Valve core component of automatic control valve

A technology for automatic control of valve and valve core components, applied in engine components, lift valves, valve details, etc., can solve the problems of resource waste, leakage, unreliable work, etc., and achieve the effect of not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

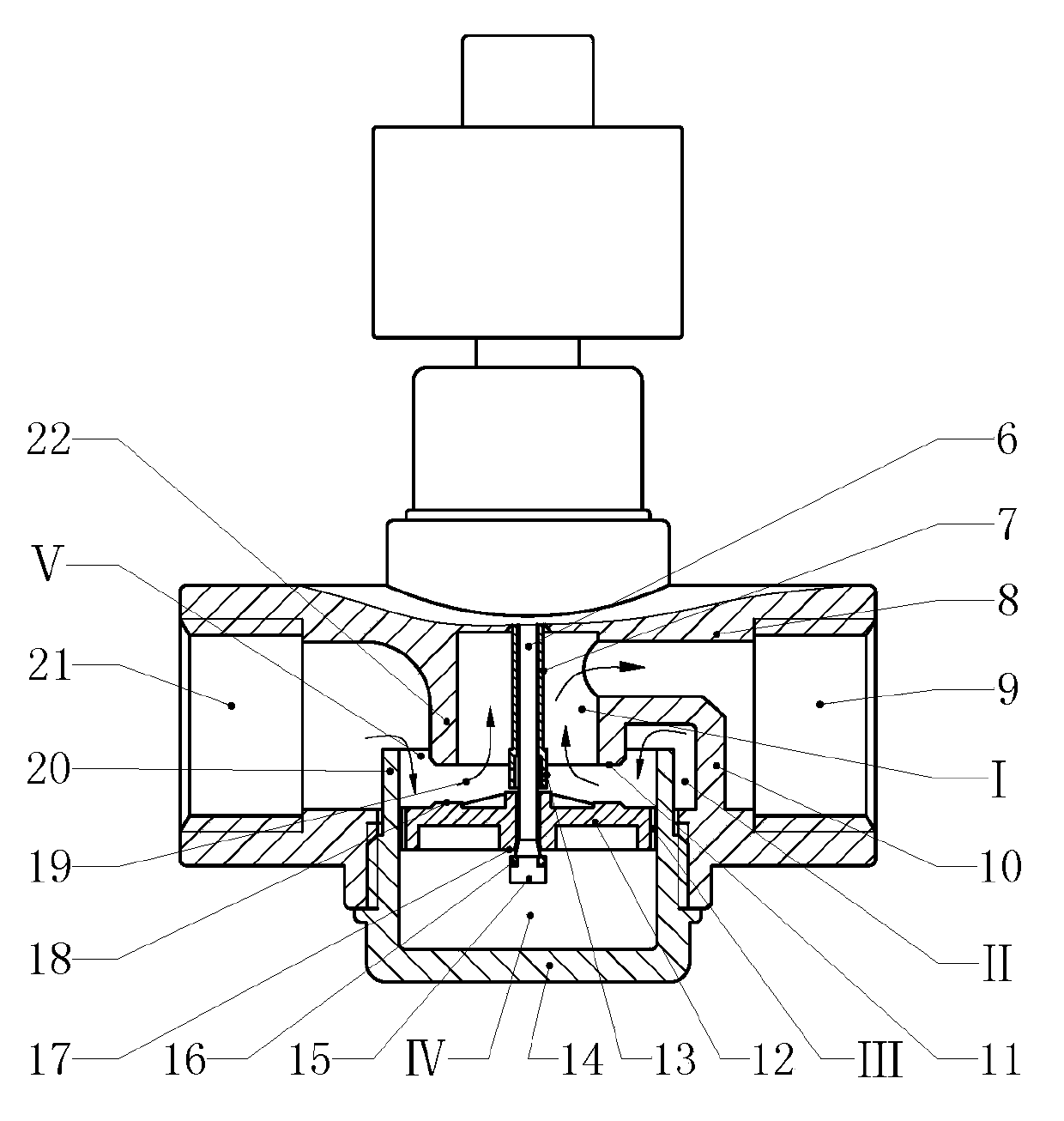

[0014] Embodiment 1 Attached figure 1In the shown embodiment, the spool assembly of the automatic control valve consists of a valve seat (22), a ring wall (20), a valve plate (12), a connecting rod (6) and a bottom cover (14), wherein the valve seat (22) is set in the inner cavity of the valve body (8), the valve seat (22) is a rotary structure, the upper end of the valve seat (22) is connected with the valve body (8), and the lower port of the valve seat (22) Constitute the sealing surface (11), the inner space of the valve seat (22) constitutes the upper valve chamber (I), and the upper valve chamber (I) is connected to the fluid output port (9) of the valve body (8); the ring wall (20) is set Below the valve seat (22), the upper port of the ring wall (20) surrounds the lower periphery of the valve seat (22), the lower end of the ring wall (20) is connected to the bottom cover (14), and the ring wall (20) and There is a space between the valve seats (22), the space between ...

Embodiment 2

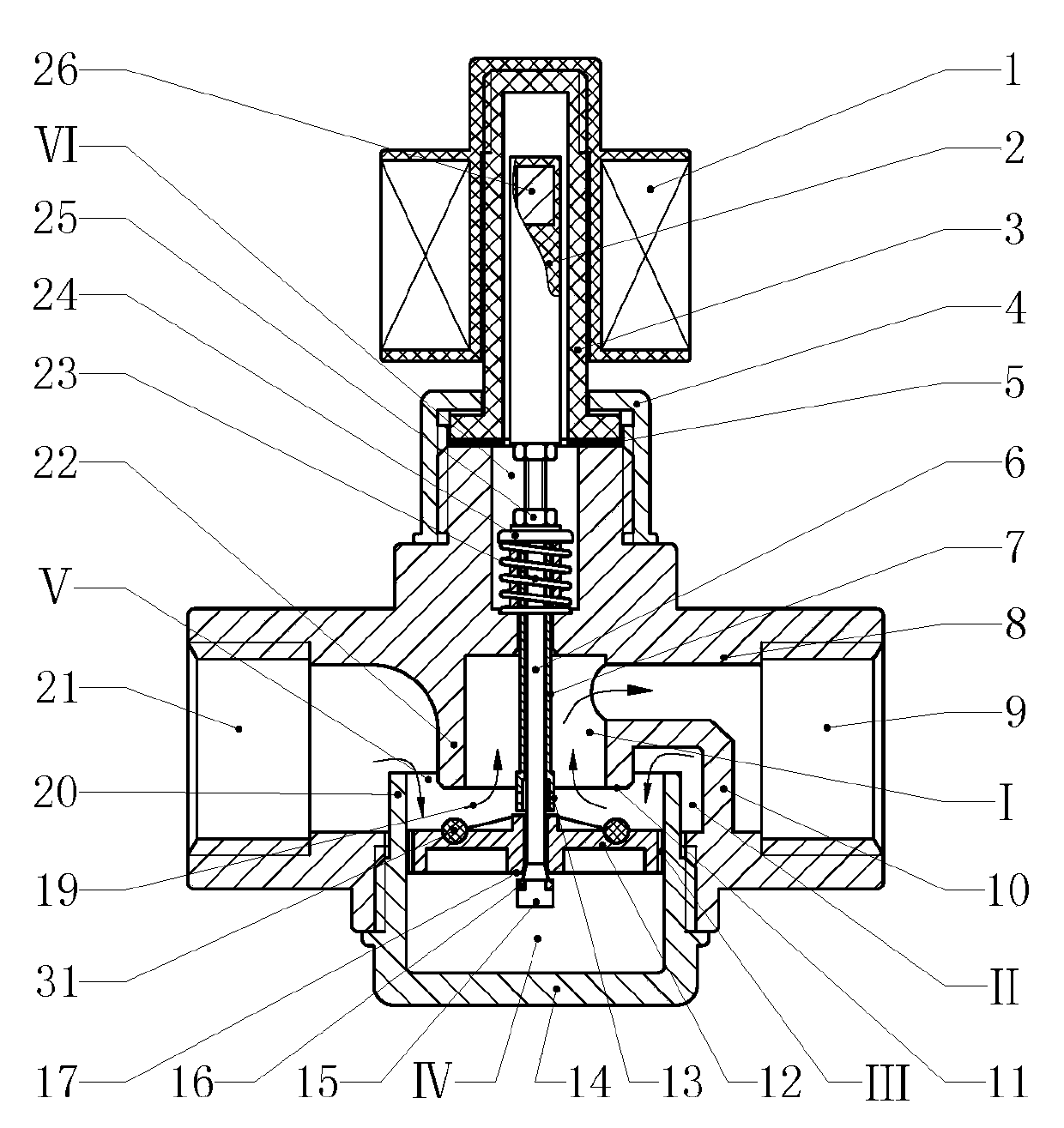

[0015] Embodiment 2 Attached figure 2 In the shown embodiment, the electromagnetic valve composed of the valve core assembly of the present invention mainly consists of a valve seat (22), a ring wall (20), a valve plate (12), a connecting rod (6), a bottom cover (14), an electromagnetic Coil (1), guide rod (2), magnetic sleeve (3), magnet (26) and spring (23), wherein, the valve seat (22) is set in the inner cavity of the valve body (8), the valve The seat (22) is a revolving body structure, the upper end of the valve seat (22) is connected with the valve body (8), the lower port of the valve seat (22) forms the sealing surface (11), and the inner space of the valve seat (22) forms The upper valve cavity (I), the upper valve cavity (I) is connected to the fluid output port (9) of the valve body (8); the ring wall (20) is set under the valve seat (22), and the upper The port surrounds the lower periphery of the valve seat (22), the lower end of the ring wall (20) is connected...

Embodiment 3

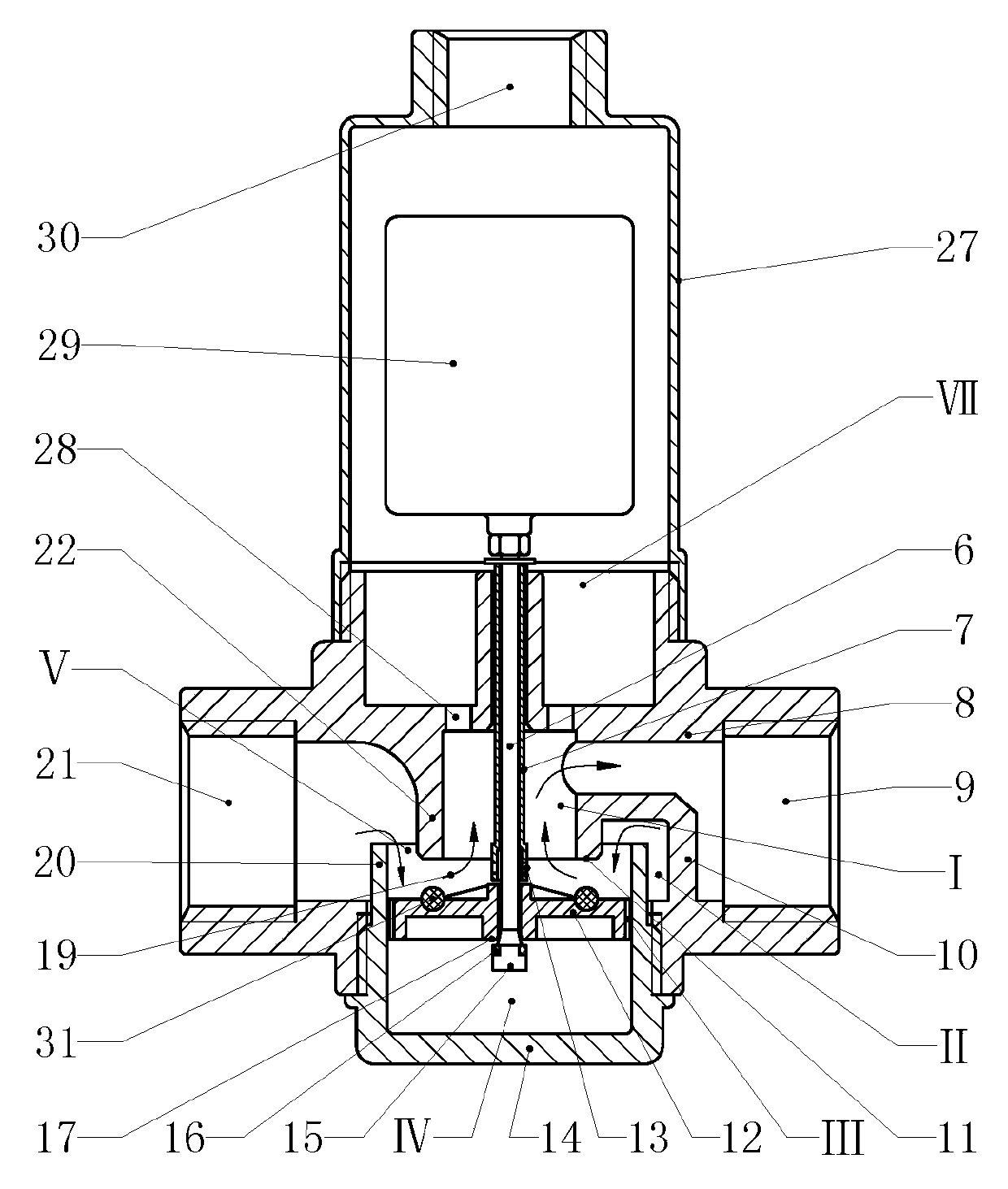

[0016] Example 3 Attached image 3 In the embodiment shown, an automatic liquid level control valve composed of the valve core assembly of the present invention mainly consists of a valve seat (22), a ring wall (20), a valve plate (12), a connecting rod (6), a bottom cover (14), the float (29) and the wall (27) of the water chamber, wherein the valve seat (22) is set in the inner cavity of the valve body (8), the valve seat (22) is a rotary structure, and the valve seat The upper end of (22) is integrated with the valve body (8), the lower port of the valve seat (22) constitutes the sealing surface (11), the inner space of the valve seat (22) constitutes the upper valve chamber (I), and the upper valve chamber ( Ⅰ) Connected to the fluid output port (9) of the valve body (8); the ring wall (20) is set under the valve seat (22), and the upper port of the ring wall (20) surrounds the lower periphery of the valve seat (22) , the lower end of the ring wall (20) is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com