Drillship having block for preventing vortex with concave type flow stabilizer part in moonpool

A technology for stabilizing parts and drilling ships, applied in the direction of hydrodynamic characteristics/hydrostatic characteristics, hull, hull parts, etc., can solve the problems of reducing pressure variability, not reducing external flow, increasing the weight of drilling ships, etc., to achieve improvement Effects of resistance performance, improved economy, and high expectation of use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, the structures and functions of the embodiments of the present invention will be described in detail in conjunction with the accompanying drawings, as follows. In describing the embodiments of the present invention, if the relevant known functions or specific descriptions about its structure are considered to interfere with the gist of the present invention, the detailed description will be omitted.

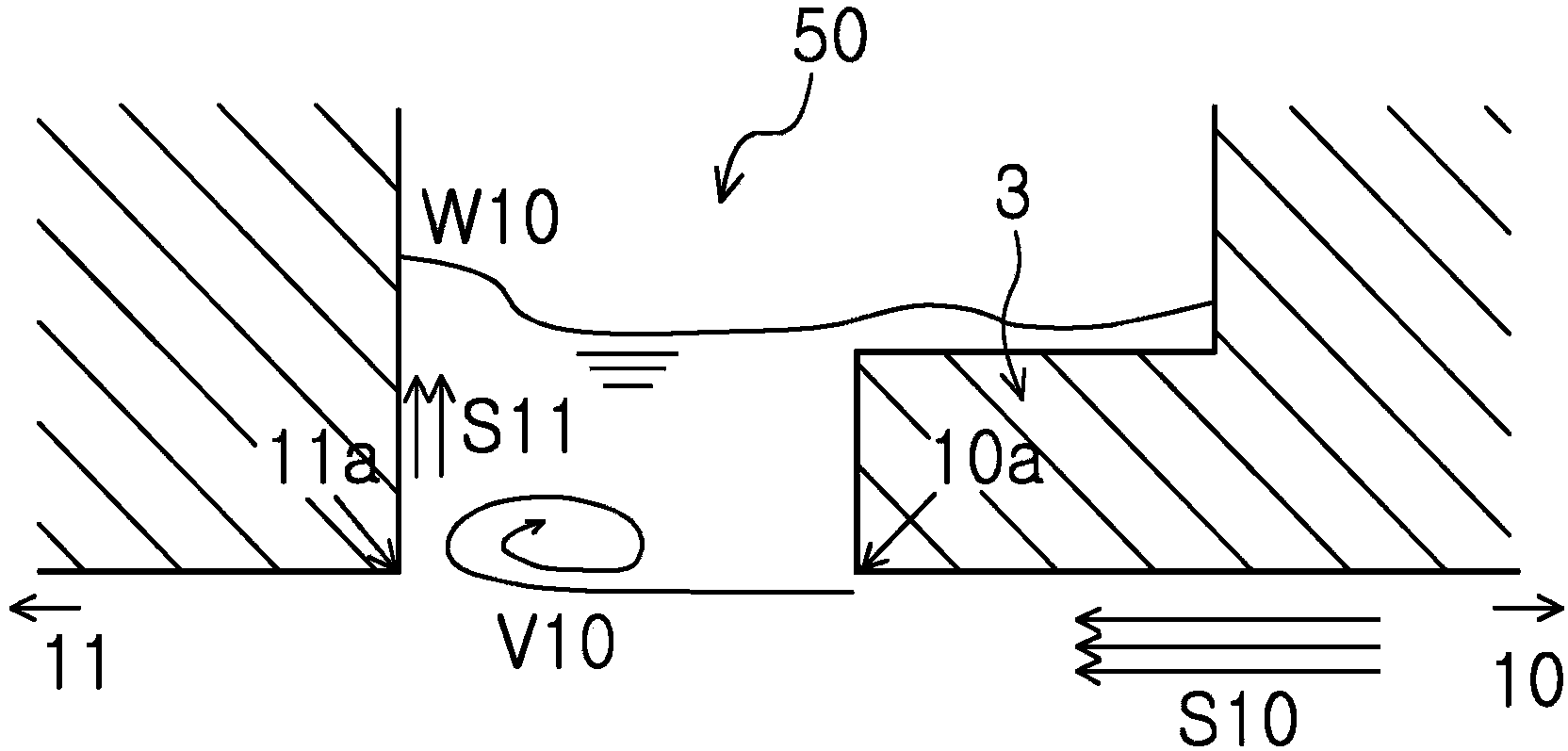

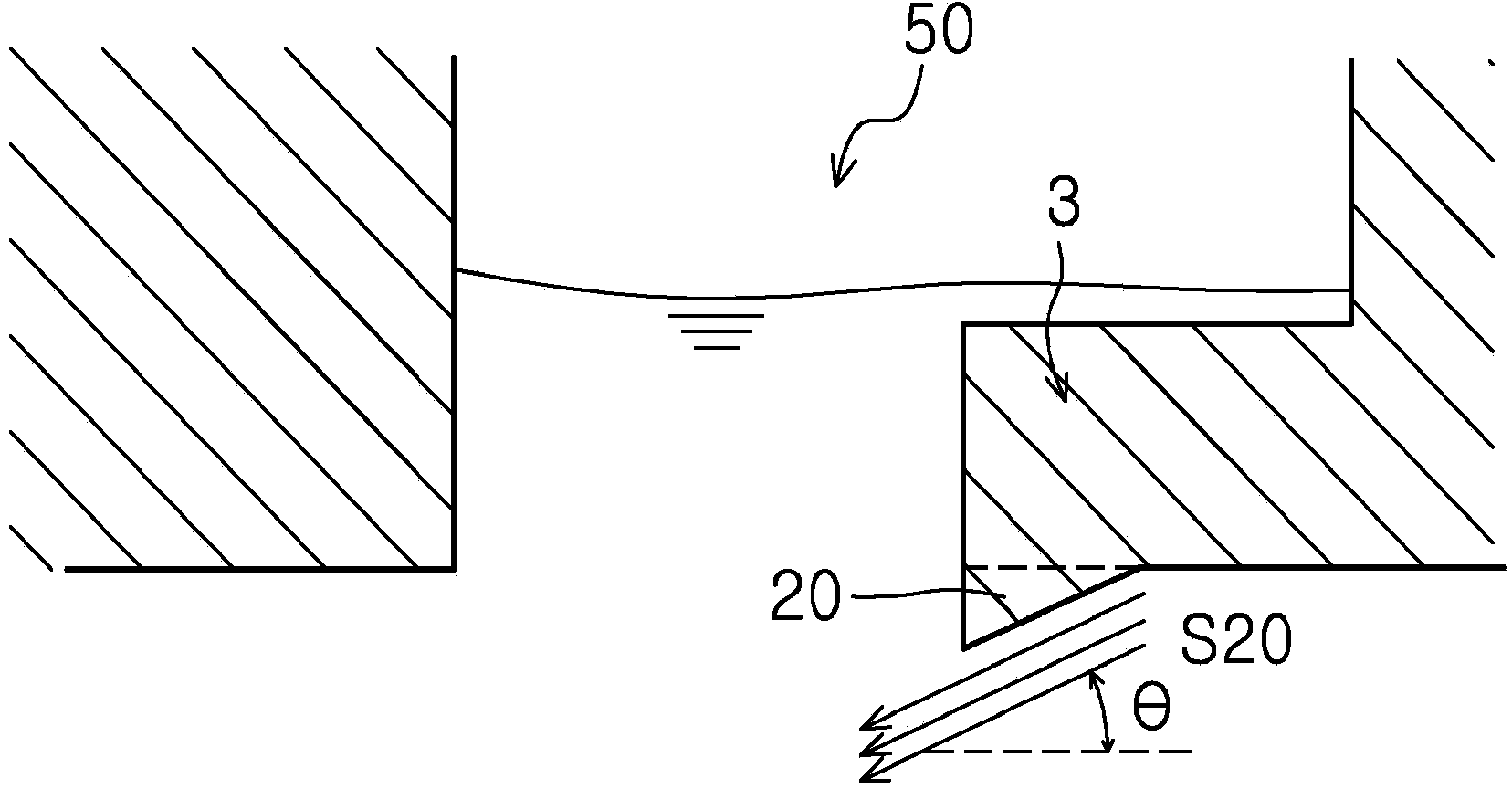

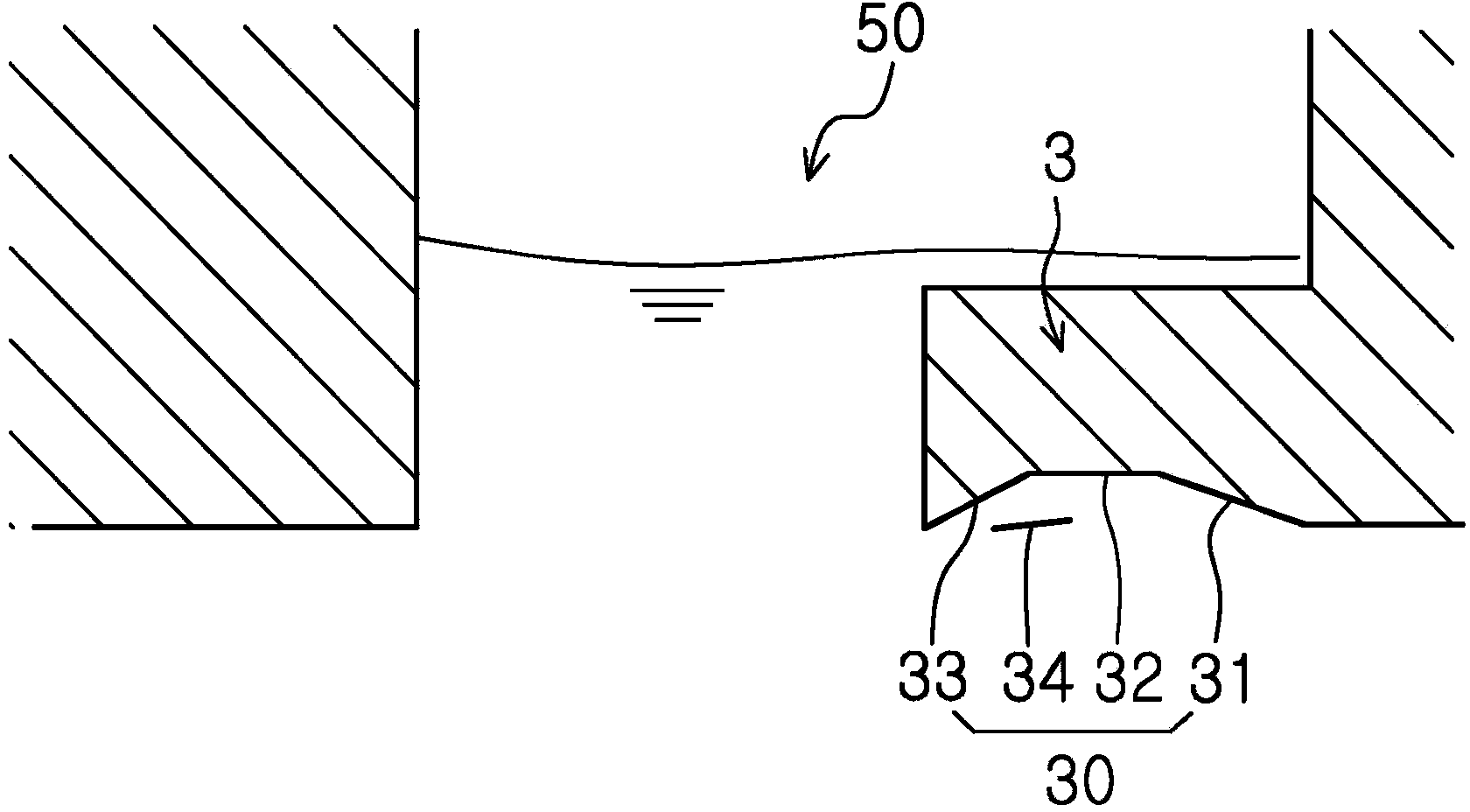

[0057] image 3 It is a side view of a boat well with a flow stabilizing part according to an embodiment of the present invention. As shown in the figure, the present invention constitutes a concave flow stabilizing part 30, which will be used to suppress the vortex generated by the external flow S10 in order to suppress The lower bottom of the block 3 of the eddy current is formed by being recessed toward the upper part of the hull, and the external flow flows into the ship well 50 vertically installed on the hull of the drilling ship. The bottom of the ship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com