Method and structure for controlling via hole impedance of PCB board

A technology of PCB board and impedance control, which is applied in the field of communication to achieve high precision and improve the effect of signal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

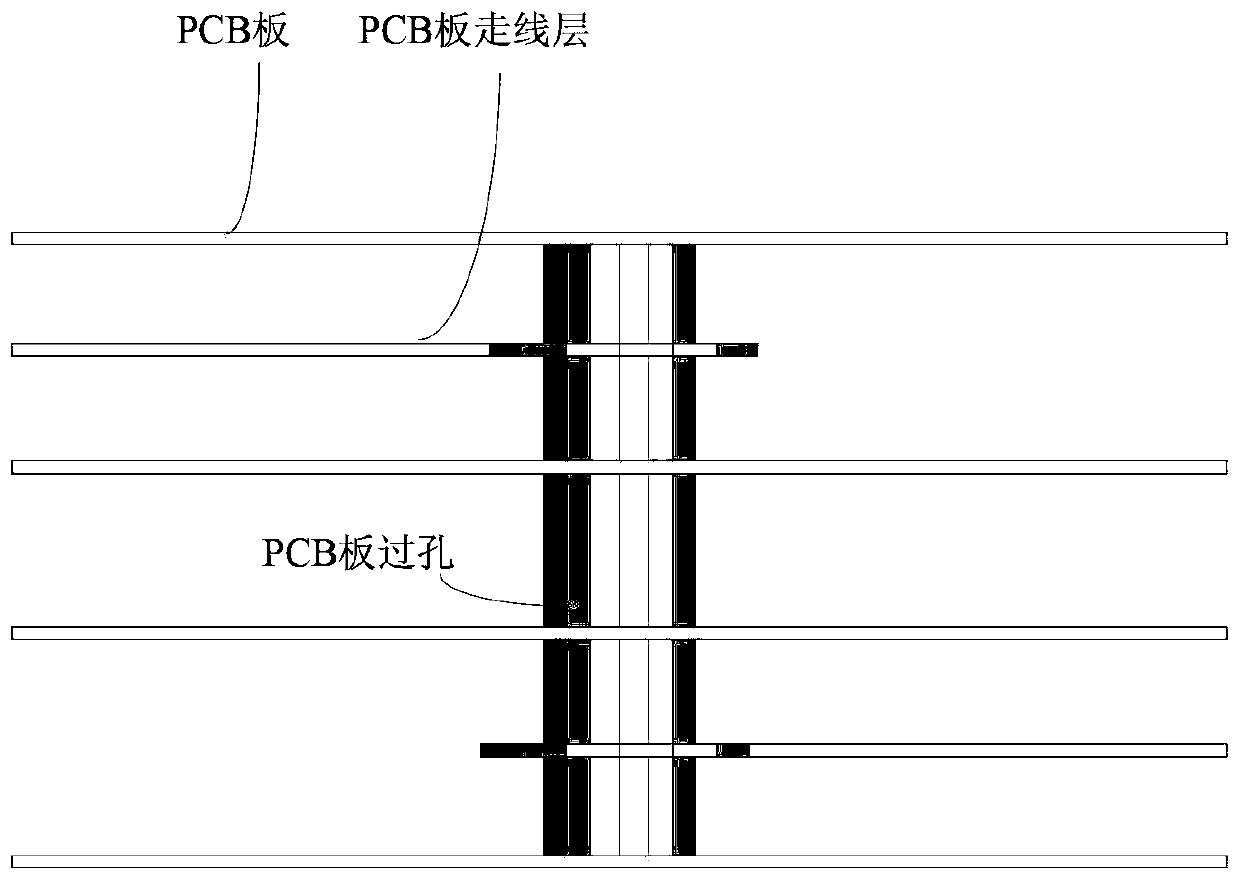

[0024] still with figure 2 Take the PCB board shown as an example, the production of signal vias on the PCB board generally includes the following control indicators:

[0025] 1. Drill Diamater

[0026] 2. Plating thickness (Plated)

[0027] 3. Regular Pad

[0028] 4. Thermal Relief

[0029] 5. Anti Pad (Anti Pad)

[0030] Among them, ordinary pads are mainly used in the outgoing layer and surface layer of the PCB board. The ordinary pads in the outgoing layer can enhance the mechanical connection performance between PCB traces and metal vias, which is beneficial to PCB mechanical processing. The ordinary pads of other layers except the surface layer and the outgoing layer are called non-functional pads. According to the signal integrity theory, the non-functional pad acts as the stub of the communication link, which will affect the effective transmission of the signal. The standard practice in the industry for many years is to delete the non-functional pads between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com