Automatic adjusting jig for focusing of fixed-focus lens and adjusting method of automatic adjusting jig

A fixed-focus lens and automatic adjustment technology, applied in focusing devices, color TV parts, TV system parts, etc., can solve problems such as unstable production efficiency and yield, difficult to control precision, and stiff finger joints. Improve production efficiency, reduce workload and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

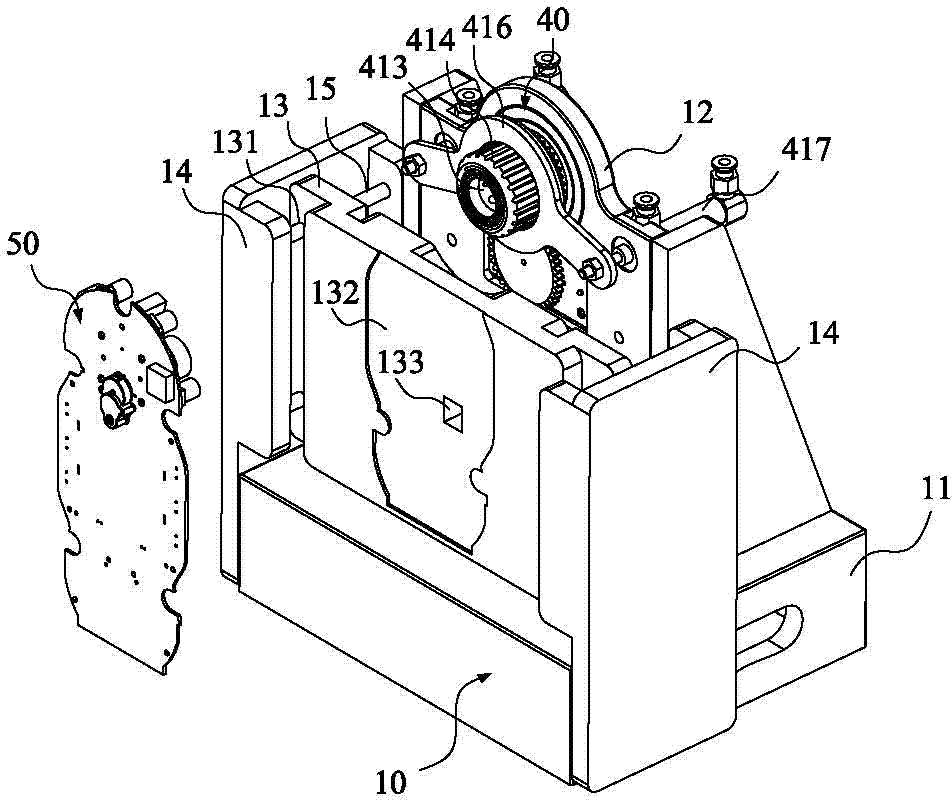

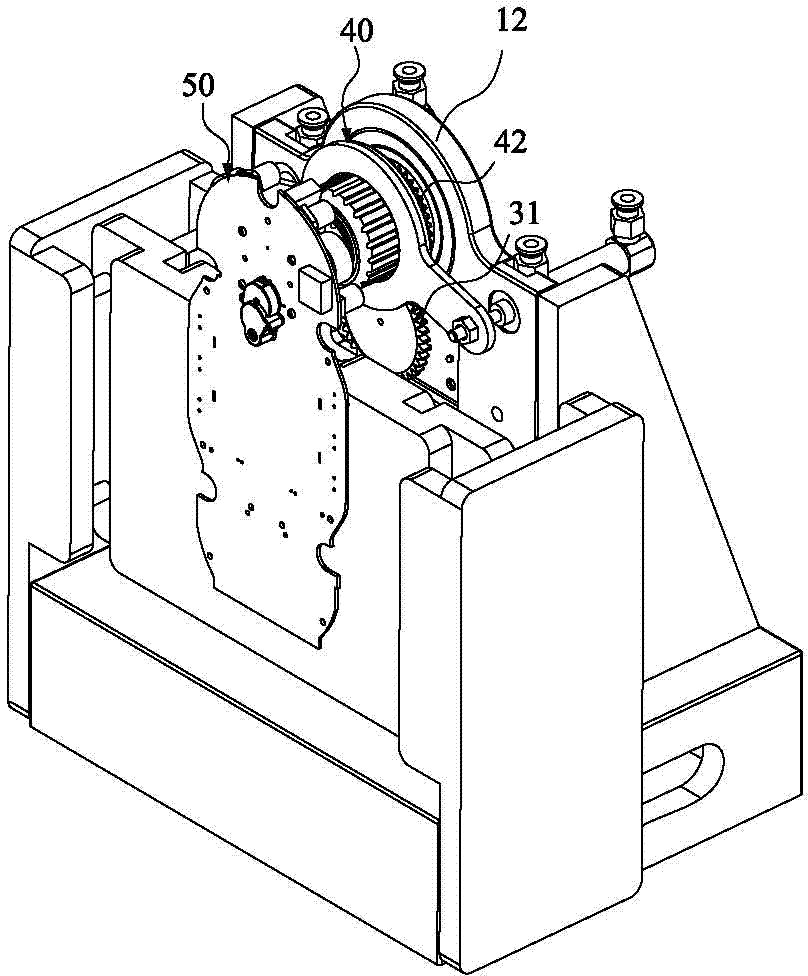

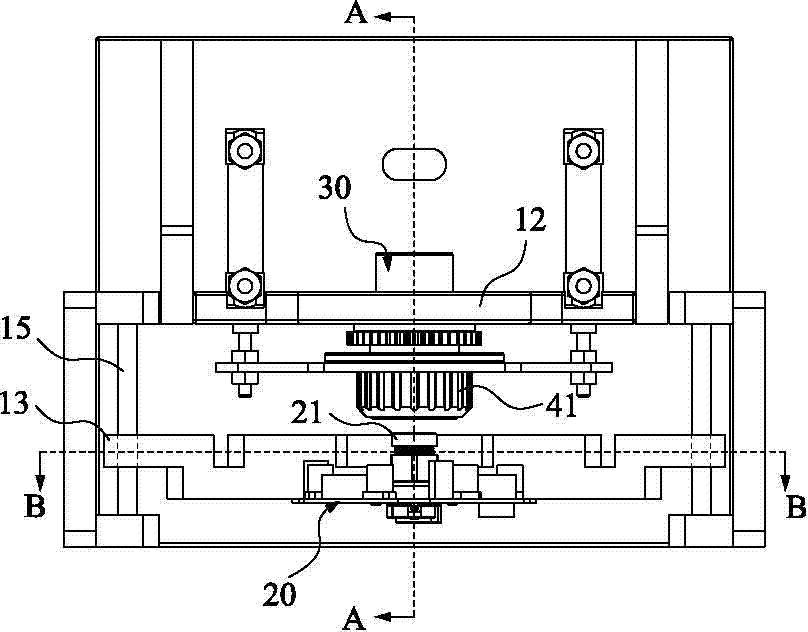

[0044] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the preferred embodiment of the present invention, the adjustment jig of the auto-focus fixed-focus lens can automatically focus on the camera-type fixed-focus lens 51 . It includes a base 10, a control device 20, a driving device 30 and a rotating device 40, wherein:

[0045] Such as figure 1 As shown, the base 10 includes a base 11 , a fixed plate 12 , a movable plate 13 and two support frames 14 , the fixed plate 12 is fixed on the base 11 , and the rotating device 40 and the driving device 30 are fixed on the fixed plate 12 . The two support frames 14 are arranged at intervals and fixed on the base 11 beside the fixed plate 12. Guide rods 15 are horizontally arranged on the two support frames 14. The moving plate 13 and the fixed plate 12 are arranged parallel to each other, and during the autofocus process The relative guide rod 15 moves to adjust the distance with the fixed plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com