Gentle type decontamination processing method for meat product

A processing method and technology for meat products, which are used in food preservation, meat/fish preservation, and chemical preservation of meat/fish, etc., can solve the problems of poor elasticity of meat fibers, affecting product taste, and high heat sterilization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

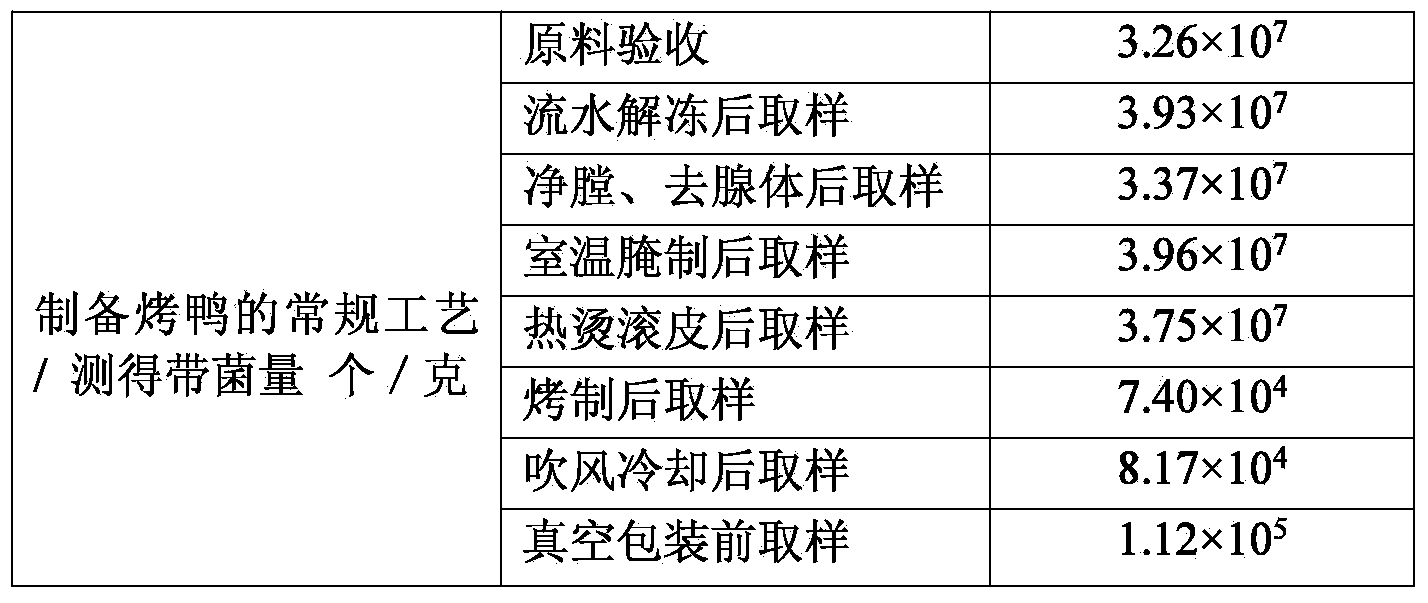

[0031] Embodiment 1 (note the numbering): the mild formula reducing bacteria processing method of roast duck (roasted product)

[0032] At first, provide prior art to make the conventional processing technological process of roast duck, it comprises the following steps:

[0033] Acceptance of raw materials: obtain the qualification of the supplier, the inspection and quarantine certificate of the current batch of products, and the vehicle disinfection certificate——Put the raw materials at -18°C for low-temperature refrigerated storage——Exit inspection: Conduct sensory inspection on the outgoing duck blanks— - Thawing in running water: the frozen duck is ready for about 10 hours, and the fresh duck is cooked immediately - Evisceration and gland removal: rinse the duck blank with running water, eviscerate the duck blank twice, and remove the glands in the anus of the duck blank - Marinate: in At room temperature, marinate for 12 hours, use 0.2 kg of salt for each roast duck (100...

Embodiment 11

[0039] Embodiment 11 (note numbering):

[0040] Acceptance of raw materials, refrigerated storage (-18°C) and sensory inspection of out-of-warehouse;

[0041] Refrigeration and thawing: Take duck blanks that have passed the sensory inspection at -18°C and place them in a refrigerator at 4°C for 18 hours;

[0042] Clean water disinfection: here, it is necessary to eviscerate and remove the glands of the refrigerated and thawed duck blanks, and then soak and disinfect the duck blanks with an aqueous solution of sodium hypochlorite complex with a pH value of 4.6 at 100ppm (effective concentration of chloride ions) for 10 minutes, and then wash with clean water;

[0043] Refrigerated marinating: put the duck blank in a refrigerator at 0°C for 5 hours, and use 50g of salt for every 1000g of duck blank;

[0044] Blanching and disinfection: put the duck base obtained by cold storage and marinating into boiling water, add 0.5% edible alcohol compound and 0.5% glycine compound into the...

Embodiment 12

[0054] Embodiment 12 (note numbering):

[0055] Raw material acceptance, storage in refrigerated storage (-18°C) and sensory inspection at delivery;

[0056] Refrigeration and thawing: Take duck blanks that have passed the sensory inspection at -18°C and place them in a refrigerator at 5°C for 15 hours;

[0057] Cleaning and Disinfection: Here, it is necessary to eviscerate and remove the glands from the refrigerated and thawed duck blanks, and soak and disinfect the duck blanks with an aqueous solution of sodium hypochlorite complex with a pH value of 5.0 at 200ppm (effective concentration of chloride ions) for 15 minutes, and then use Washing with clean water;

[0058] Refrigerated marinating: put the duck blank in a refrigerator at 5°C for 12 hours, and use 100g of salt for every 1000g of duck blank;

[0059] Blanching and disinfection: put the duck base obtained by refrigerating and marinating into boiling water, add 2% edible alcohol compound and 2% glycine compound int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com