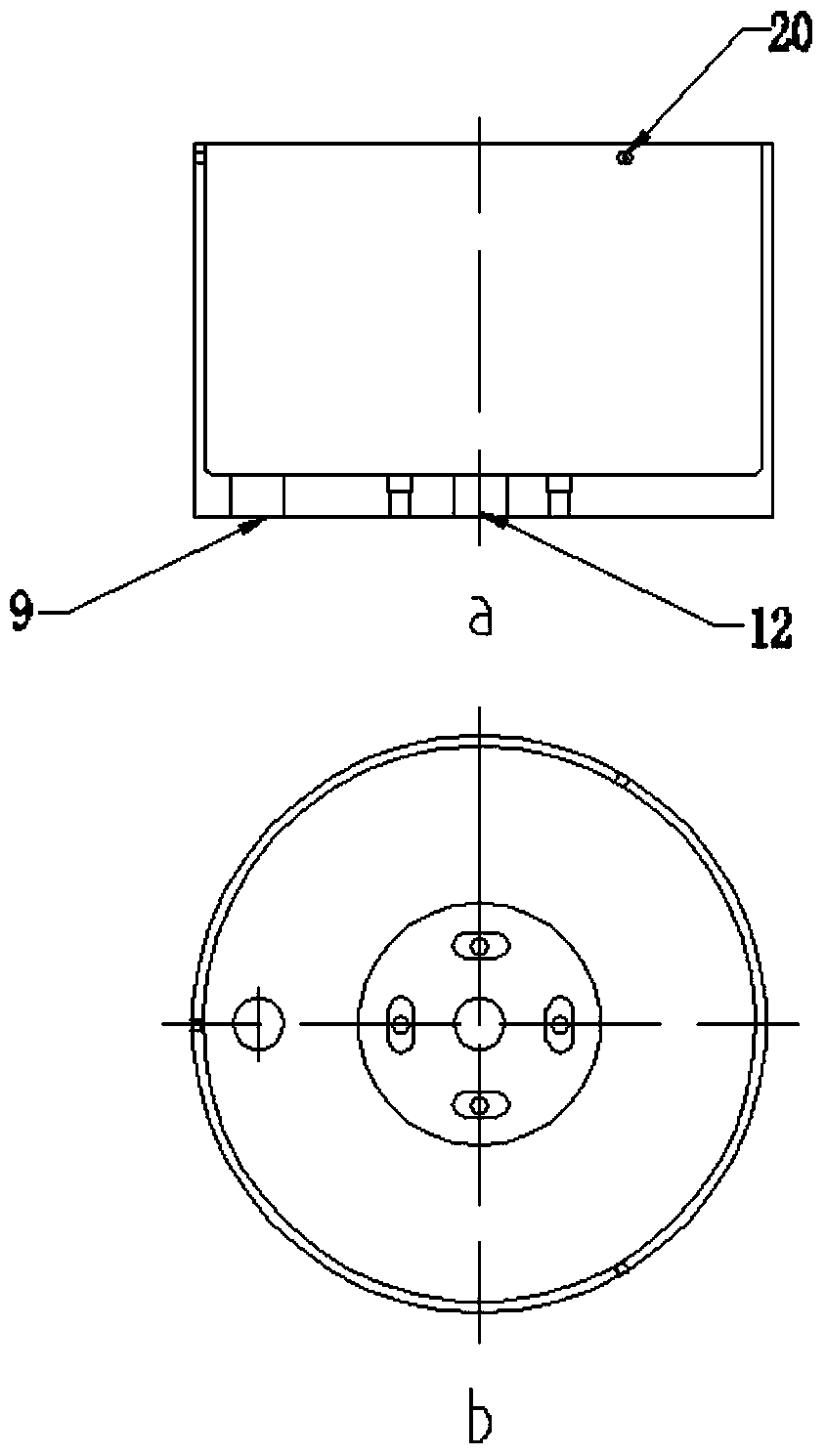

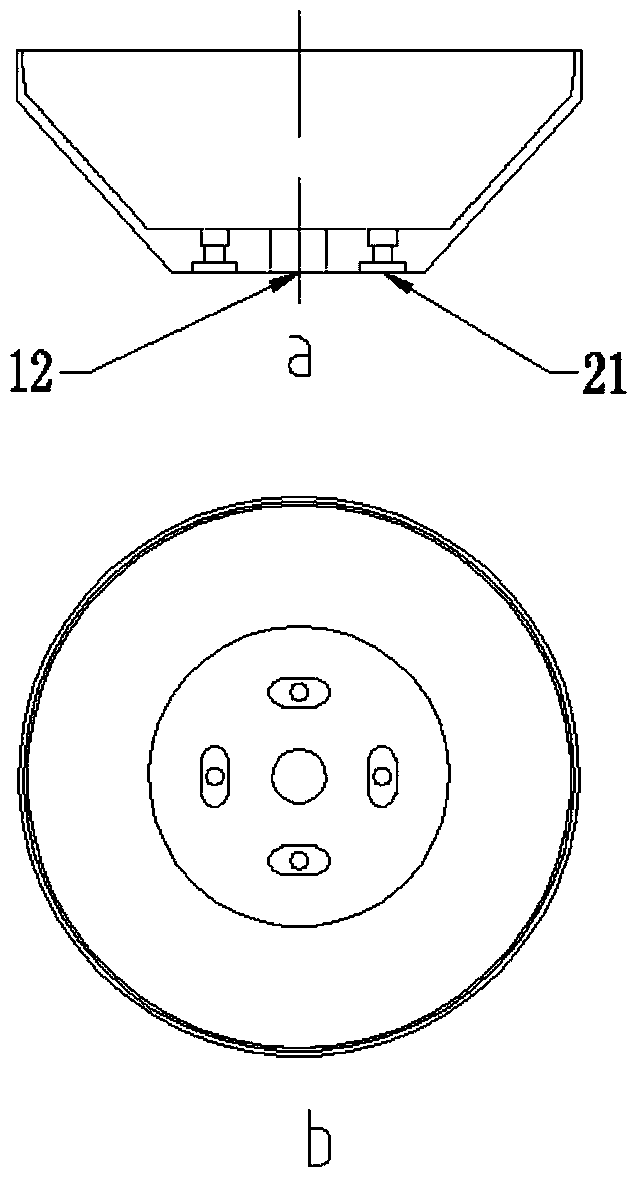

Embodiment 1

[0063] The bubble-assisted organic liquid film generator is used in an extraction tower with an inner diameter of 230 mm and an effective extraction height of 3 m for experimental verification. The organic light phase is a 1.54mol / L saponified P507-kerosene solution (volume ratio: P507: kerosene = 1:1), the water phase is a dilute solution with a La concentration of 100ppm and pH=2.5, and the feed rate of the organic light phase is 30L / h, the water phase is 100L / h, the gas phase pressure is 0.1MPa, and the specific load is 6. The inner diameter of the cavity of the generator shell is 210mm, the height is 125mm, the diameter of the bubble film generating hole is 0.4mm, the light phase distribution chamber is 40mm high, the light phase diversion hole and the surface of the air distribution plate are at a 45° oblique angle, and the internal diameter of the air distribution needle is 0.18mm, outer diameter 0.3mm, height 60mm, the distance between the air distributing needle and th...

Embodiment 2

[0065] The bubble-assisted organic liquid film generator is used in an extraction tower with an inner diameter of 230mm and an effective extraction height of 3m for experimental verification. The organic light phase is 1.54mol / L saponified P507-kerosene solution (volume ratio: P507: Kerosene=1:1), the water phase is a dilute solution with a La concentration of 100ppm and pH=2.5, the feed rate of the organic light phase is 30L / h, the water phase is 100L / h, the gas phase pressure is 0.1MPa, and the specific load is 6 . The inner diameter of the cavity of the generator shell is 210mm, the height is 125mm, the diameter of the bubble film generation hole is 0.8mm, the light phase distribution chamber is 40mm high, the light phase diversion hole and the surface of the air distribution plate are at a 45° oblique angle, and the internal diameter of the air distribution needle is 0.6mm, outer diameter 0.7mm, height 60mm, the distance between the air distributing needle and the surface o...

Embodiment 3

[0067] The bubble-assisted organic liquid film generator is used in an extraction tower with an inner diameter of 230mm and an effective extraction height of 3m for experimental verification. The organic light phase is 1.54mol / L saponified P507-kerosene solution (volume ratio: P507: Kerosene=1:1), the water phase is a dilute solution with a La concentration of 100ppm and pH=2.5, the feed rate of the organic light phase is 30L / h, the water phase is 100L / h, the gas phase pressure is 0.1MPa, and the specific load is 6 . The inner diameter of the cavity of the generator housing is 210mm, the height is 145mm, the diameter of the bubble film generation hole is 3.0mm, the light phase distribution chamber is 60mm high, the light phase diversion hole and the surface of the air distribution plate are at a 45° oblique angle, and the internal diameter of the air distribution needle is 2.6mm, outer diameter 2.9mm, height 60mm, the distance between the air distributing needle and the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com