Variable-diameter single-screw-shaft dehydrating device

A single-screw, squeeze dryer technology, applied in the direction of drying, drying solid materials, drying solid materials without heating, etc., can solve the problems that the moisture content of materials cannot be effectively reduced, the compression ratio of the squeeze dryer is small, and the production cost is reduced. , to achieve the effect of unobstructed water outlet, improved extrusion effect and reduced moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

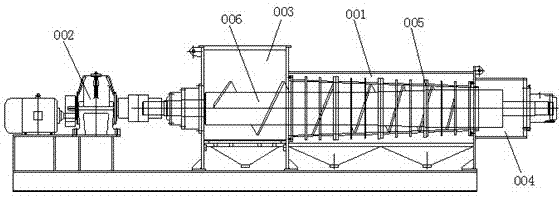

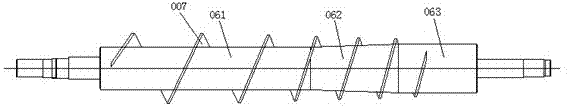

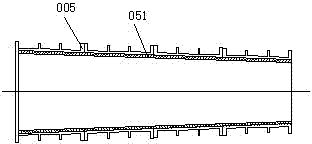

[0016] A variable-diameter single-screw shaft squeezer, comprising a frame 001, a driving device 002, a feed assembly 003 and a discharge assembly 004 arranged at both ends of the frame 001, a conical screen cage 005 arranged in the frame 001, and The driving rotating shaft 006 installed in the screen cage 005 and coaxially arranged, one end of the driving rotating shaft 006 is connected with the driving device 002, and the driving rotating shaft 006 is provided with a spiral blade 007, and the diameter of the spiral blade 007 varies with the diameter of the cone. The inner diameter of the shaped screen cage 005 gradually becomes smaller, and it is characterized in that the diameter of the driving rotating shaft 006 gradually increases with the reduction of the inner diameter of the screen cage 005, and the pitch of the spiral blade 007 gradually shortens with the increasing diameter of the driving rotating shaft 006. A layer of screen 051 is installed on the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com