A method for automatic error correction and correction of resistive touch screen

A technology of automatic error correction and correction method, which is applied in the direction of electrical digital data processing, instruments, and data processing input/output process, etc. The finished machine cannot be recalibrated and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

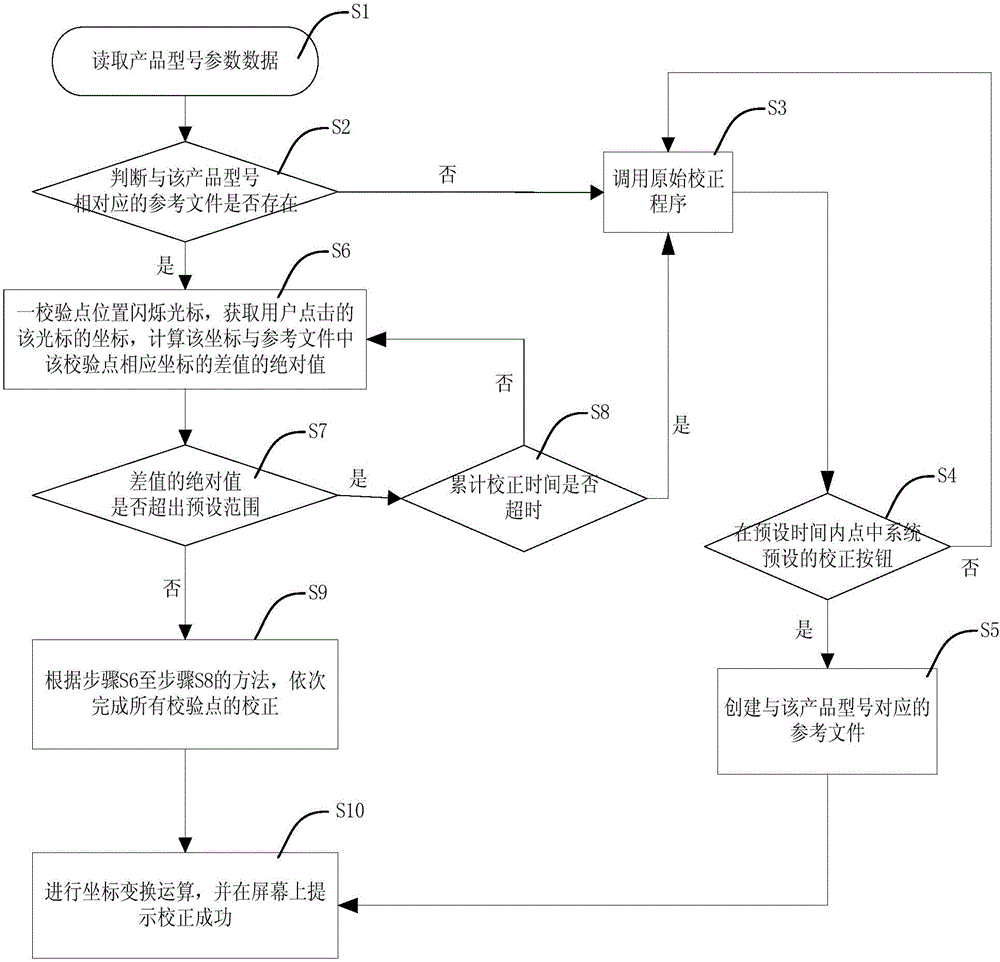

[0019] The invention discloses an automatic error correction correction method for a resistive touch screen, such as figure 1 As shown, the method includes the following steps:

[0020] Step S1, read product model parameter data;

[0021] Step S2, judging whether the reference file corresponding to the product model exists, if not, then execute step S3, if yes, then execute step S6;

[0022] Step S3, call the original correction program, and then execute step S4. In this step S3, the original correction procedure includes: step S30, obtain the coordinates of the upper left corner, the upper right corner, the lower right corner, the lower left corner and the coordinates of the center point in the system; step S31, display the cursor at the check point on the screen in turn , and the user is prompted to click the cursor; step S32, the user click...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com