Light emitting diode with heat release effect

A technology of light-emitting diodes and heat release, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of short working life, reduced transparency, and unreliability of LED chips, and achieve the effect of excellent heat release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

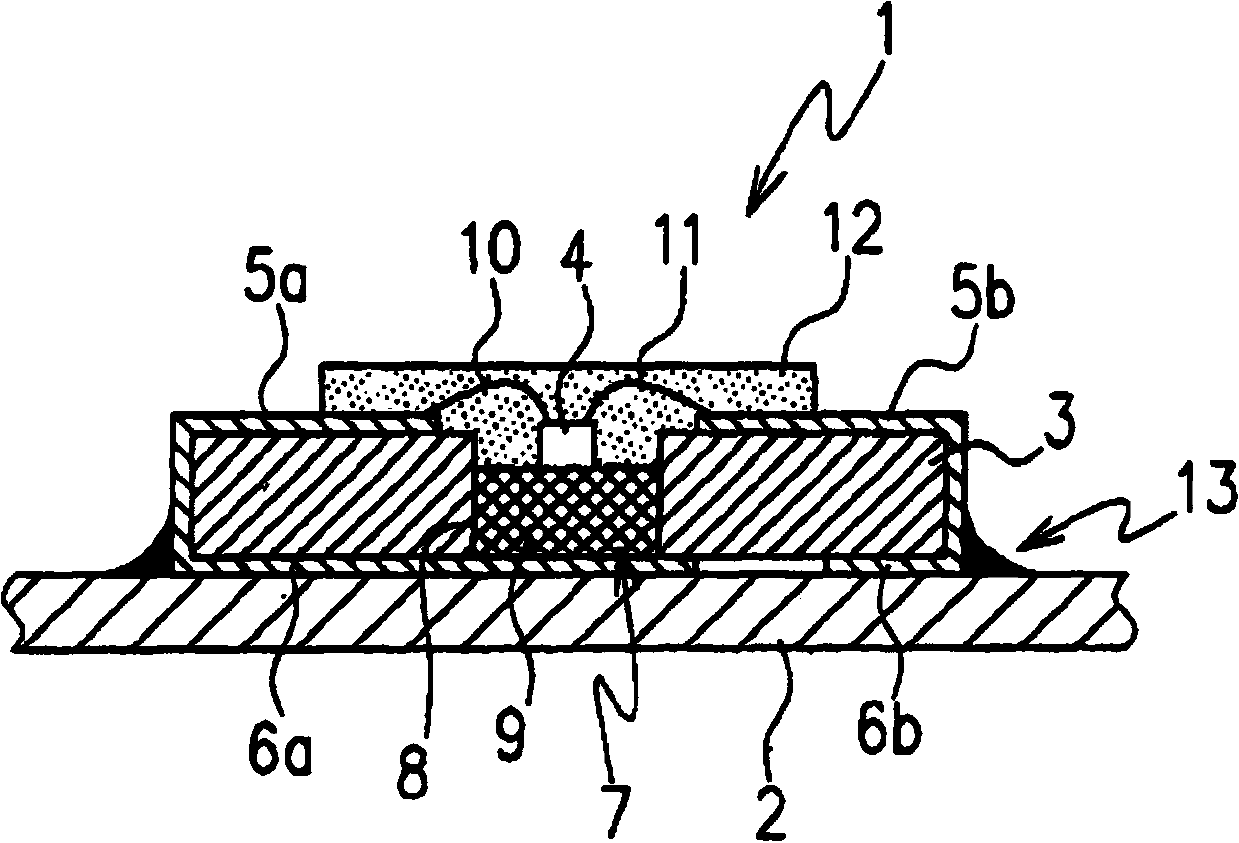

[0018] Such as figure 1 As shown, a light emitting diode 1 includes an LED chip 4 , an insulating circuit substrate 3 in which the LED chip 4 is disposed, and a printed wiring board 2 . The insulating circuit substrate 3 is made of glass epoxy, silicone or the like. Provided on the circuit substrate 3 are a pair of integrally formed upper and lower surface electrodes 5a, 6a and 5b, 6b.

[0019] The circuit substrate 3 has a heat radiation mechanism 7 . Radiation mechanism 7 comprises a heat radiation part 9, and it is in figure 1 is arranged in the storage portion 8 formed in the substantially central portion of the circuit substrate 3 in the embodiment shown in . The storage portion 8 includes, for example, a through hole formed in the circuit substrate 3 . When the heat radiation member 9 is inserted in the storage portion 8, the heat radiation member 9 is arranged to contact the surface of the printed wiring board 2 through the lower electrode 6a, the printed wiring b...

Embodiment 2

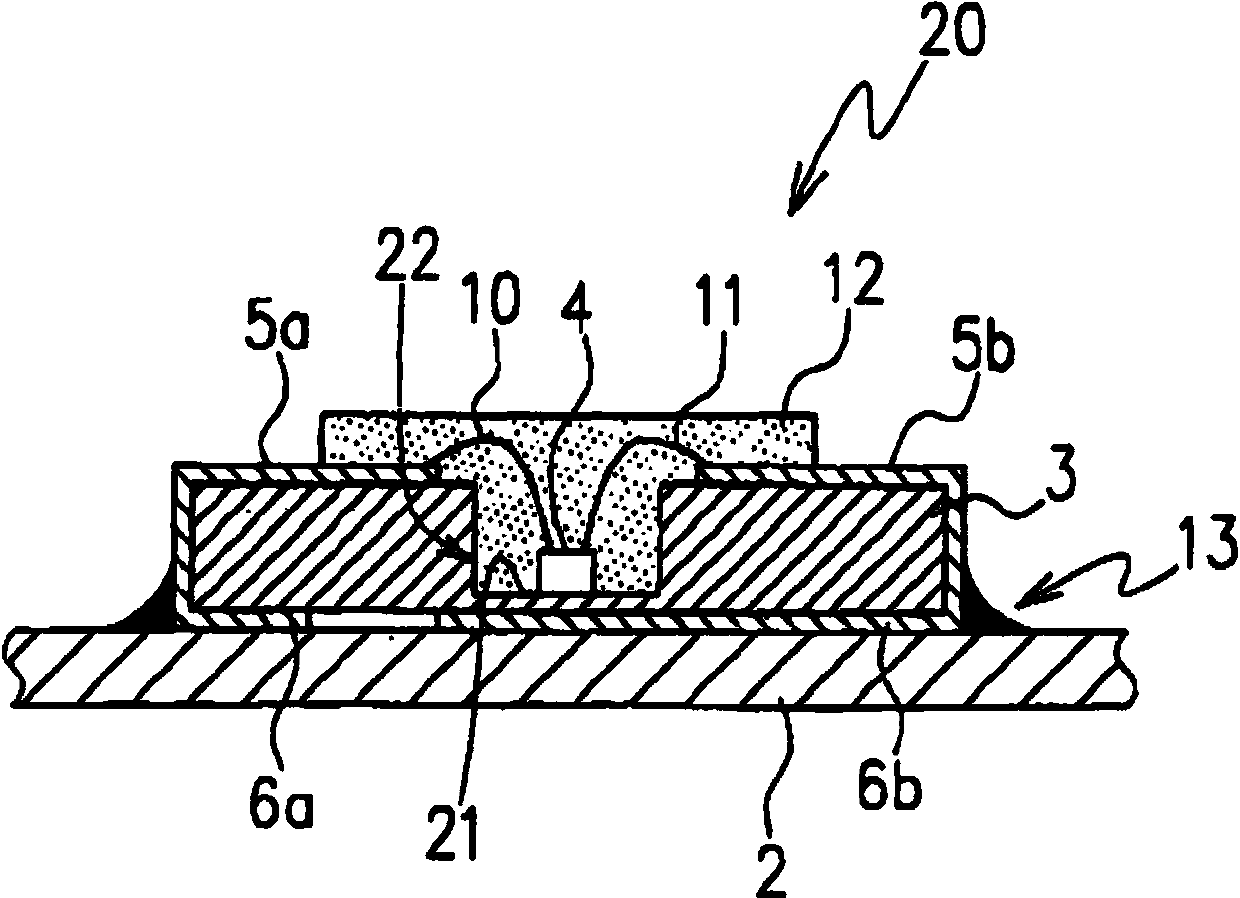

[0029] Such as figure 2 As shown, in the second embodiment, the same numerals are added to similar parts in the first embodiment.

[0030] The second embodiment differs from the first embodiment in that the heat radiation member 9 placed in the storage portion 8 of the through hole is not used. The recess 21 is formed by providing a recessed portion 22 so that a portion of the innermost portion of the circuit substrate 8 made of insulating glass epoxy resin remains as thin as possible. The LED chip 4 is inserted into the recessed portion 22 and mounted on the innermost side of the recess 21 . The LED chip 4 is fixed in the innermost part of the recess 2 by a transparent adhesive or the like, similar to the first embodiment described above.

[0031] Similarly as in the first embodiment, the sealing body 12 made of transparent resin is provided on the recessed portion 22 and the upper surface of the circuit substrate 3 to cover the LED chip 4 .

[0032] The light emitting di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com