Intelligent sampling method and application of method in cigarette quality control

An intelligent and high-quality technology, applied in applications, tobacco, cigarette manufacturing, etc., can solve problems such as excessive sampling frequency setting, product quality and equipment impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0053] The implementation mode introduces an application of the intelligent sampling method in the field of cigarette production. In fact, the intelligent sampling method of the present invention is not limited to this field, and can also be applied to the automatic detection of other products.

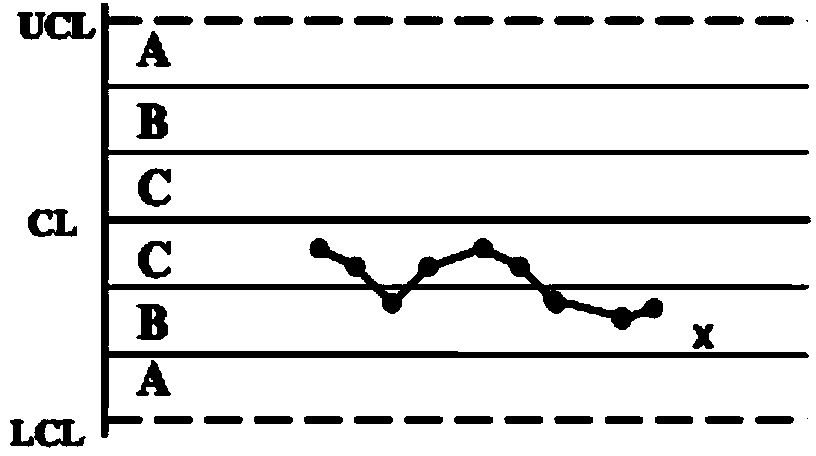

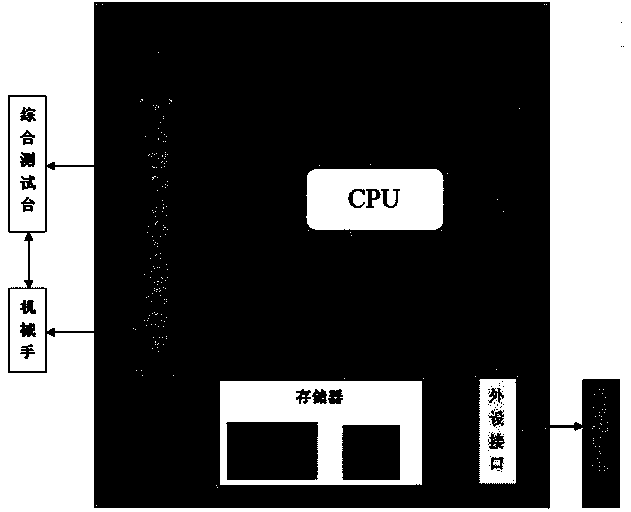

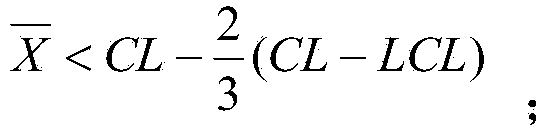

[0054] Such as figure 1 As shown, the working principle of the hardware involved in the method of the embodiment and the intelligent controller of the sampling system is as follows: after the intelligent controller of the sampling system is powered on, it first obtains its sampling state from the manipulator, and sends a sampling instruction when the state of the manipulator is idle. Including the collection time and the number of collections, the manipulator starts to collect cigarettes to the comprehensive test bench after receiving instructions, and the comprehens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com