Production process for anti-ultraviolet flame-retardant light-resistant curtain shell fabric

A production process, anti-ultraviolet technology, applied in the direction of fiber type, textile and paper making, fiber treatment, etc., can solve the problems affecting the color, pattern, fading and degradation of curtain fabric, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

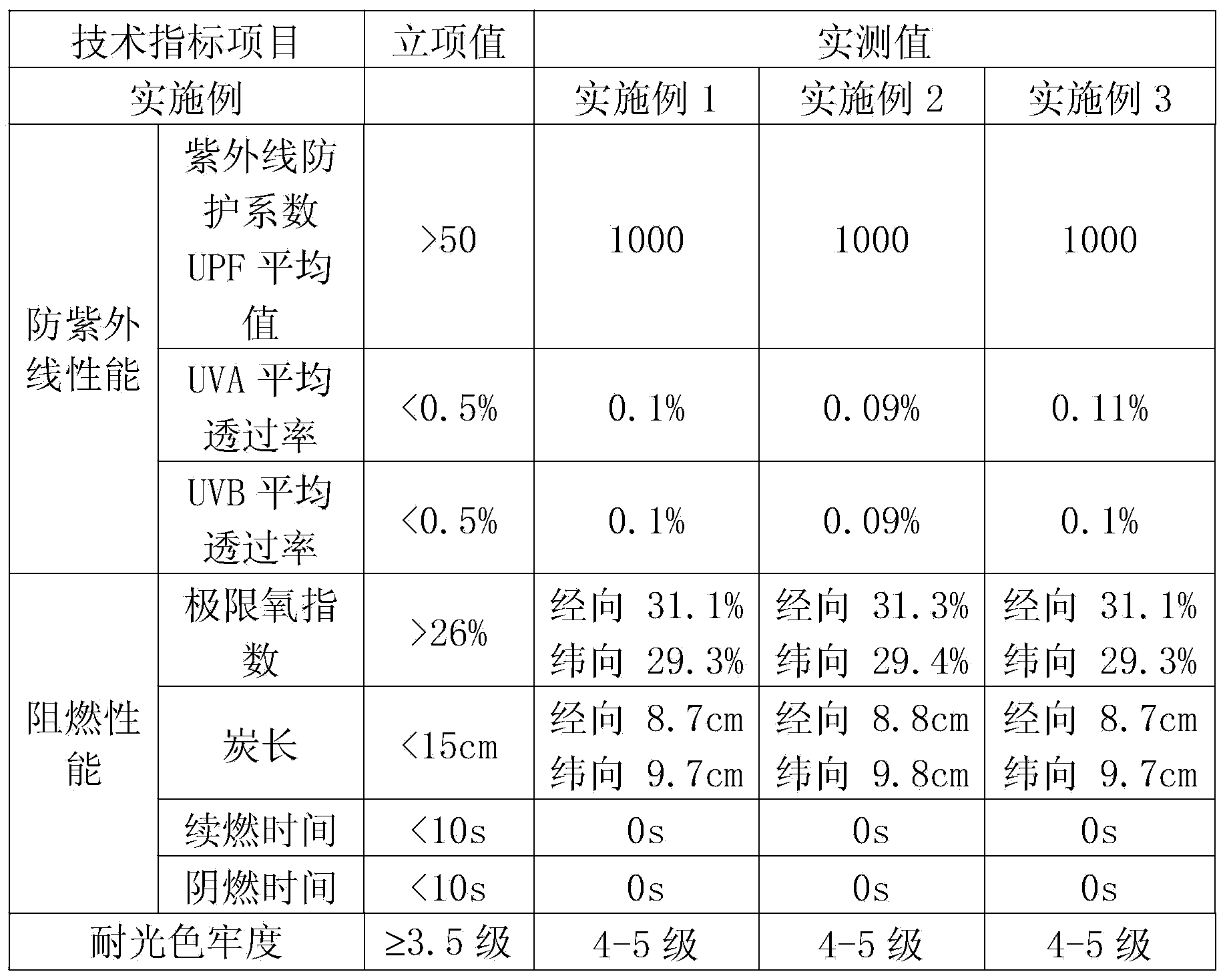

Examples

Embodiment 1

[0017] 3 parts by weight of phosphorus-free flame-retardant polyester fibers, 5 parts by weight of polyacrylonitrile fibers, 2 parts by weight of fine sulfur cotton, and 0.3 parts by weight of flame-retardant nylon are mixed and spun into yarns, and then the yarns are spun into Semi-finished fabrics;

[0018] Weigh each raw material separately and configure it into a finishing solution. The components of the finishing solution are as follows: paint 45g / L, paint white FTW 4g / L, acrylate adhesive 15g / L, urea 20g / L, glycerin 2g / L, Gemini Cationic softener 40g / L, flame retardant 3g / L, micronano oxide 15g / L, alkyl polyoxyethylene ether succinate sulfonate 1g / L, tribenzylphenol polyoxyethylene ether 2.5g / L L;

[0019] Add the penetrating agent JFC to the above finishing solution, so that the JFC content in the finishing solution reaches 1g / L. Put the above-mentioned semi-finished fabric into the finishing solution for two dipping and two rolling. The rolling rate is 75%. Re-baking...

Embodiment 2

[0021] 3 parts by weight of phosphorus-free flame-retardant polyester fibers, 5 parts by weight of polyacrylonitrile fibers, 2 parts by weight of fine sulfur cotton, and 0.3 parts by weight of flame-retardant nylon are mixed and spun into yarns, and then the yarns are spun into Semi-finished fabrics;

[0022] Weigh each raw material respectively and configure it into a finishing solution. The components of the finishing solution are as follows: paint 50g / L, paint white FTW 3g / L, acrylate adhesive 25g / L, urea 15g / L, glycerin 2.5g / L, Gemini cationic softener 38g / L, flame retardant 3.5g / L, micronano oxide 8g / L, alkyl polyoxyethylene ether succinate sulfonate 1.5g / L, tribenzylphenol polyoxyethylene ether 2.5g / L;

[0023] Add the penetrating agent JFC to the above finishing solution, so that the JFC content in the finishing solution reaches 1g / L. Put the above-mentioned semi-finished fabric into the finishing solution for two dipping and two rolling. The rolling rate is 75%. Re-b...

Embodiment 3

[0025] 3.5 parts by weight of phosphorus-free flame-retardant polyester fiber, 4 parts by weight of polyacrylonitrile fiber, 2 parts by weight of refined sulfur cotton, and 0.3 parts by weight of flame-retardant nylon are mixed and spun into yarn, and then the yarn is spun into Semi-finished fabrics;

[0026] Weigh each raw material separately and configure it into a finishing solution. The components of the finishing solution are as follows: paint 55g / L, paint white FTW 2g / L, acrylate adhesive 30g / L, urea 20g / L, glycerin 3g / L, Gemini Cationic softener 35g / L, flame retardant 4g / L, micronano oxide 2.5g / L, alkyl polyoxyethylene ether succinate sulfonate 2g / L, tribenzylphenol polyoxyethylene ether 2.5g / L;

[0027] Add the penetrating agent JFC to the above finishing solution, so that the JFC content in the finishing solution reaches 0.5g / L. Put the above-mentioned semi-finished fabric into the finishing solution for two dipping and two rolling. The rolling rate is 75%, and it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com