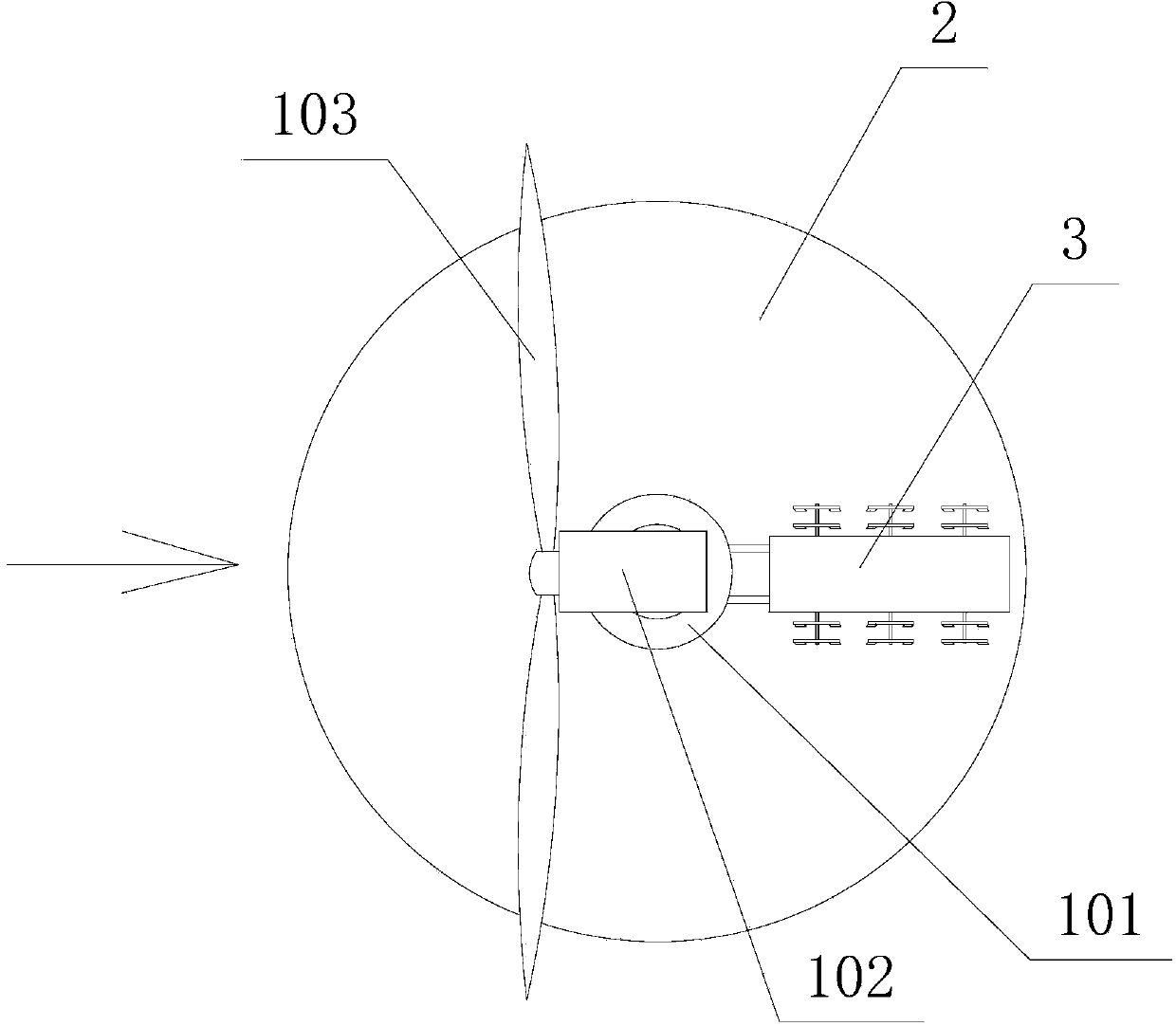

Wind power generation device

A technology of wind power generation device and power generation device, which is applied in the direction of wind power generator components, wind power generation, wind power engine, etc., can solve the problems of high utilization rate of wind power and low utilization rate of low altitude, and achieve high power generation efficiency, improvement effect and space utilization Good rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, an annular locking groove 1011 is provided on the side wall of the column 101, and a locking block 45 is provided at the end of the sleeve 41, and the locking block 45 is slidably fitted in the annular locking groove 1011; the cross section of the annular locking groove is T-shaped, correspondingly, the longitudinal section of the clamping block 45 is also T-shaped; in order to prevent abrasion, improve the lubricating performance, and prevent from being stuck when sliding, a pressing plate 46 is provided between the clamping groove 1011 and the end surface of the clamping block 45, The pressing plate is made of self-lubricating material, preferably graphite or polytetrafluoro material.

Embodiment 2

[0043] In the second embodiment, a circular ring is provided, and the circular ring is rotatably set on the side wall of the column 101 through a bearing, and the sleeve 41 is fixedly connected to the circular ring to realize rotation around the column.

[0044] In order to improve the stability performance, there are two connecting rods and they are located in the same horizontal plane.

[0045] The present invention also provides a wing wheel structure, and the specific structure is as follows: a fixed shaft sleeve 3031 with a central hole is provided, a keyway for radial positioning is provided in the central hole of the fixed shaft sleeve 3031, and the side wall of the fixed shaft sleeve 3031 There are at least three wing shafts 3032 evenly distributed in the circumferential direction, preferably four, and two blades 3033 facing the same direction are rotatably installed on each wing shaft 3032, and the rotation angle of each blade 3033 is less than or equal to 90 degrees, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com