Power supply system for variable-frequency winch

A technology of power supply system and winch, applied in the control system, electrical components, AC motor control and other directions, can solve the problem that the protection device cannot fully absorb, burn out the circuit board of the low-power motor, and it is too late to make protection actions, and achieves the benefits of Routine maintenance, reducing failure points and hidden danger points of explosion, and the effect of stable power supply for the main motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

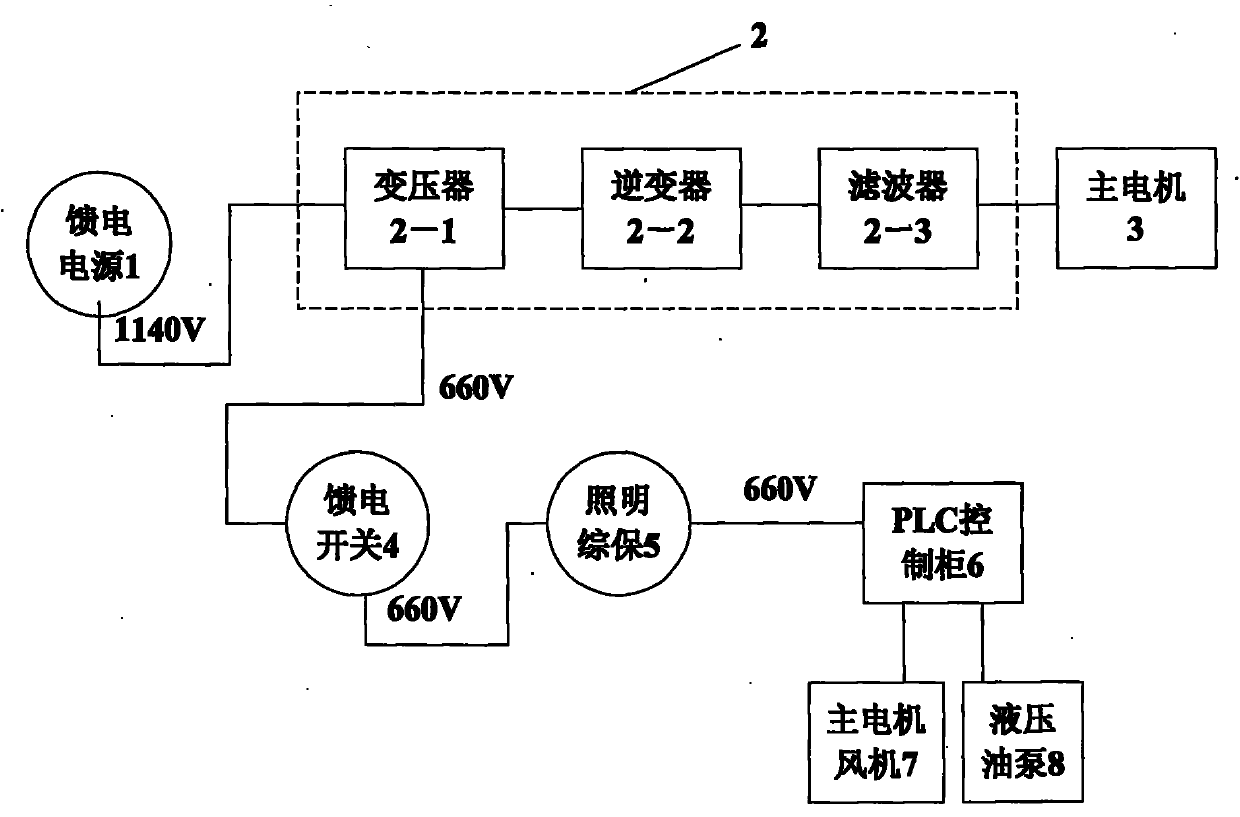

[0014] As shown in Figure 1, a power supply system of a frequency conversion winch includes a feed power supply 1, a main motor 3, a frequency converter 2, a main motor fan 7, and a hydraulic oil pump 8 for the frequency conversion winch, and the feed power supply 1 and frequency conversion The inverter 2 is connected to supply power for it, and the output terminal of the frequency converter 2 is connected to the main motor 3; the frequency converter 2 includes a transformer 2-1 for converting the power supply voltage, a filter 2-3 for eliminating interference and enhancing its electromagnetic compatibility, and an inverter 2-2 for reducing power; the output terminal of the transformer 2-1 is connected to the input terminal of the lighting comprehensive protection 5, and the transformer 2-1 steps down the voltage of the 1140V feed power supply 1 to a 660V low voltage For the lighting comprehensive protection 5 to work, the output end of the lighting comprehensive protection 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com