Novel three-phase-integrated autotransformer switch lead arranging method

A technology of autotransformer and switch leads, applied in the field of transformer manufacturing, can solve the problems of long time, expensive land acquisition, difficult site selection, etc., and achieve the effect of reducing the width of the fuel tank and reducing the width size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In the following, the present invention will be further illustrated through examples in conjunction with the drawings.

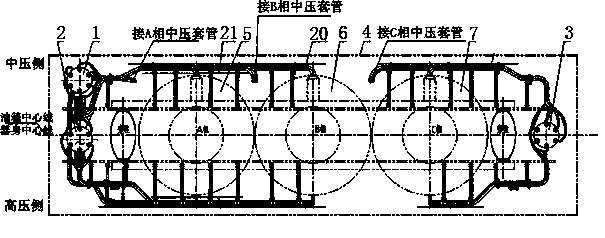

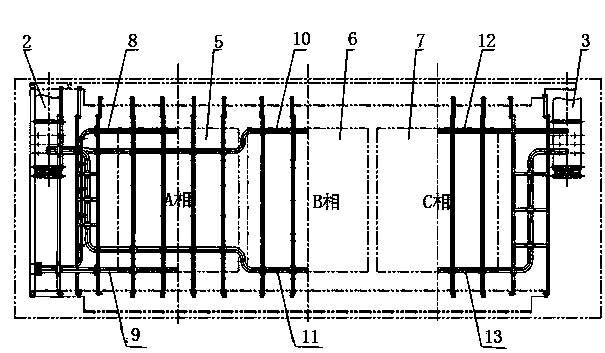

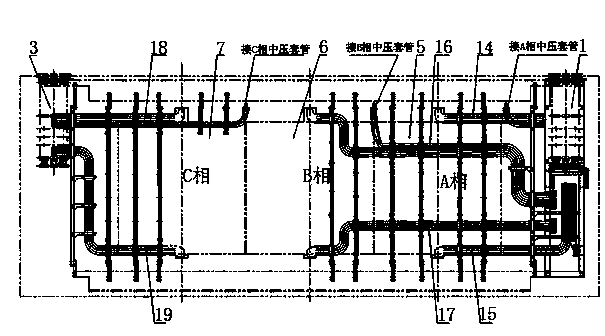

[0012] Reference attached figure 1 , Three single-phase voltage regulating switches, namely A-phase switch 1, B-phase switch 2, and C-phase switch 3. Place A-phase switch 1 and B-phase switch 2 on the left side of the long axis of the transformer facing the high voltage side, namely The left side of the A-phase body 5, where the A-phase switch 1 is arranged near the tank wall of the fuel tank 4, and the B-phase switch 2 is arranged near the center line of the body; the C-phase switch 3 is arranged on the right side of the long axis, namely The right side of the C-phase body 7 is close to the center line of the body; in order to divide the electric field and further reduce the width of the fuel tank, an insulating partition 20 between the lead and the tank wall is arranged between the lead and the fuel tank 4. An insulating partition 21 between the lead a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com