Airtight test device for tube bundles for heat exchangers

A technology of heat exchanger and airtight test, which is applied in the direction of heat exchanger sealing device, heat exchange equipment, heat exchanger type, etc., which can solve the problems of poor economy, large workload, high test cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

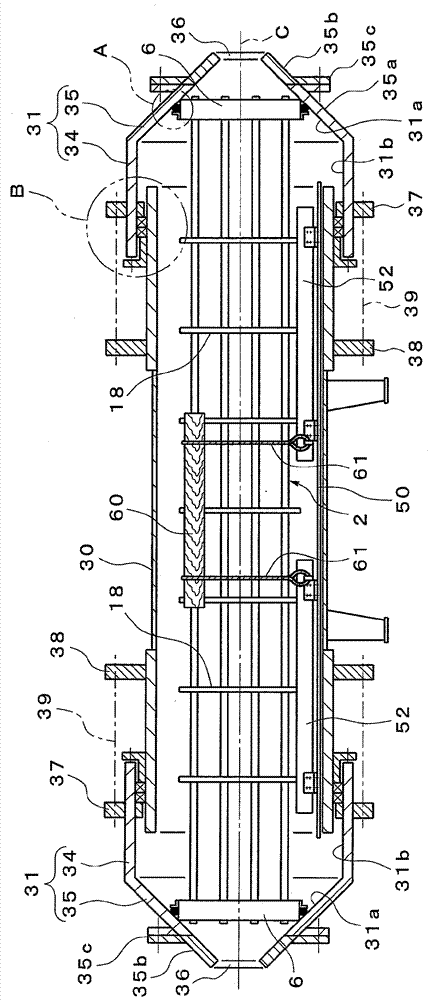

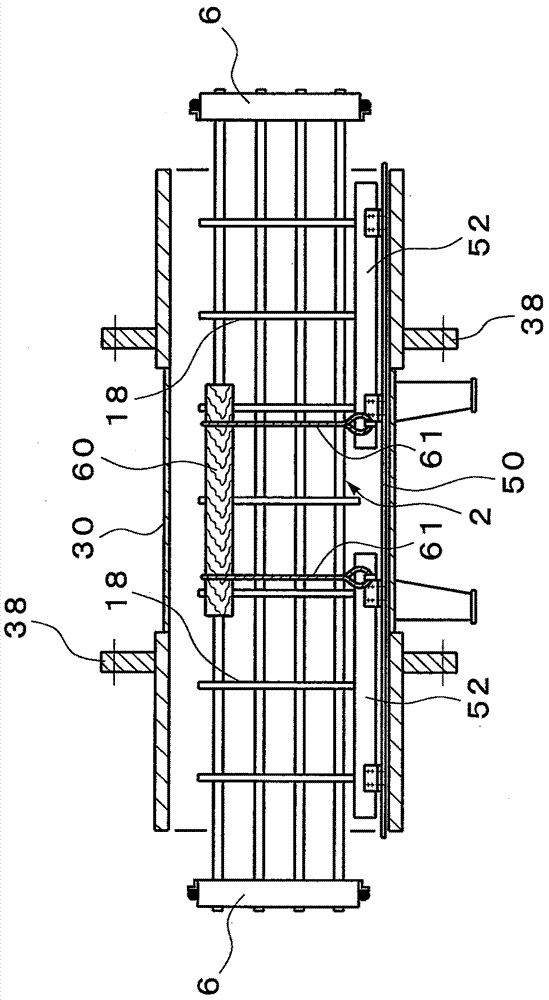

[0037] Figure 1 to Figure 8 Indicates that the airtight test device related to the tube bundle of the present invention is used to carry out Figure 10 A diagram of an embodiment of the airtight test of the tube bundle 2 of the floating head heat exchanger shown, with regard to the structure of the tube bundle 2, and Figure 10 The shown configurations are the same, so the descriptions thereof will be simplified by giving the same reference numerals below.

[0038] First, if Figure 1 to Figure 5 As shown, the airtight test device consists of a cylindrical main body 30, sealing covers 31 respectively arranged at the openings at both ends of the main body 30, the inner surface 31a of the sealing cover 31 and the tube sheet 6 of the tube bundle 2. The O-ring (first sealing member) 32 that airtightly seals between the outer circumference of the body, and the packing gland (second seal) that airtightly seals between the inner surface 31b of the sealing cover 31 and the outer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com