Method for determining distance between block valve chambers of long-distance natural gas pipeline

A technology for long-distance pipelines and determination methods, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

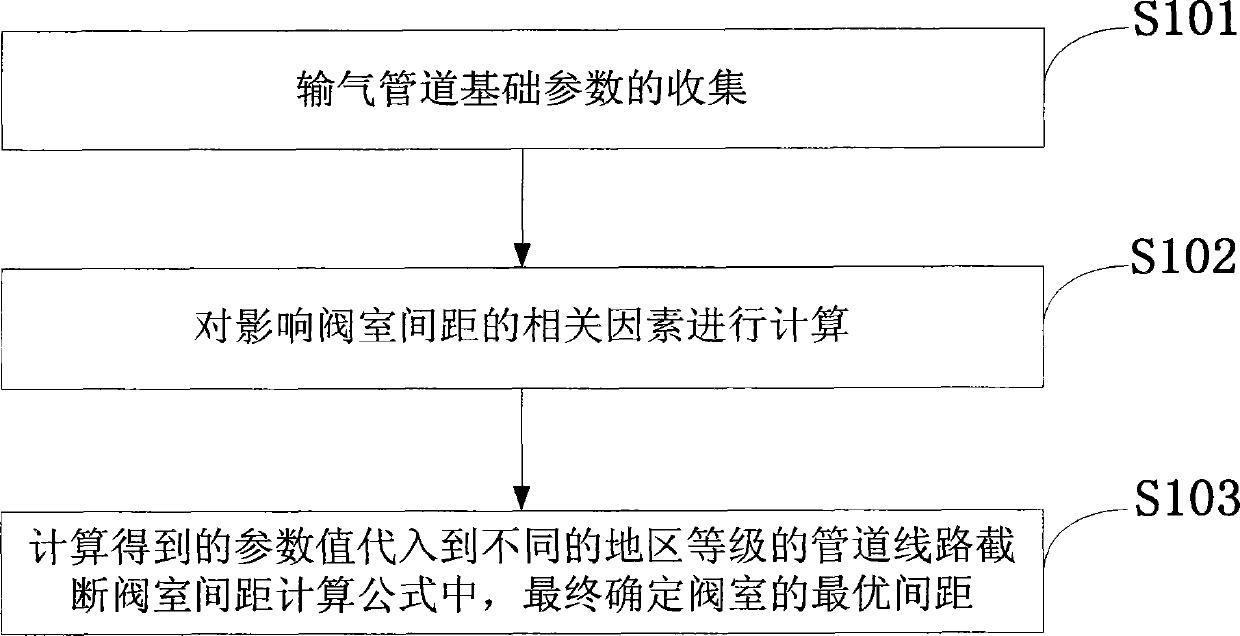

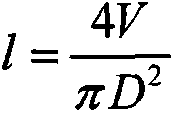

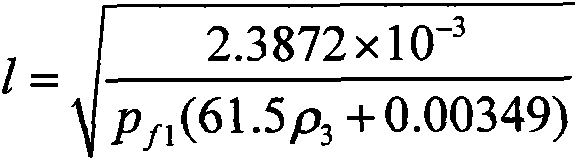

Method used

Image

Examples

Embodiment 1

[0162] Embodiment 1. According to the U.S. regional grading standard, determine the distance between line cut-off valve chambers of pipelines in grades 1, 2, 3 and 4, and compare with the ASME B31.8 standard to verify the accuracy of the present invention.

[0163] Table 5 Failure frequency of long-distance natural gas pipelines in the United States

[0164]

[0165] Table 6 Population Density of Regions of Different Levels in the United States

[0166] Level 1 area 1~10 households secondary area 11~45 households Tertiary area 46~100 households Level 4 area >=101 households

[0167] Note: In Table 6, the population of each household is 3 persons.

[0168] Table 7 Comparison between the calculated value and the standard value of valve chamber spacing in different grades of the United States (km)

[0169]

[0170]

[0171] According to the calculation results, it can be seen that the distance between the valve chambers calculated a...

Embodiment 2

[0172] Embodiment 2. In this example, the distance between the pipeline line cut-off valve chambers in the first-level and second-level areas is determined according to the regional classification standards of our country.

[0173] Table 8 Population Density of Regions of Different Levels in China

[0174] Level 1 area 1~15 households secondary area 16~99 households

[0175] Tertiary area 100-200 households Level 4 area >=201 households

[0176] Note: In Table 8, the population of each household is 3.1 persons

[0177] Table 9 Failure frequency and correction coefficient of natural gas pipelines damaged by third parties

[0178] District level Level 1 and Level 2 areas Frequency of failure due to third-party damage related to pipe diameter 0.135 Wall Thickness Correction Factor 1

[0179] position correction factor 1 Buried depth correction factor 1 Correction factor for protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com