Composite co-extrusion tubular plastic lamp shade extrusion die

An extrusion die and round tube technology, which is applied in the field of compound co-extrusion round tube plastic lampshade extrusion mould, can solve the problems of monotony, fragile glass lampshade and inability to process, and achieve good light transmission, beautiful appearance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

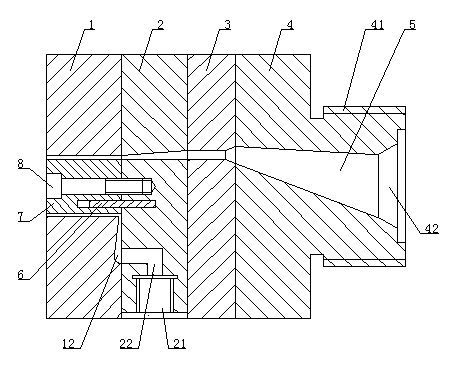

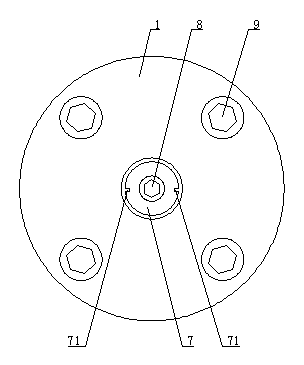

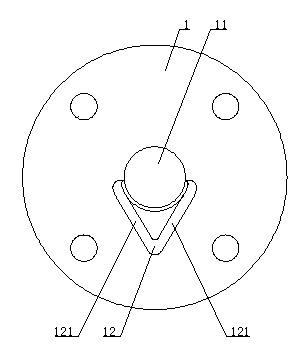

[0009] see Figure 1 to Figure 3 , the present invention includes a mouth template 1, a manifold 2, a transition plate 3 and a mold body 4, and also includes a positioning pin 6, a mandrel 7, a small screw 8 and several long screws 9, in the mouth template 1, the manifold 2 1. Between the transition plate 3 and the mold body 4, a main channel 5 passing through from left to right is provided, an external thread 41 is provided on the outer circular surface of the right part of the mold body 4, and an external thread 41 is arranged on the right end of the inner hole of the mold body 4. There is a main feed port 42, the manifold 2 is provided with a side feed port 21 and a side flow channel 22, the mouth template 1 is provided with a round hole 11 and an end face flow channel 12, and the end face flow channel 12 includes Two symmetrically arranged branch channels 121, two symmetrical grooves 71 are provided on the mandrel 7, one end of the end surface flow channel 12 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com