Ceramic plate curtain wall mounting structure and ceramic plate curtain wall mounting method

A technology of installation structure and installation method, applied in the direction of walls, building components, building structures, etc., can solve the problems of easily broken ceramic panels, reduced strength of ceramic panels, affecting the progress of construction, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The installation structure of the ceramic panel curtain wall and the installation method of the ceramic panel curtain wall will be further described in detail below mainly in conjunction with the accompanying drawings and specific embodiments.

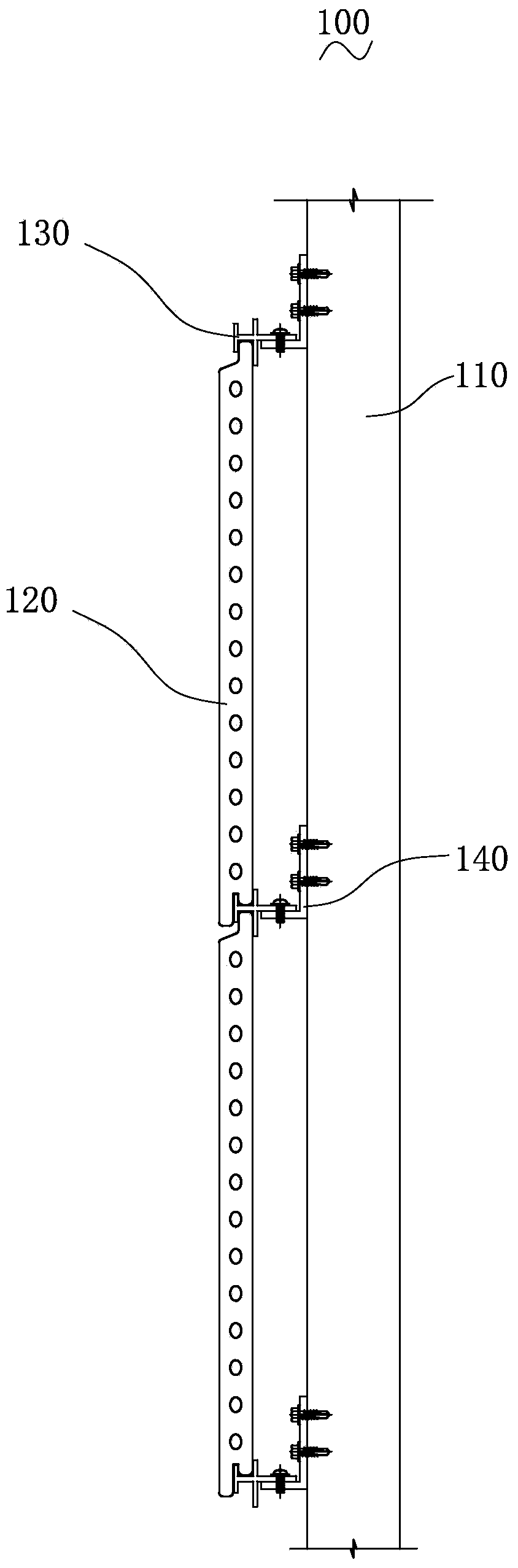

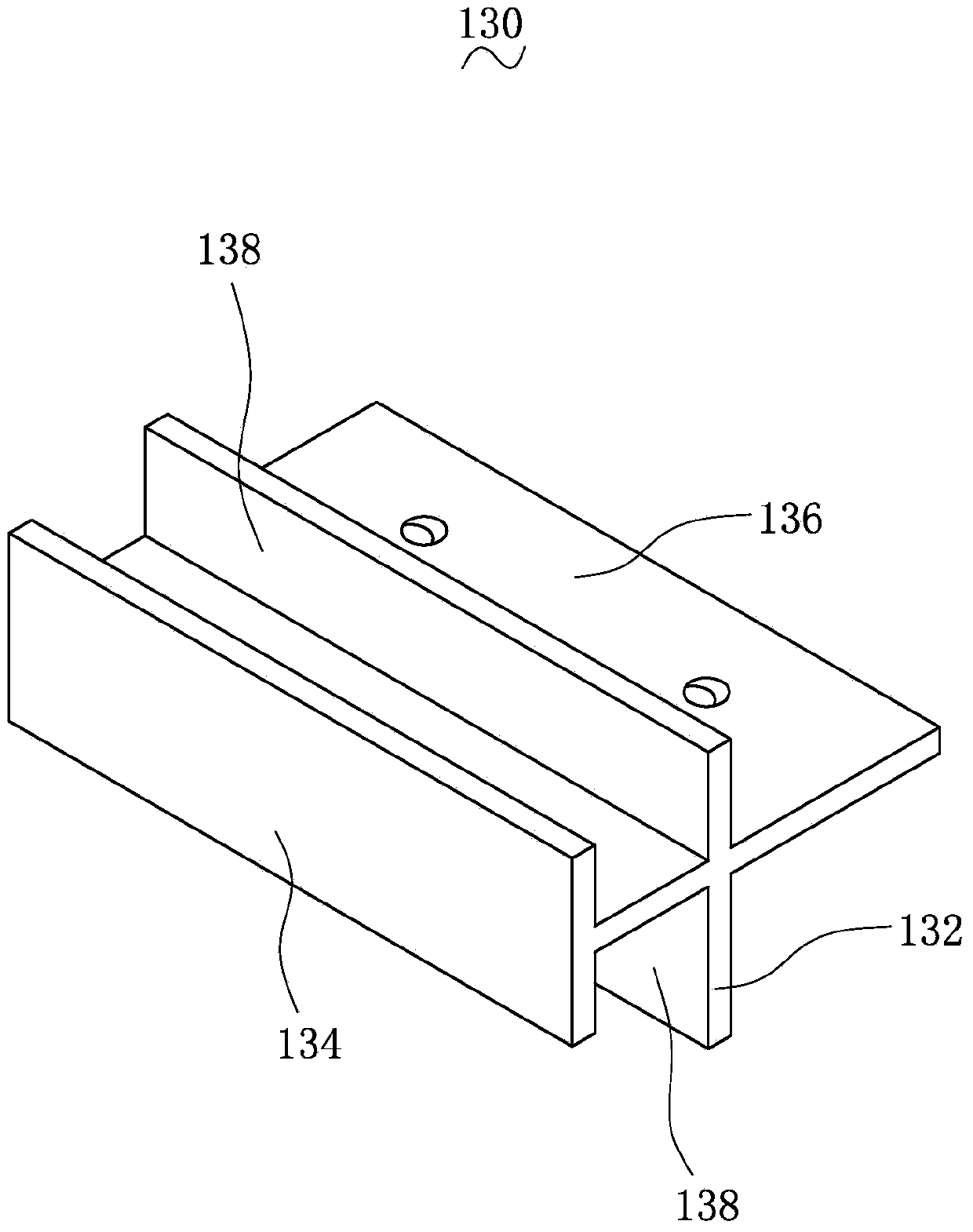

[0025] Such as figure 1 As shown, an installation structure 100 of a ceramic panel curtain wall according to an embodiment includes a keel 110 , a ceramic panel 120 and at least two connecting devices 130 .

[0026] The keel 110 is roughly in the shape of a long plate.

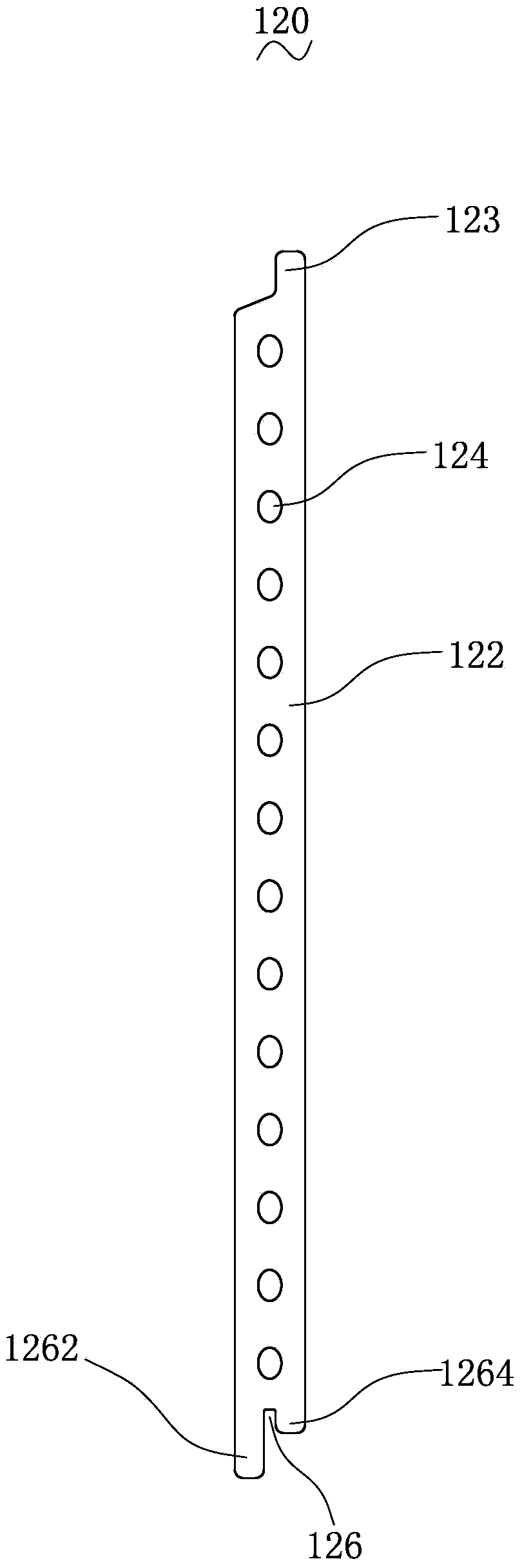

[0027] Please also refer to figure 2 , The ceramic plate 120 is roughly in the shape of a strip plate. Specifically, the ceramic plate 120 includes a plate-shaped body 122 and a clamping edge 123 disposed on an edge of the plate-shaped body 122 . The plate body 122 is provided with through holes 124 penetrating through two opposite sides of the plate body 122 , so that the weight of the ceramic plate 120 can be reduced. In a specific embodiment, there are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com