Torsion damper

A technology of torsional shock absorber and mass block, applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve problems such as transmission shaft jitter, natural frequency rubber damage, cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

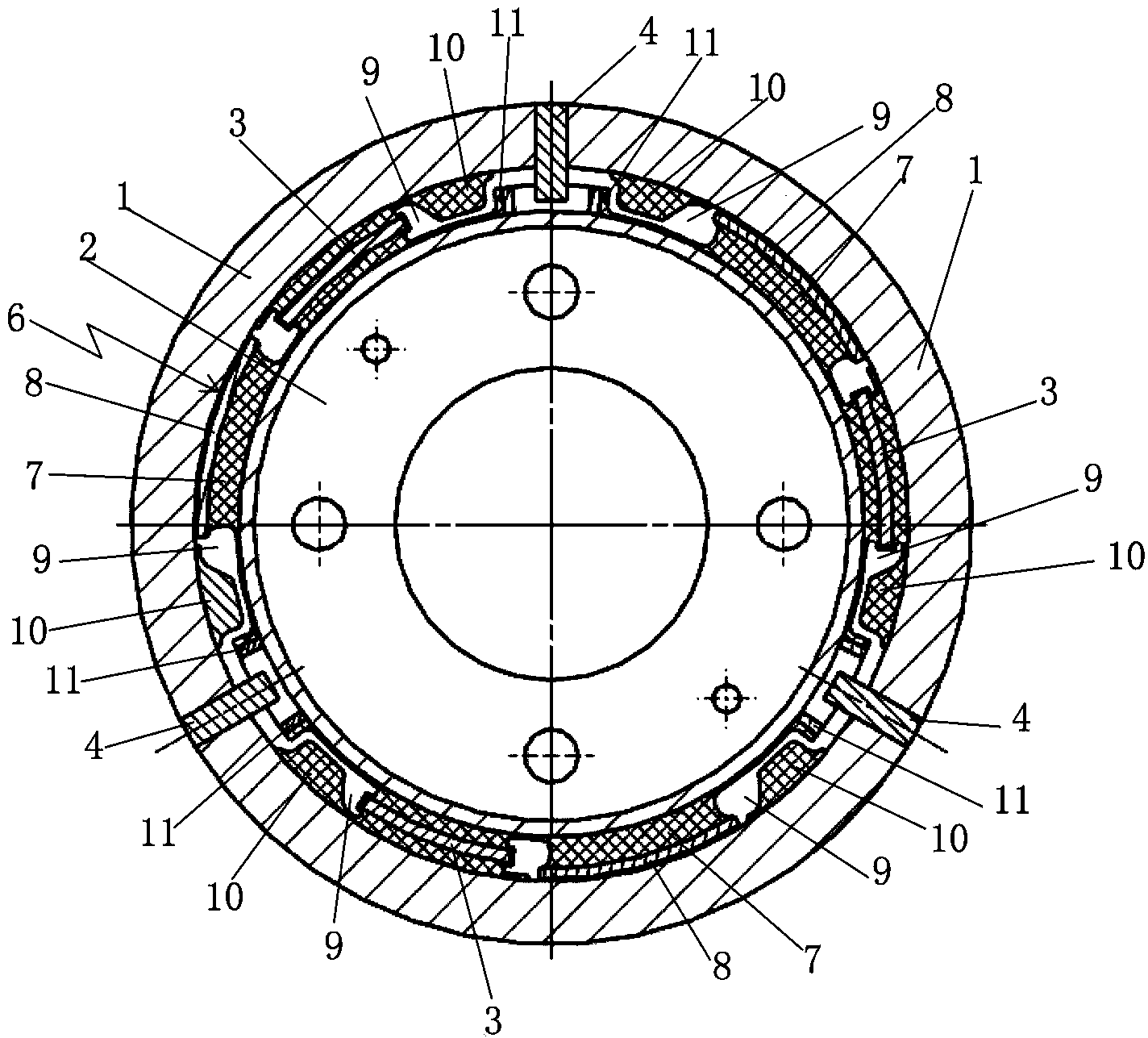

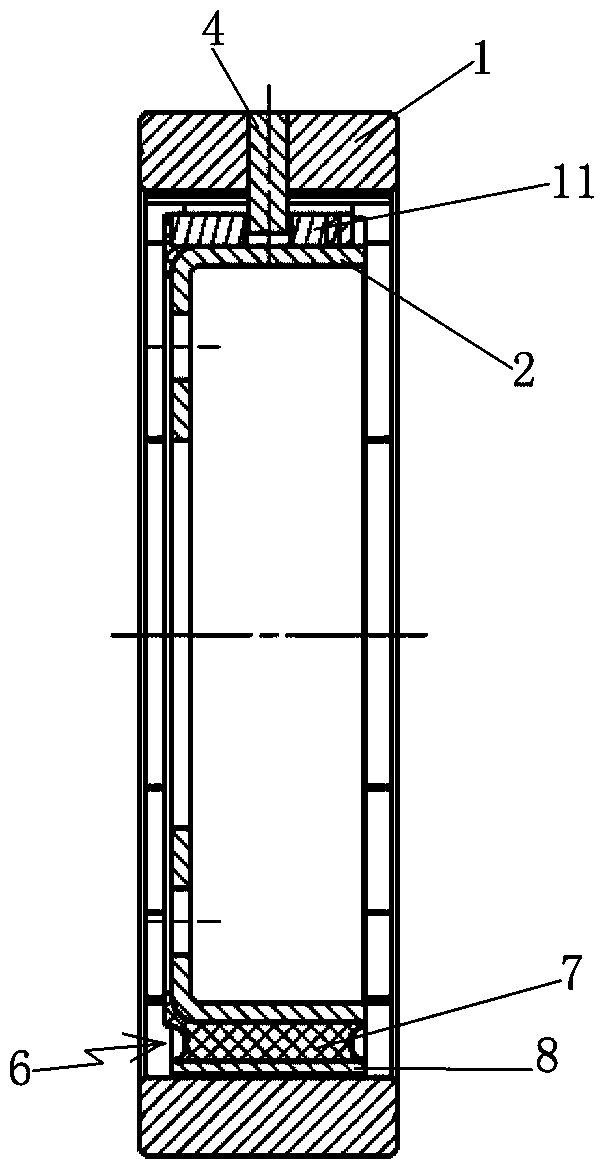

[0025] The following with attached Figure 2 to Figure 4 A torsional vibration damper of the present invention is further described in detail.

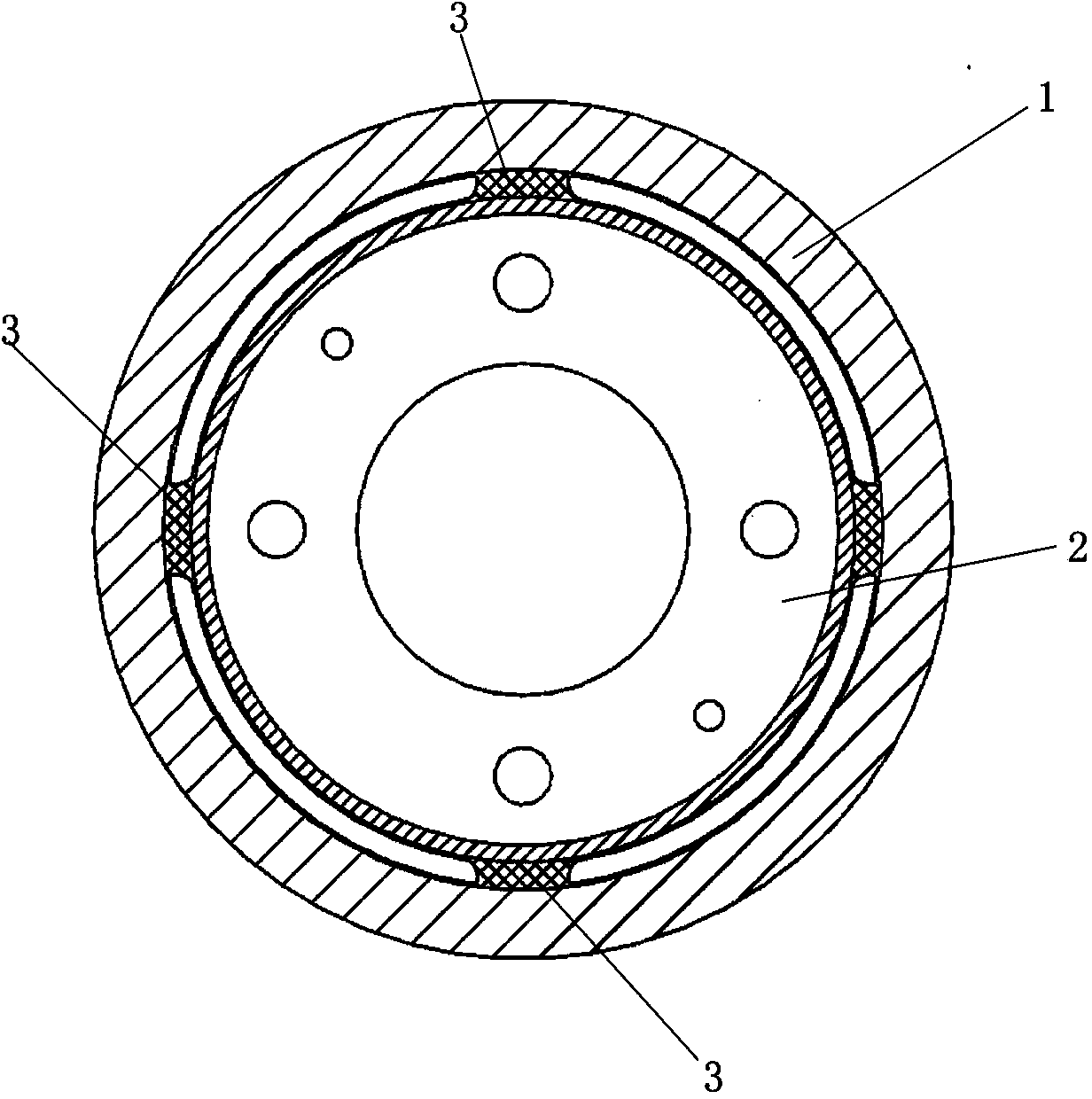

[0026] A kind of torsional shock absorber of the present invention, please refer to Figure 2 to Figure 4 , including a mass block 1, a connecting flange 2, and a natural frequency rubber block 3 arranged between the mass block 1 and the connecting flange 2 along the outer periphery of the connecting flange 2, the connecting flange 2 Coaxially arranged in the mass block 1, an axial limit device, a radial limit device and a torsion limit device are arranged between the connecting flange 2 and the mass block 1, and the axial limit The number of the device, the radial limiting device and the twist limiting device is at least one. In this way, during the operation of the vehicle, the axial limit device reduces the axial tearing of the natural frequency rubber block 3 of vibration damping, improves its life, and it also has a limit prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com