Injection device, internal combustion engine, and method for operating an internal combustion engine

一种喷射装置、内燃机的技术,应用在燃料喷射装置、内燃活塞发动机、燃烧发动机等方向,能够解决高废气率、冷启动、启动困难等问题,达到冷启动性能改善的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the different views, the same parts are always indicated by the same reference numerals and are therefore usually named or stated respectively only once.

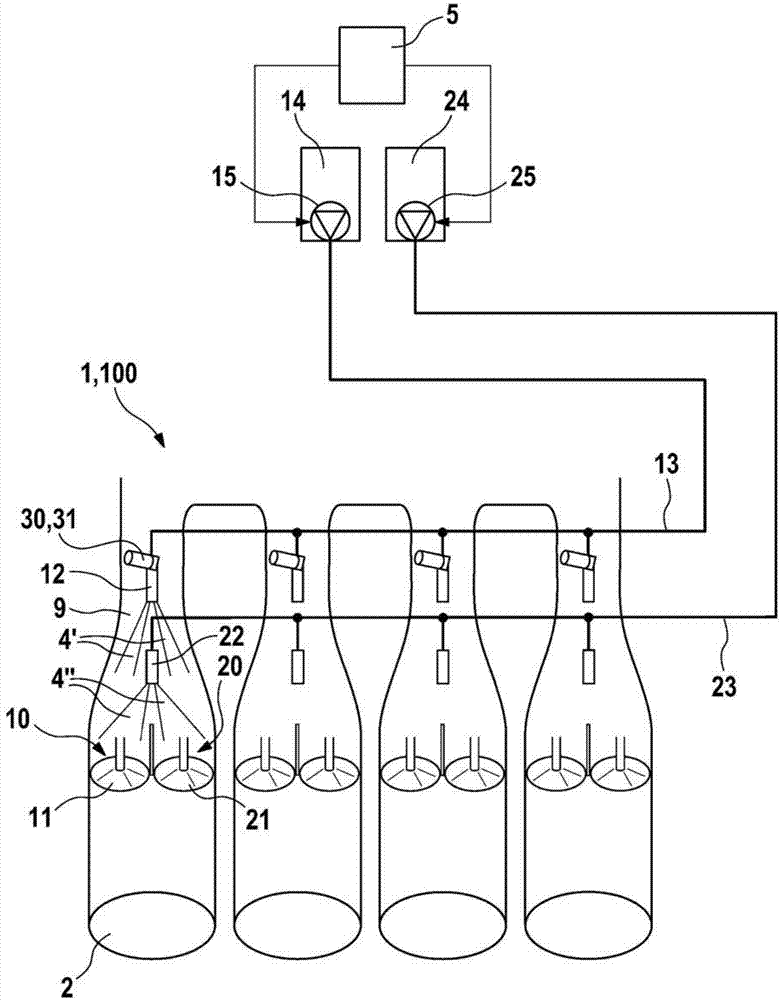

[0018] figure 1 A schematic diagram of an injection device 1 according to an exemplary embodiment of the invention and an internal combustion engine 100 at least partially is shown. The internal combustion engine 100 is depicted with, for example, four cylinders. Each of these four cylinders includes a combustion chamber 2 in which a piston, not shown, moves. The walls of each combustion chamber 2 respectively have a first inlet 10 and a second inlet 20 through which the air-fuel mixture is sucked into the combustion chamber 2 via a suction pipe 9 . Each combustion chamber also has an outlet, not shown, through which untreated exhaust gases of the burned air-fuel mixture exit the combustion chamber 2 . Each cylinder also has a first inlet valve 11 and a second inlet valve 21 , wherein the first inlet valve 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com