Clamp used for processing thin-wall sleeve component

A technology of thin-walled sleeves and fixtures, which is applied to metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the requirements of difficult and reliable positioning of thin-walled sleeve parts and the inability to ensure the roundness of thin-walled sleeve parts, Affecting parts processing quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

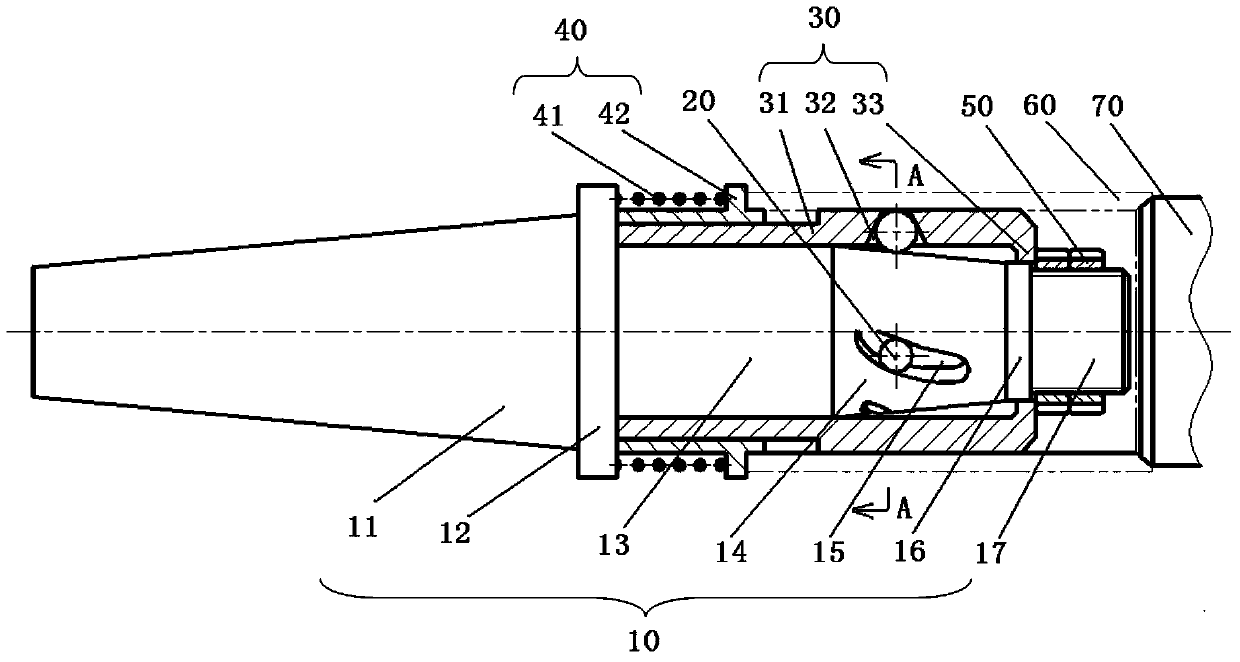

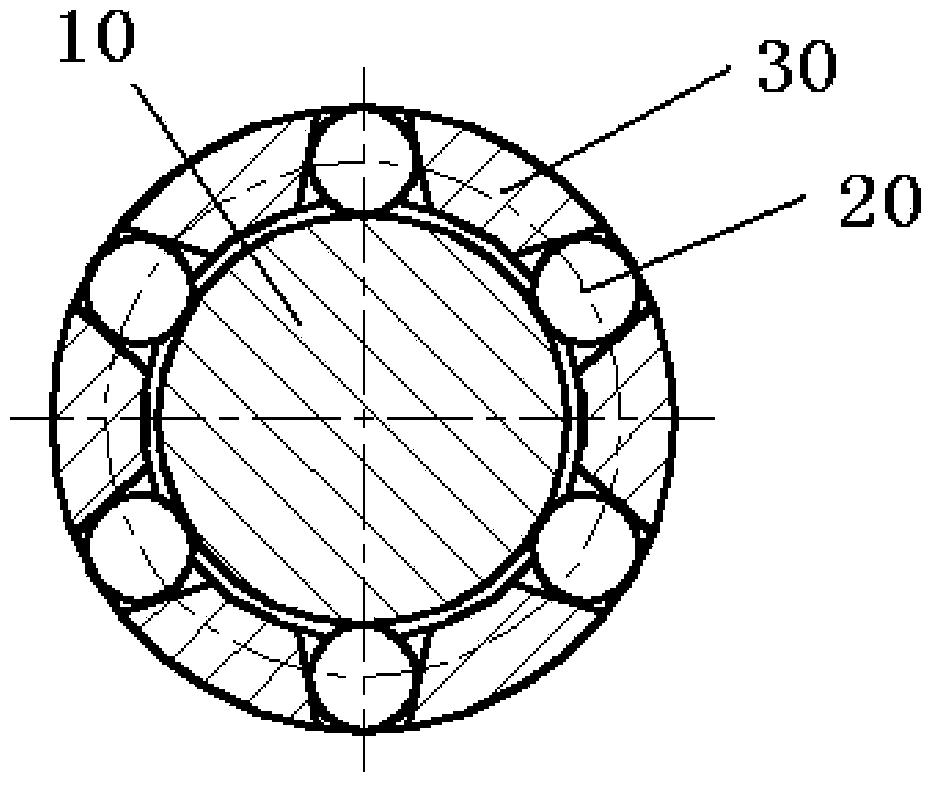

[0031] As another specific embodiment of the present invention, the clamp also includes a sleeve 30, the side wall of the sleeve 30 is provided with ball receiving holes 32 along the circumference of the sleeve 30, and each ball receiving hole 32 holds a One ball 20, and each ball 20 is in contact with the truncated portion 14, so that the ball 20 can protrude outward from the ball receiving hole 32 to form a fixed position for the thin-walled sleeve member 60 when being pressed to the mounting portion 11. Heart function. At this time, the sleeve 30 can be installed at the larger diameter of the frustum-shaped portion 14, that is to say, the sleeve 30 is sleeved on the frustum-shaped portion 14 and axially positioned using the larger diameter portion of the frustum-shaped portion 14. .

[0032] In addition, it is also possible to use figure 1 The shoulder portion 12 in the center is positioned axially. In this way, when the ball 20 is subjected to the cutting force transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com