Gold jewelry and processing method thereof

A processing method and jewelry technology, which is applied in the field of gold jewelry, can solve the problems of affecting wearing and use, large loss, and difficulty in returning to the original, etc., and achieve the effect of improving the yield rate, high compressive strength, and uniform cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

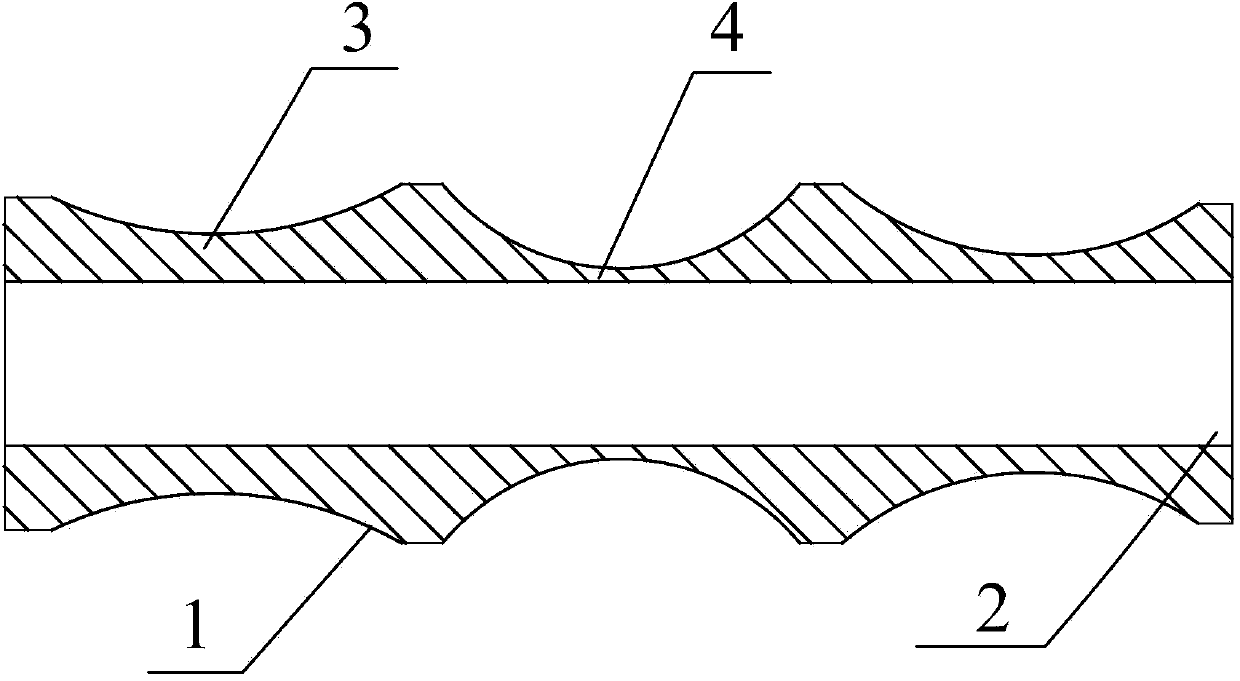

[0028] A gold jewellery, comprising a cylindrical part, the cylindrical part includes a cylindrical wall, and the feature is that the thickness of the cylindrical wall at each part of the cylindrical part is equal.

[0029] Since the wall thickness of the cylindrical part is equal on each cross-section of the cylindrical part, this structure of equal wall thickness avoids the situation of thin-walled parts and thick-walled parts of the cylindrical part, thus avoiding the When the shape part bears the same pressure, the stress concentrates on the part with thinner wall thickness. When the cylindrical part is under pressure, the pressure on each wall is the same, and the external pressure is evenly shared, avoiding the breaking of the cylindrical part due to excessive pressure at one place, and the uniformity of the cylindrical part Under pressure, the compressive strength of the cylindrical part is greatly improved, which is convenient for the assembly, wearing and use of jewel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com