Automatic control loading machine gearbox

An automatic controller and gearbox technology, which is applied in the direction of transmission control, transmission box, mechanical equipment, etc., can solve the problems of cumbersome operation, inability to perform automatic control operation, etc., achieves low cost, overcomes short working life, and is easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

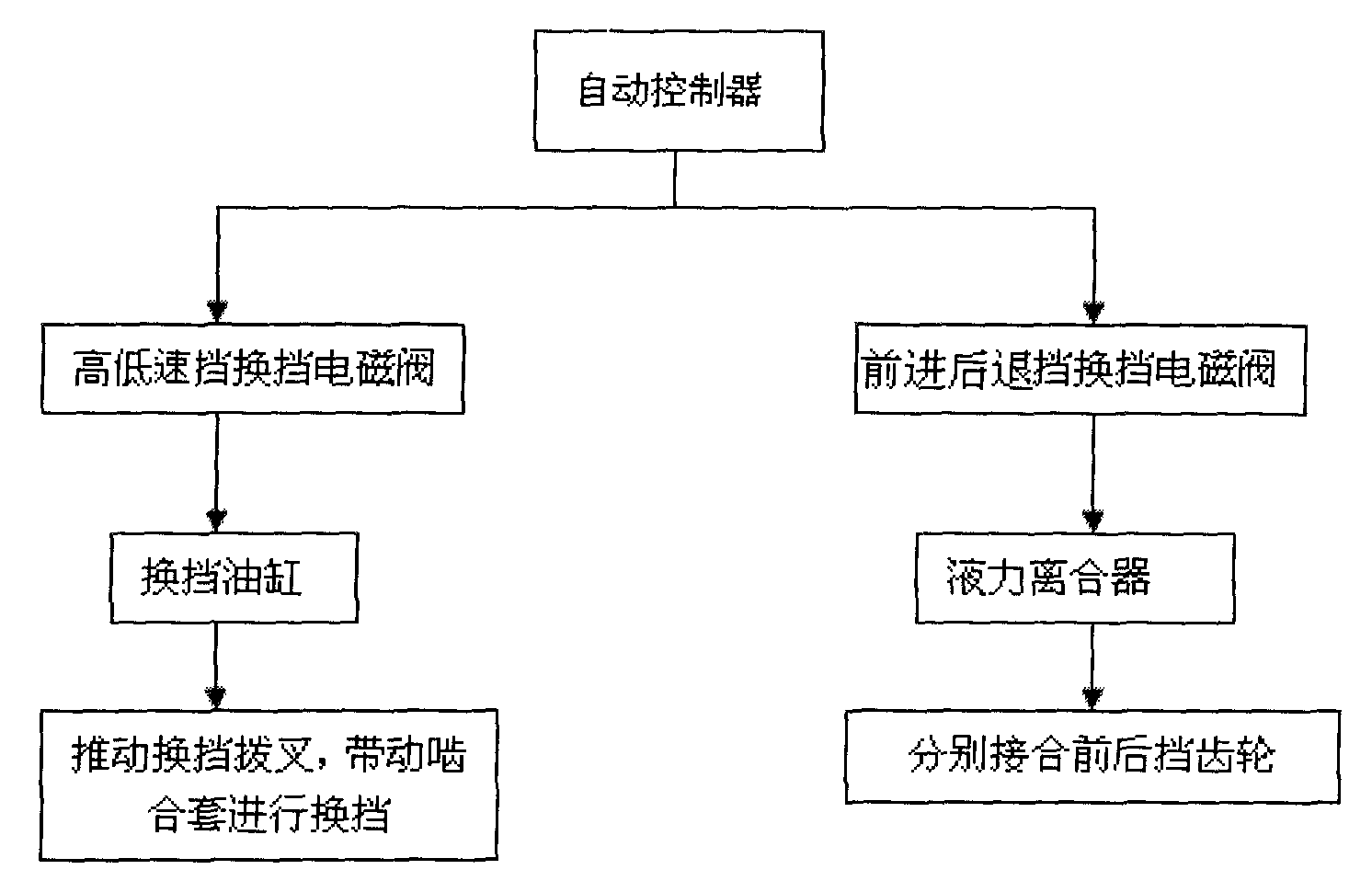

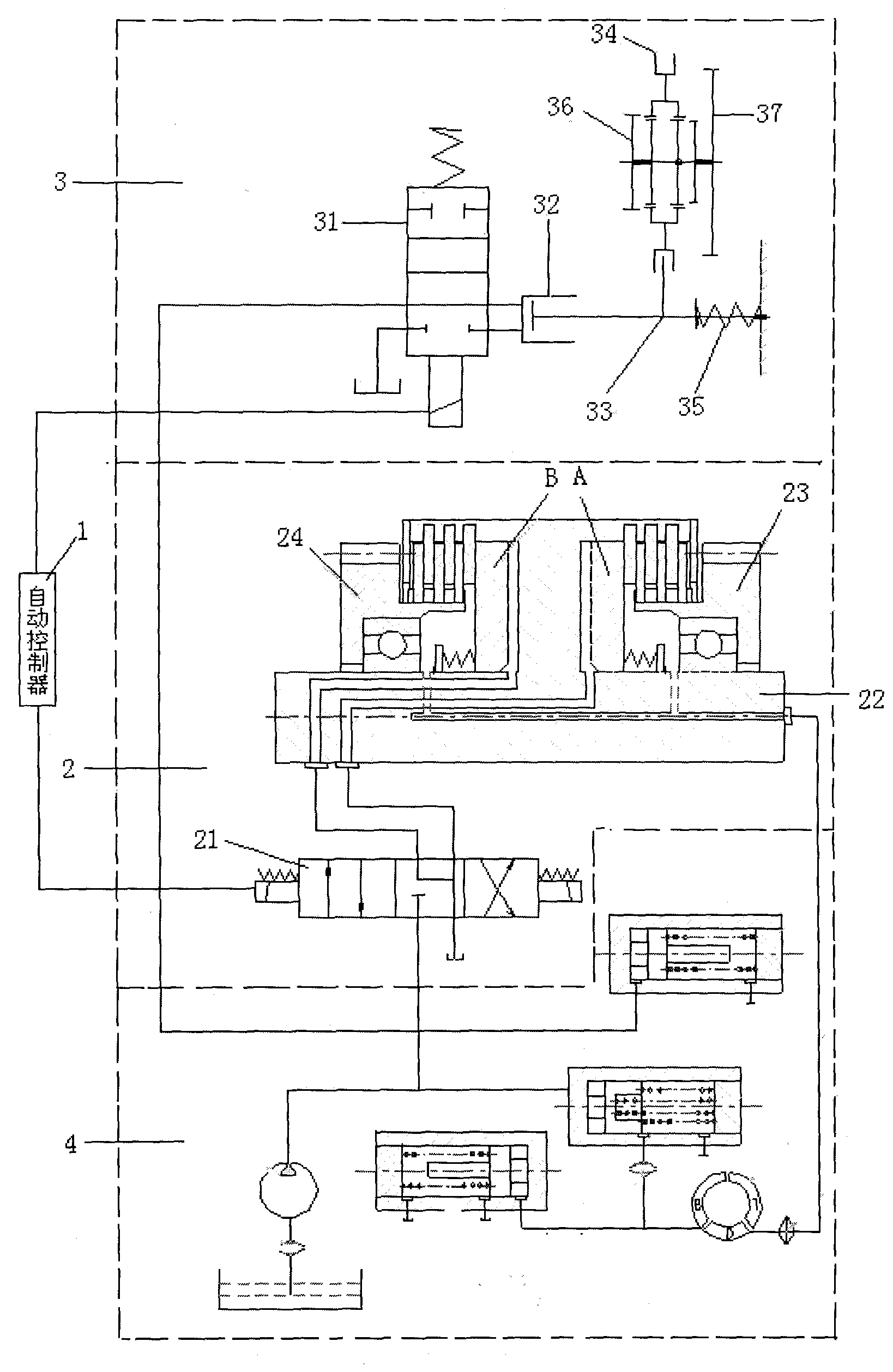

[0011] Such as figure 1 , 2 As shown, the forward and backward hydraulic shifting system 2 ( figure 2 Middle dotted line box) and high and low speed hydraulic shifting system 3 ( figure 2 The upper dotted box in ) is composed. The forward and reverse hydraulic shifting system controlled by the automatic controller is mainly composed of front and rear shift solenoid valves 21, hydraulic clutches 22, and front and rear gear sets. Piston group, wherein the first piston rod is connected with the forward gear 23, and the second piston rod is connected with the reverse gear 24; the high and low speed hydraulic shifting system connected and controlled by the automatic controller is mainly composed of high and low gear shift solenoid valves 31, The shift oil cylinder 32, the shift fork 33, and the engagement sleeve 34 are formed. The high and low gear shift solenoid valves are respectively connected to the shift oil cylinder piston rod to connect the shift fork, and the shift for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com