Method for simulation foundation pit excavation inner supporting experiments on basis of simple soil engineering centrifugal machine and special clamp thereof

A technology of geotechnical centrifuges and experimental methods, applied in the direction of machine/structural component testing, measuring devices, instruments, etc., can solve the problem of inability to simulate and reflect on-site excavation conditions well, hydraulic system leakage, and affect test results and other issues to achieve the effect of ensuring accuracy, convenient installation and operation, and simple working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

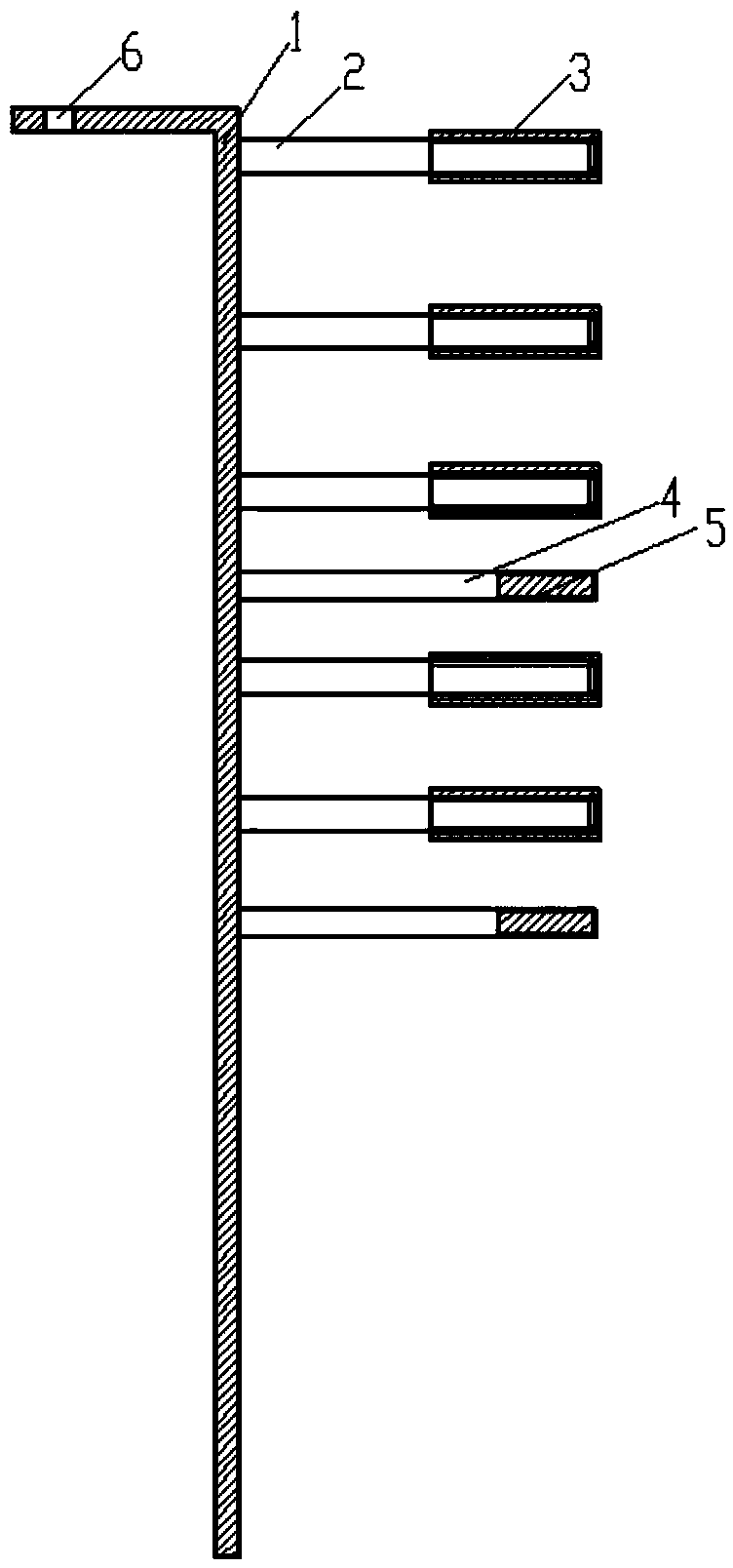

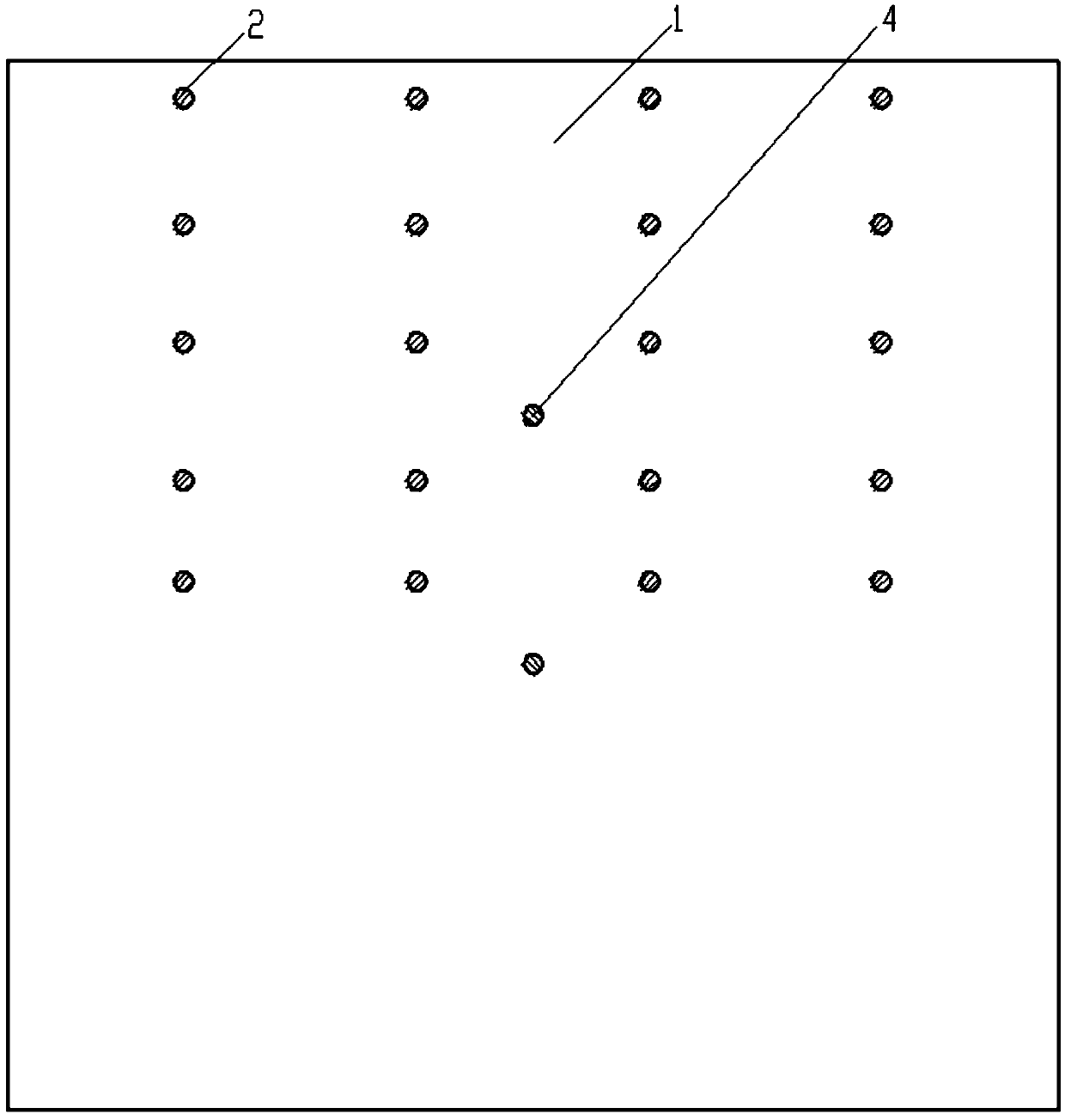

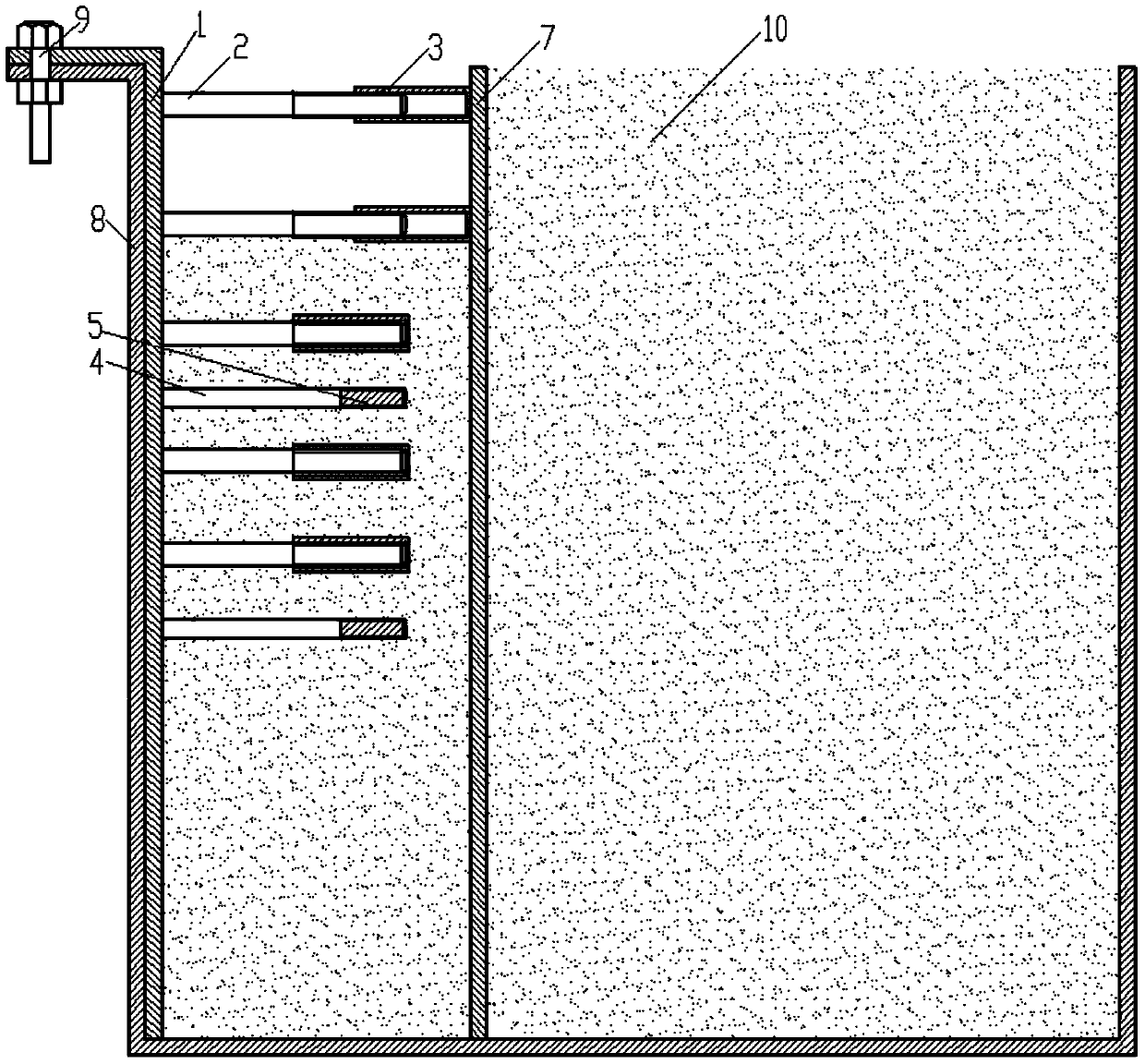

[0022] Figure 1~3 A specific embodiment of the invention is given. according to figure 1 , a geotechnical centrifuge test simulation foundation pit excavation internal support fixture, which consists of: fixed plate 1, internal support screw 2, external screw nut 3, displacement gauge support screw 4, laser displacement gauge 5 and so on. The fixed plate is made up of a steel plate, and a row of fixed screw holes 6 is reserved for extending out of the right end, which is used for fixing with the model box 8. It is required that the fixed screw hole 6 should be the same size as the screw hole on the model box 8, and the bolts 9 should be used to connect the two, such as figure 2 shown. The inner support screws 2 are arranged in four rows and five columns at a certain interval, and the cross-sectional area of the steel bar in each row is the same, (the area is converted according to the compressive stiffness (EA) of the material (reinforced concrete or section steel) used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com