Method for remote filling of explosion-proof compression-resistant closing of coal mine

A filling method and remote technology, applied in mining installations, mining equipment, earthwork drilling, etc., can solve problems such as difficulty in effectively eliminating air leakage, weak anti-explosion and impact resistance, and increasing the difficulty of gob management, reducing The effect of sealing engineering quantity and sealing time, strong fluidity and strong compressive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

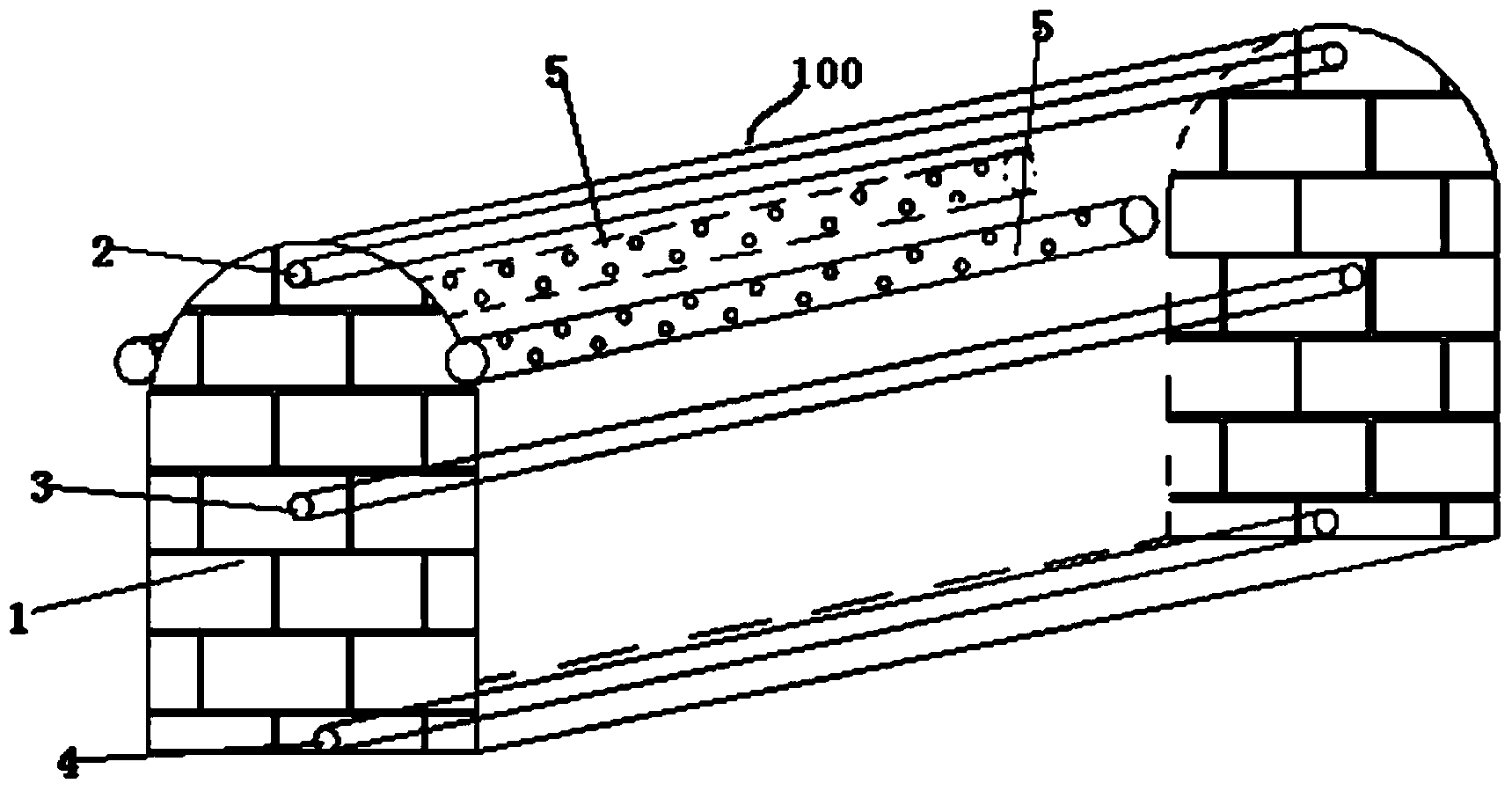

[0011] Such as figure 1 As shown, the remote filling method of explosion-proof and pressure-resistant airtight coal mine provided by the invention includes the following contents:

[0012] 1) For the roadway where the fire occurs, build a closed wall 1 on both sides of the roadway 100 that needs to be sealed. On the two closed walls 1, a measure hole 2, an observation hole 3 and a A drain hole 4, and the drain hole 4 is arranged at the bottom of the airtight wall 1;

[0013] 2) The corresponding two measure holes 2, two observation holes 3 and two drain holes 4 on the two closed walls 1 are connected by circular pipes;

[0014] 3) A number of conduits 5 are set between the closed wall 1 on the side away from the fire zone and the side wall of the roadway 100. One end of the conduit 5 enters the tunnel 100 between the two closed walls 1, and the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com