Polygonal mirror cavity structure and manufacturing method thereof

A manufacturing method and polygonal technology, applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as mirror breakage, stress generation, and mirror deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] In order to enable your review committee members to have a further understanding and understanding of the characteristics of the present invention and the achieved effects, I would like to provide preferred embodiments and detailed descriptions, as follows:

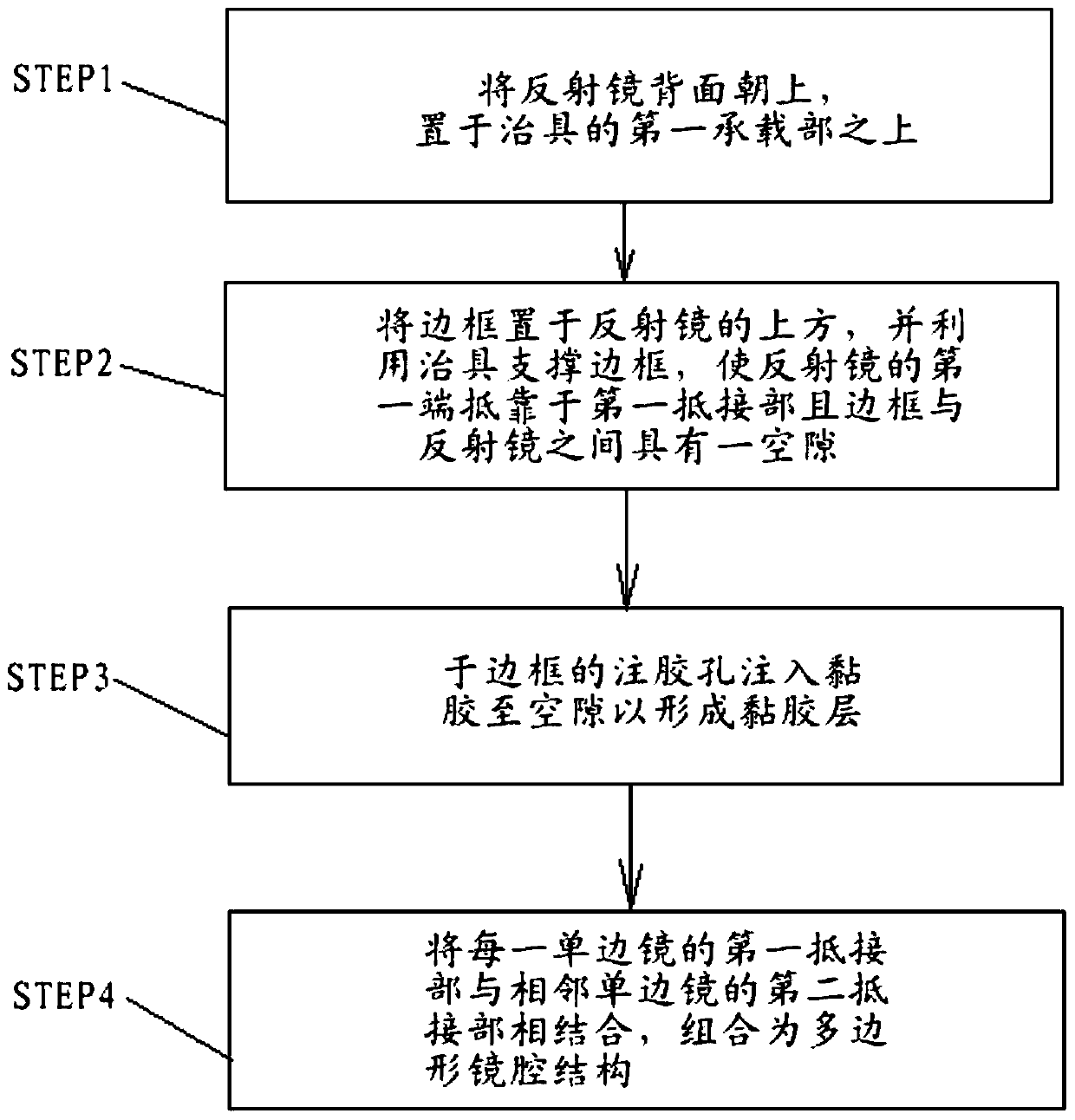

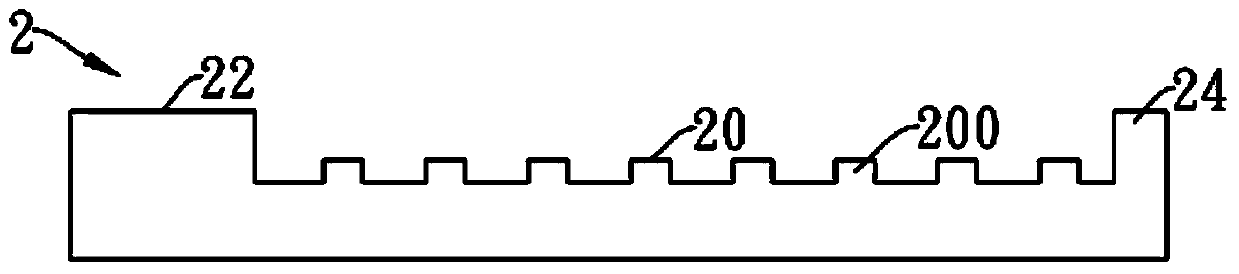

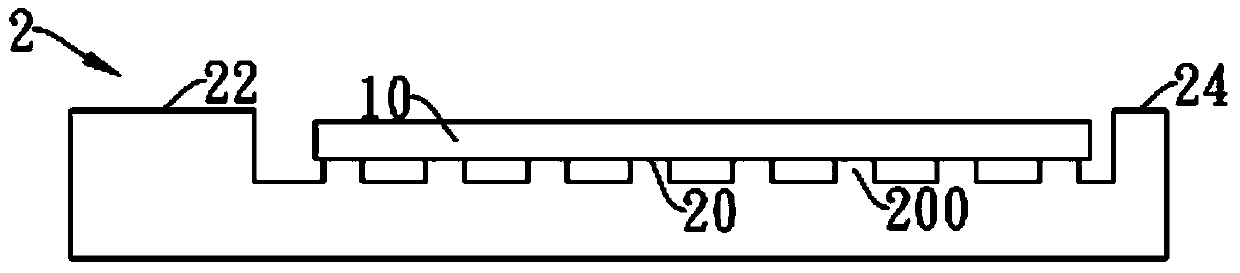

[0084] The invention proposes a polygonal mirror cavity structure and its manufacturing method, which is characterized in that: each single-sided mirror can adjust the thickness of the adhesive layer to offset the influence of the thickness tolerance caused by the production of the mirror, and maintain the single-sided mirror. The overall thickness keeps an appropriate gap between two adjacent mirrors to avoid light leakage or collision damage. In addition, one end of each single-sided mirror can form an accommodating space to accommodate the other end of the adjacent single-sided mirror. The space can buffer the length tolerance caused by the manufacture of the reflector, so that the length tolerance will not affec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com