Process for forming an aramid copolymer

A technology of polymer and p-phenylenediamine, which is applied in the field of preparing aromatic polyamide polymers, and can solve problems such as control of the position of monomer components without

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

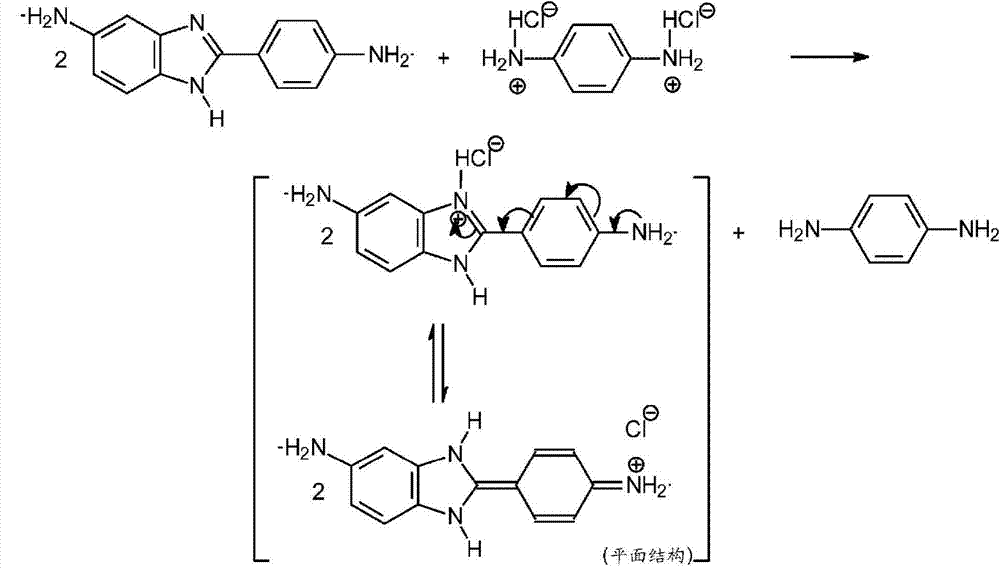

Method used

Image

Examples

example

[0063] NMP, DMAC, LiCl, CaCl 2 , DAPBI, PPD and TCl were obtained from commercial sources.

example 1

[0065] Add 83.71 g of NMP / CaCl to a 1 L reactor equipped with frame stirrer, nitrogen inlet / outlet 2 Premix (8.3% by weight (salt weight / total weight of salt and solvent)), 161.65 grams of NMP (N-methyl-2-pyrrolidone], 12.282 grams (0.055 moles) of DAPBI (5(6)-amino-2 - (p-aminophenyl)benzimidazole), 4.250 g (0.023 mol) of PPD.2HCl (p-phenylenediamine dihydrochloride), and stirred at room temperature. Unlike the case of adding PPD, all solid materials Dissolve completely within 30 minutes under stirring. The clear solution is light blue. The reaction mixture is stirred and cooled to below 10° C. in an ice-water bath. At this point, 5.560 grams (0.027 moles) of TCl are added in one go and stirred under nitrogen 5 minutes. The ice water bath was removed and a second portion of TCl, 10.325 grams, was added in one portion and stirred slowly for 30 seconds, and then the stirrer speed was increased to maximum. The solution became very viscous, gelled, and eventually rubberized The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com