Open type abrasive belt steel rail grinding device

An abrasive belt and rail technology, applied in the field of open abrasive belt rail grinding devices, can solve the problems of increasing rail grinding costs, high requirements on grinding wheel formulation and manufacturing process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The polishing device proposed by the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

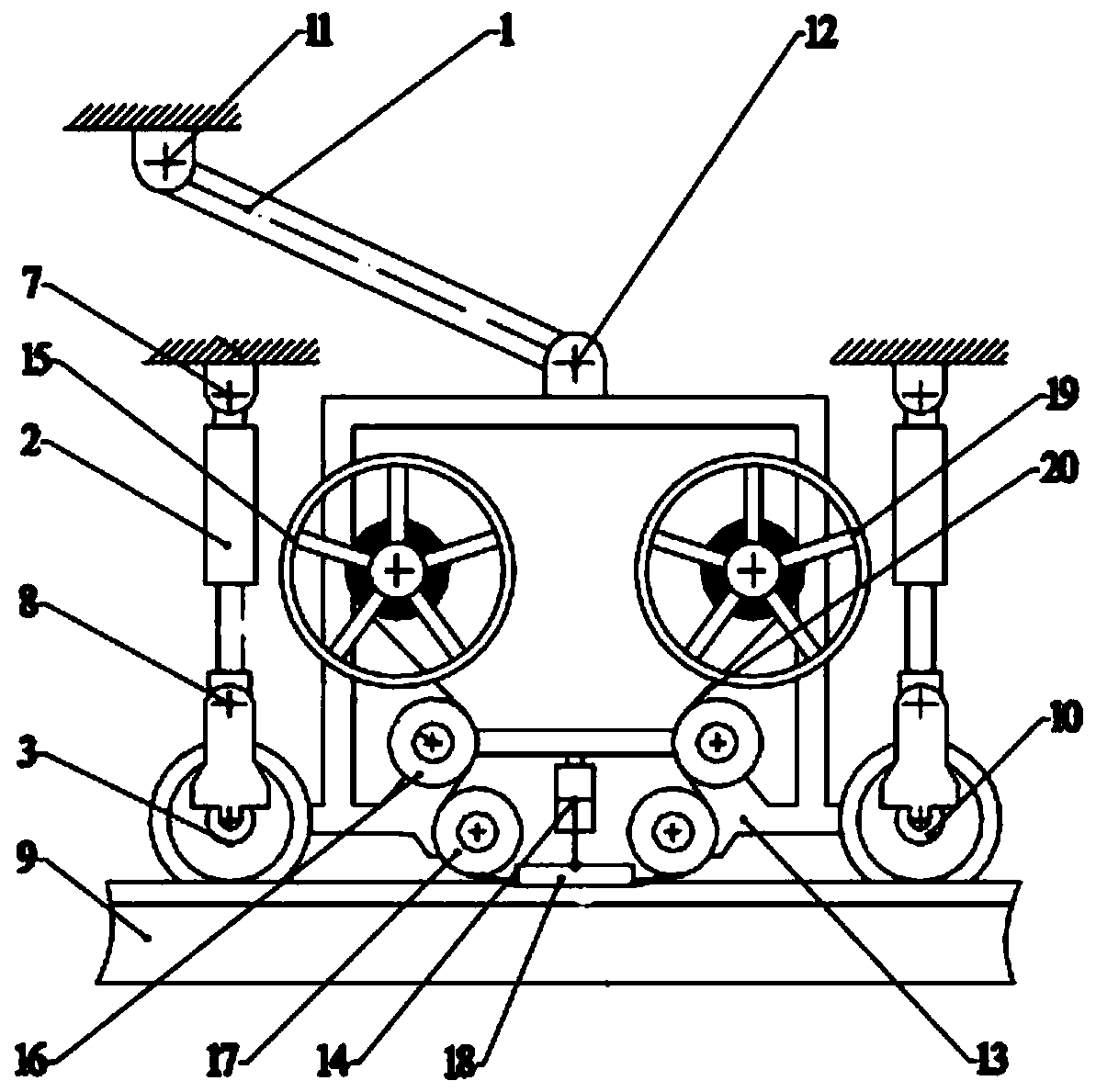

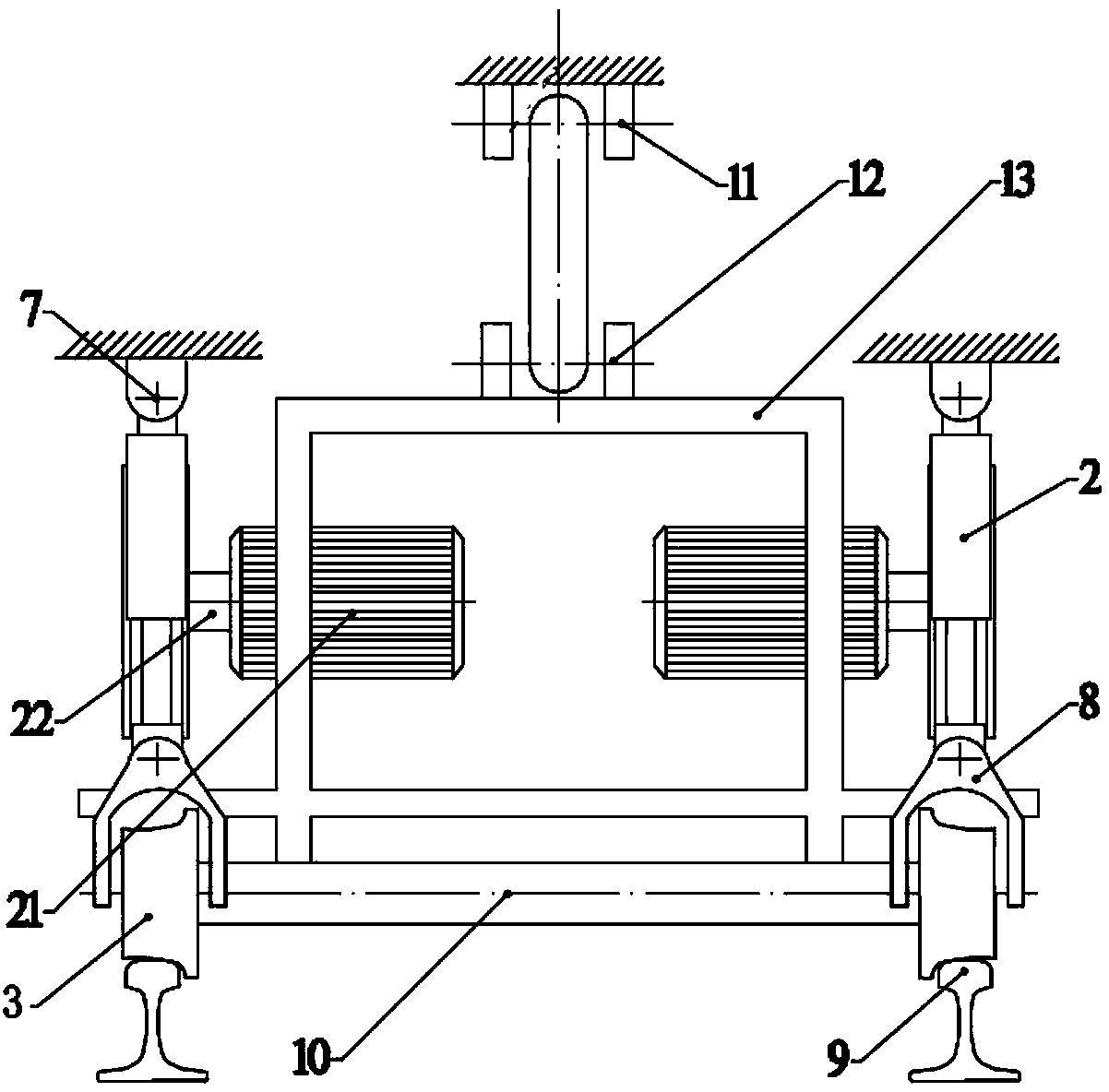

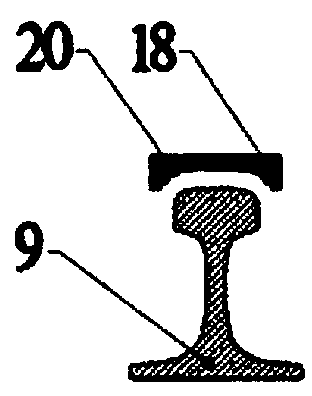

[0018] Such as figure 1 and figure 2 Shown are the side and front structural views of the grinding device proposed by the present invention; the device is composed of a traction device, a lifting device, a walking mechanism, an abrasive belt transmission mechanism, and contact pressing parts between the abrasive belt and the rail; the traction device and the lifting device are respectively It is connected with the corresponding fixed position of the grinding train, and the traveling mechanism is respectively connected with the traction device, the lifting device, and the belt transmission mechanism, and the grinding operation is carried out by the contact and compression of the belt through its transmission mechanism and the rail.

[0019] The traction device is composed of a traction rod 1, a third connecting part 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com