Sealed oil catch for main shaft of wind driven generator

A wind turbine and main shaft sealing technology is applied in the field of sealing oil shields, which can solve the problems affecting the safe operation and civilized production of wind turbines, poor sealing effect, increased grease leakage, etc., and achieves simple structure and prevents grease leakage. , The effect of not increasing the sealing gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

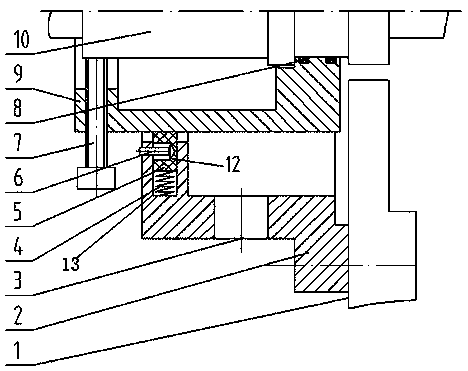

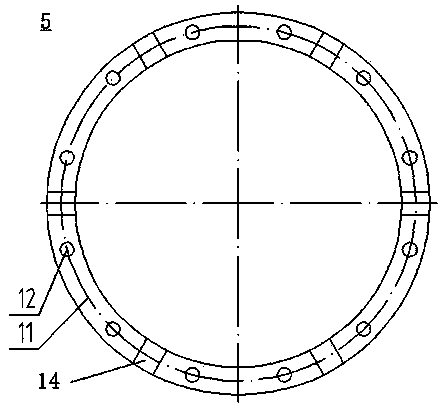

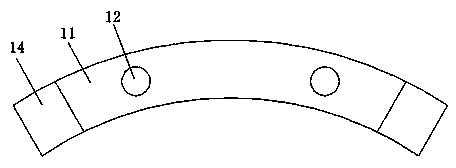

[0019] like figure 1 As shown, the wind turbine main shaft sealing oil shield of this embodiment includes a static ring 2 installed on the engine casing 1, a moving ring 9 fixed on the rotating shaft 10 and rotating with the rotating shaft 10; the moving ring 9 and the static ring 2 are provided with a floating sealing ring 5, the inner surface of the static ring 2 is provided with an annular groove 13, the floating sealing ring 5 is located in the annular groove 13, and the bottom of the annular groove 13 A spring 4 is arranged between the floating seal ring 5 .

Embodiment 2

[0021] like figure 1 As shown, the basic structure and function of the seal oil shield of the main shaft of the wind power generator in this embodiment are the same as those in Embodiment 1, the difference is that the moving ring 9 is provided with an adjusting screw 7, and the end of the adjusting screw 7 is on the top On the outer surface of the rotating shaft 10 , the adjusting screw 7 is screwed with the moving ring 9 to adjust the concentricity between the moving ring 9 and the rotating shaft 10 . Two O-rings 8 are arranged between the moving ring 9 and the rotating shaft 10 .

Embodiment 3

[0023] like figure 1 As shown, the basic structure and function of the wind turbine main shaft sealing oil shield of this embodiment are the same as those of Embodiments 1 and 2, the difference is that the outer surface of the floating sealing ring 5 is provided with a plurality of circular grooves 12, The outer surface of the annular groove 13 of the static ring 2 is provided with a plurality of pin holes, the pin holes are correspondingly arranged with the circular groove 12, and the positioning pin 6 is arranged in the pin hole, and the positioning pin 6 is inserted into the circular groove 12. shaped groove 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com