Characterization and detection method of native-surface laser paper color characteristics

A color characteristic and detection method technology, applied in the direction of color/spectral characteristic measurement, etc., can solve problems such as high equipment requirements, difficulty in ensuring detection stability, and complicated detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

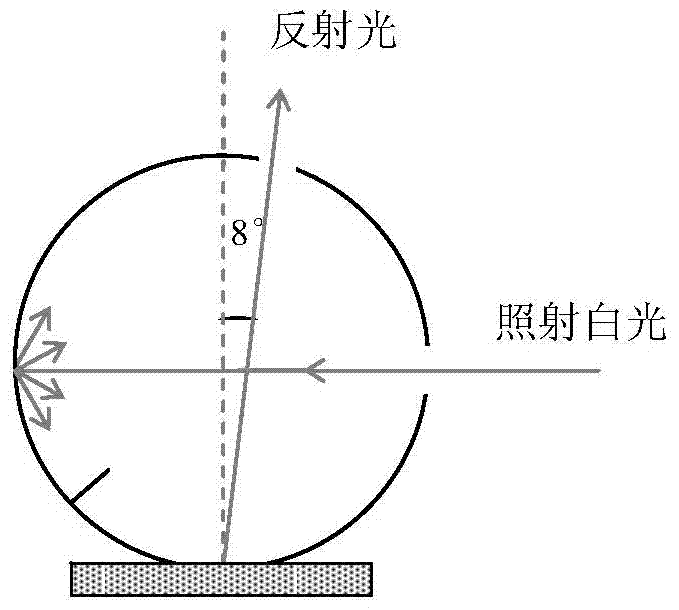

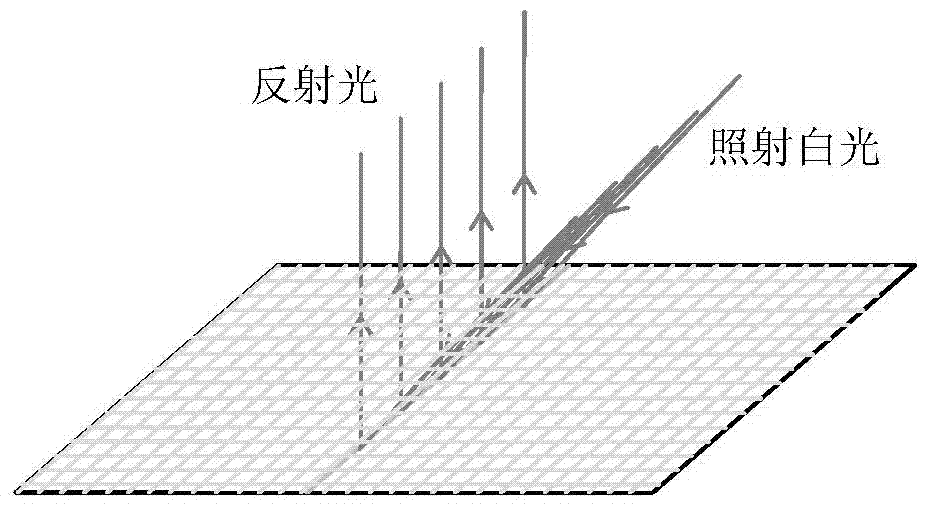

[0044] The implementation test process and analysis are described below in conjunction with the accompanying drawings and examples to further illustrate the present invention, but they cannot be used to limit the scope of the present invention.

[0045] In product quality control, there are often standard samples and test samples. The standard sample is the reference standard for the enterprise as a quality standard, and the test sample is the product in production.

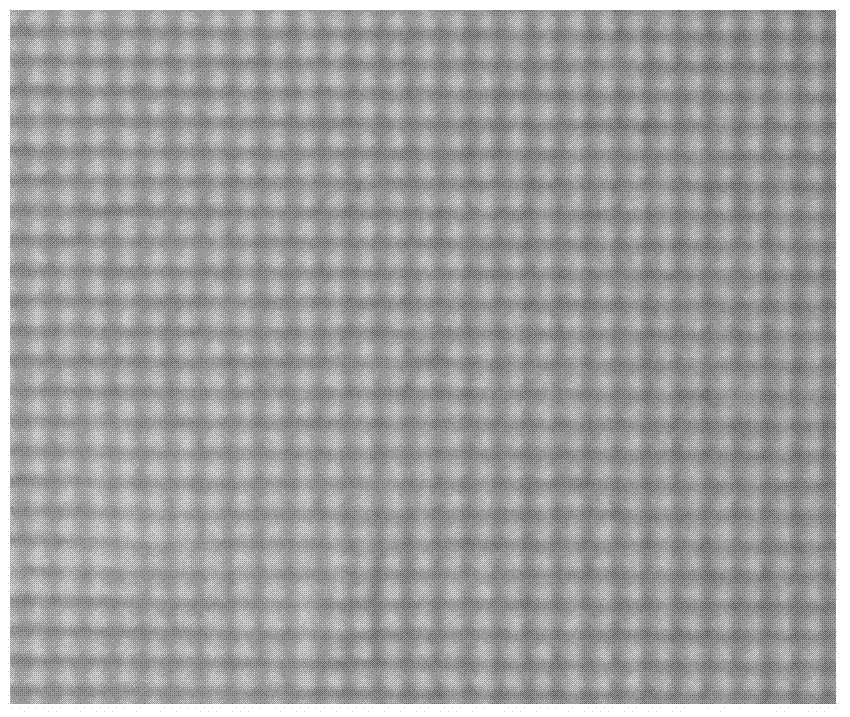

[0046] Embodiment Take the plain gold laser standard sample of 20mm * 20mm (called the gold standard sample) and the detection sample (called the gold comparison sample) respectively; and the plain silver laser standard sample of 20mm * 20mm (called the silver standard sample) ) and two test samples (called silver samples). The square grating structure of the two types of laser paper is as follows: image 3 As shown, the bright part is the part of the exposed substrate, the dark part is the part of the grating m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diffraction angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com