Flowing type efficient spiral material leveling machine

A leveling machine and flow-type technology, applied in the field of construction machinery, can solve the problems of large space, small operating range, and low efficiency, and achieve the effects of strong adaptability, good closing effect, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

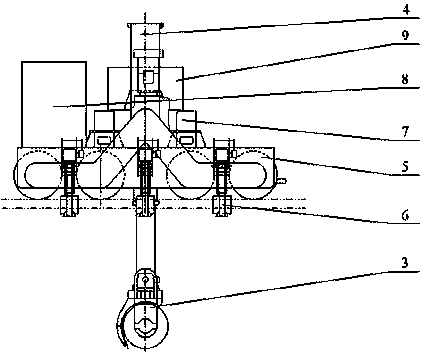

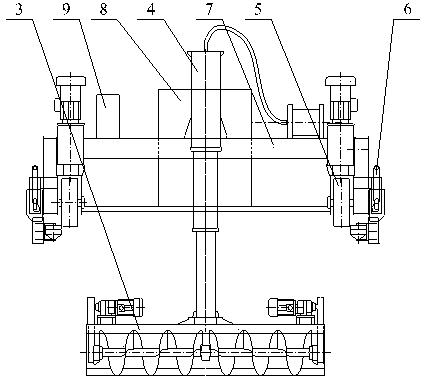

[0031] Such as figure 1 , figure 2 As shown, it includes: a screw pushing mechanism 3, a lifting mechanism 4, a traveling mechanism 5, an anti-deviation mechanism 6, a frame 7, a power device 8, an electric control device 9, and a control device. In the embodiment of the present invention, the power device 7 is a generator. The screw leveling machine is powered by its own generator, and uses the side of the train carriage 2 as a track to walk on the carriage 2, and unwind the materials in the carriage 2 above the carriage 2. At the same time, it can also complete a certain height difference and width interval. The cross-car movement realizes the leveling of the whole train.

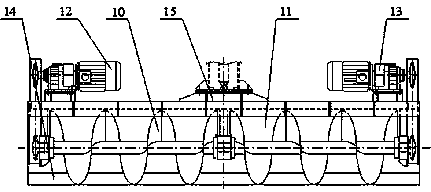

[0032] Such as Figure 7 , Figure 8 As shown, two sets of running gear 5 include wheel set 19, walking drive device 20 and sprocket wheel set 21 in total. A set of whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com