A waste gas treatment equipment for nitriding furnace

A technology of waste gas treatment equipment and nitriding furnace, which is applied in the direction of incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of waste gas treatment residues in nitriding furnaces, and achieve the effect of avoiding residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

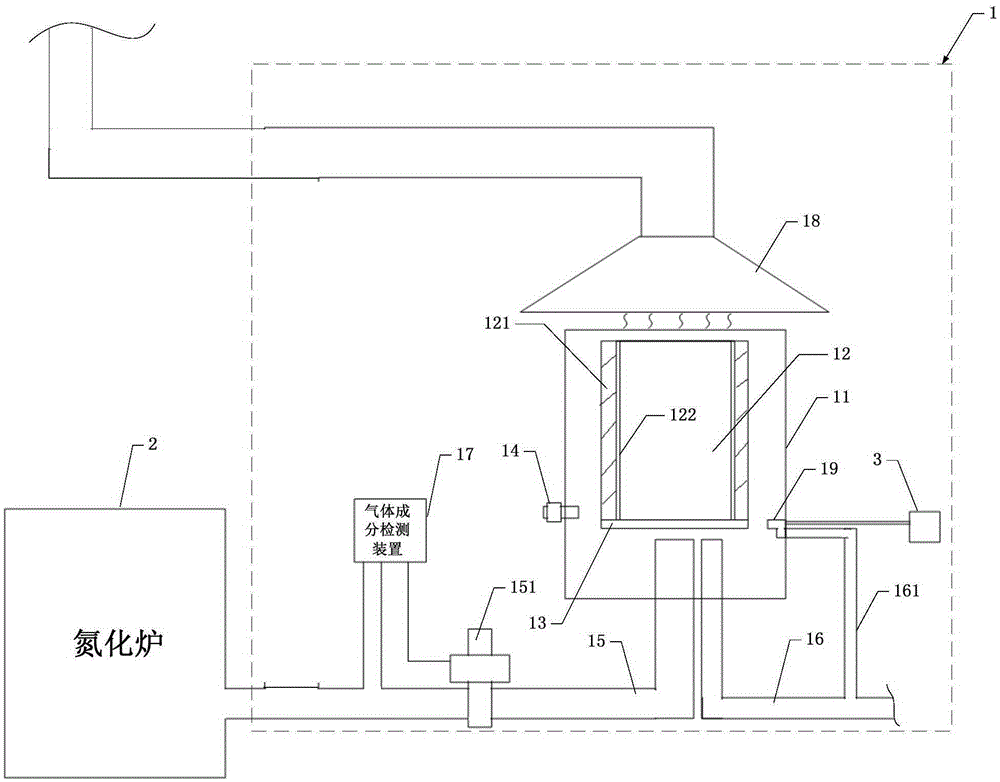

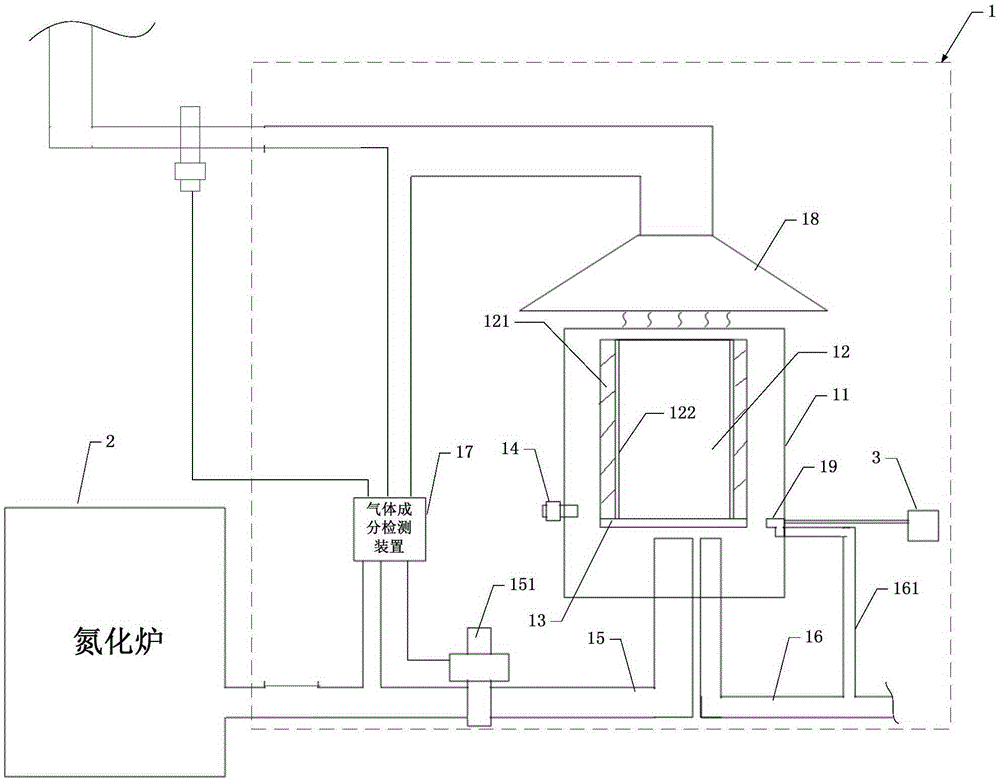

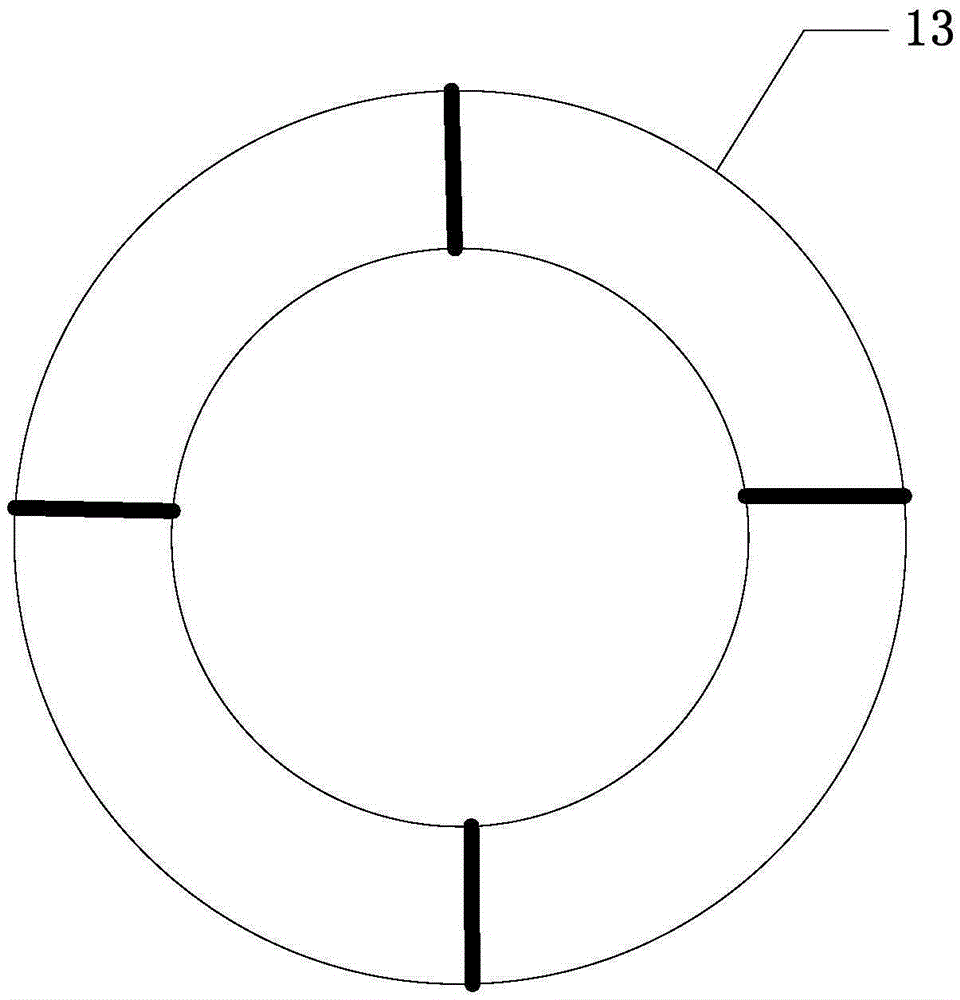

[0035] Such as figure 1 As shown, the present invention provides a waste gas treatment equipment 1 for nitriding furnaces, including: a device body 11 with an open upper end, and a combustion chamber 12 that penetrates up and down inside, and the bottom of the combustion chamber 12 is hollowed out or has ventilation The metal ring 13 of the hole, the metal ring 13 can be fixed by snapping or welding, and the device body 11 is also provided with: through the exhaust gas or closing the exhaust gas, the combustion chamber 12 can maintain the pressure required for the combustion of the exhaust gas. Pressure valve 14; exhaust gas transmission pipeline 15, connected to the nitriding furnace 2, and the gas outlet of the exhaust gas transmission pipeline 15 is sent from the bottom of the device body 11 to the combustion chamber 12, and is located under the metal ring 13 The gas outlet of the gas pipeline 16 communicates with the combustion chamber 12 from the bottom of the device body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com