Measuring method of mesoscopic structure change law in soil stretching process

A technology of mesoscopic structure and changing rules, applied in the direction of applying stable tension/pressure to test the strength of materials, so as to avoid the concentration of tensile stress and accurately measure the effect of tensile strength of soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: The method for testing the meso-structure change law of the soil in the stretching process of the present invention includes the following steps:

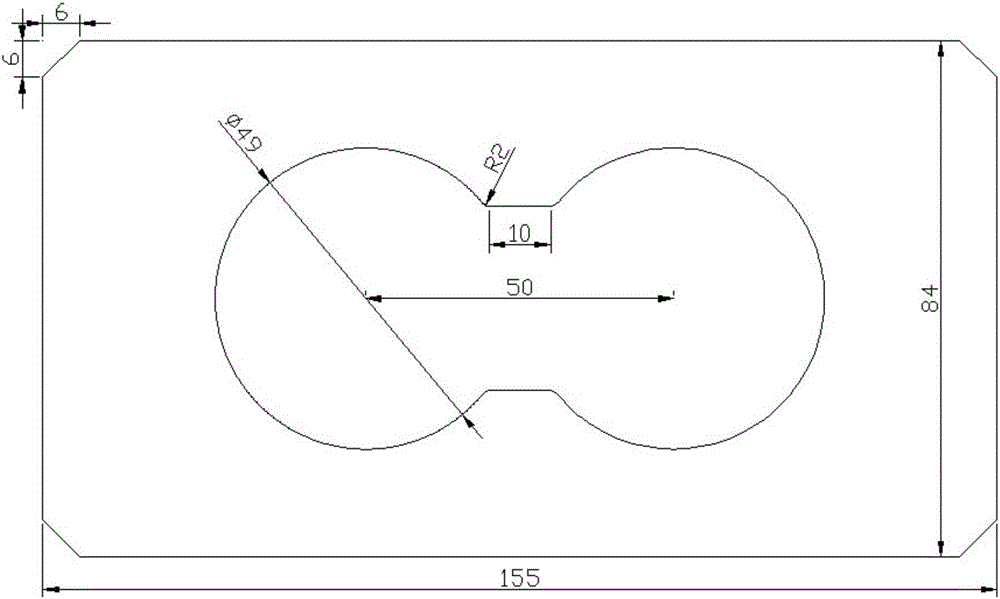

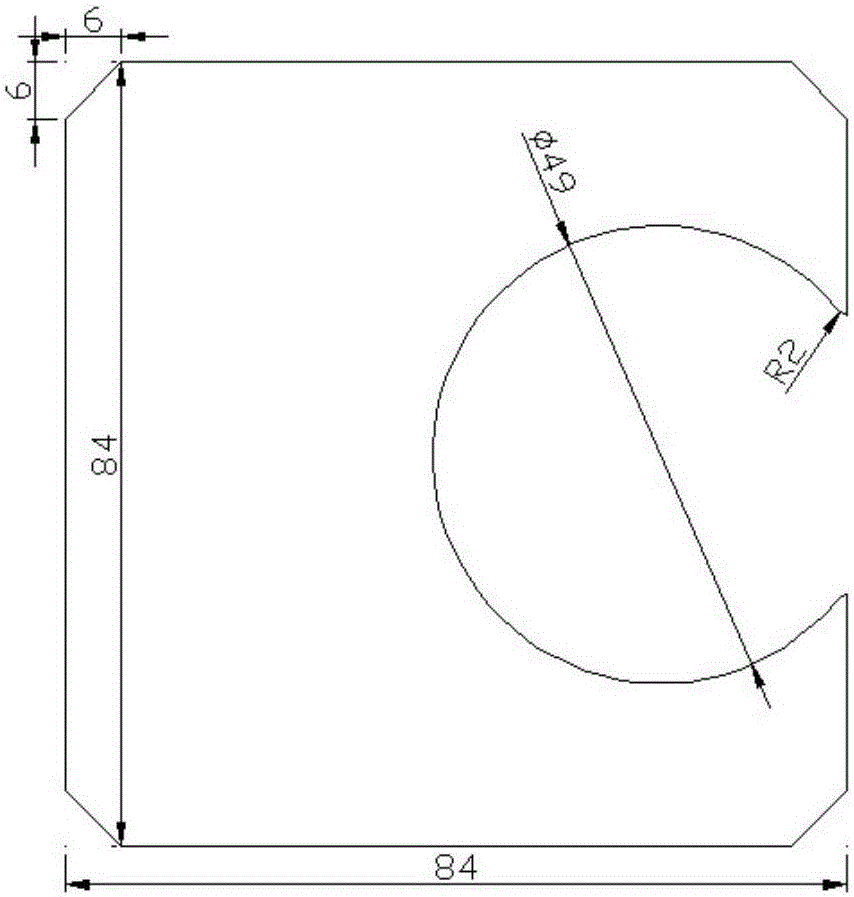

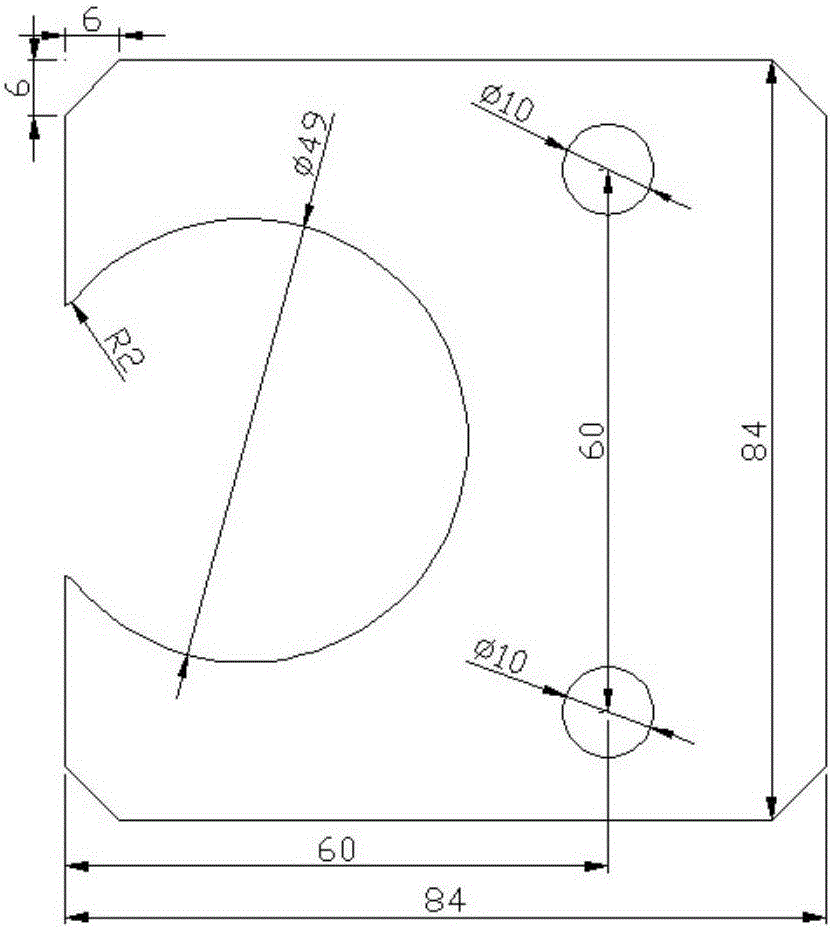

[0037] (1) Making soil sample: Weigh the soil sample according to the dry density, and after the soil is mixed and cured, it is compacted in 5 layers in a mold. The shape of the prepared soil sample is similar to a dumbbell, and the two ends are cylindrical clamping ends. , The middle is a cubic stretch section, with a smooth transition between the two clamping ends and the stretch section (the radius of curvature is 2mm), the sample height is 40mm, and the center of gravity of the two clamping ends and the stretch section is on the same horizontal line . The floor plan of the mold is as figure 1 Shown. Maximum dry density obtained according to compaction test γ max =1.75g / cm 3 , The compaction of the sample is 95%, and the volume of the sample is 153.6cm 3 , The initial water content is 12%, and the calculated ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compactness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com