Double-cone-ring type continuously variable transmission

A technology of continuously variable transmission and continuously variable transmission device, which is applied in the direction of vehicle gearboxes, friction transmission devices, transmission components, etc., can solve the problems that are difficult to satisfy the power and economy of the whole vehicle at the same time, and achieve a wide range of transmission ratio coverage , light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

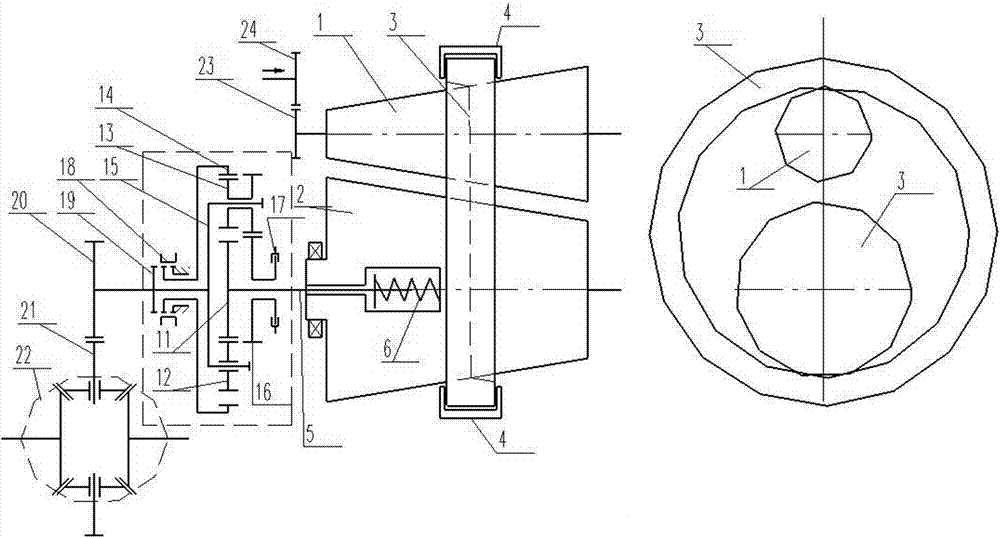

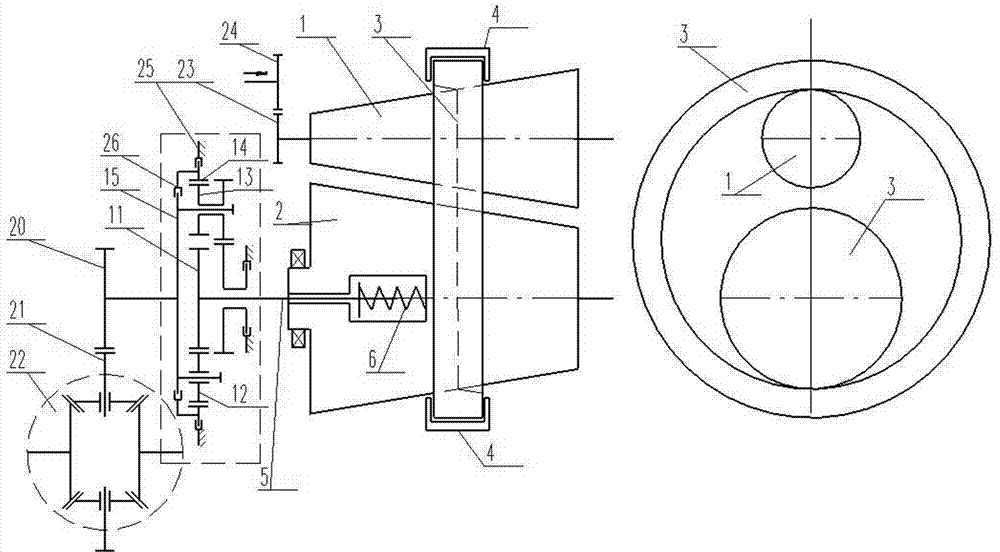

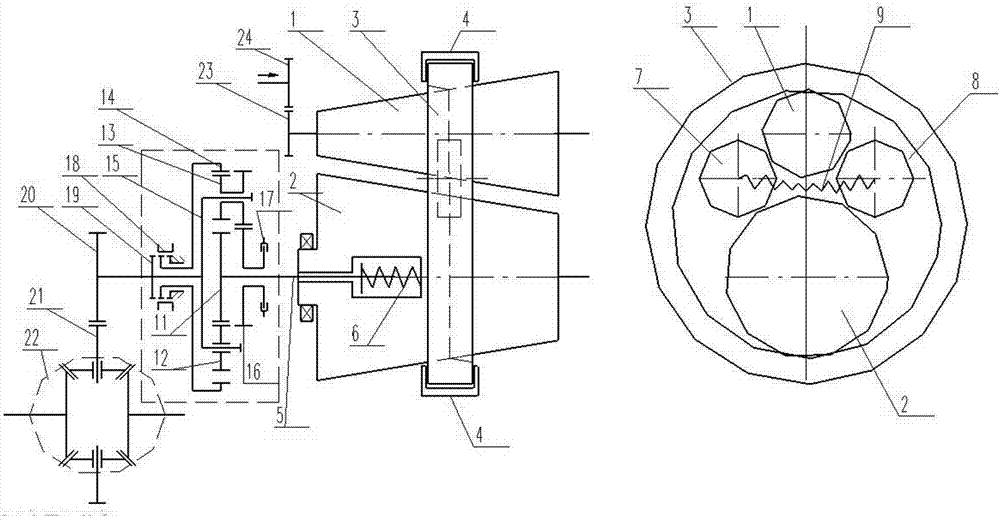

[0021] In the figure, the square dashed box is a schematic diagram of a planetary row structure speed change device, and the circle dashed box is a schematic diagram of the differential. The double-cone ring continuously variable transmission device is composed of input and input cone 1, output shaft 2, ring 3, speed regulating device 4 and spring 6, etc. The main reducer is composed of the main reducer small tooth 20 and the main reducer large tooth 21 . There is a pair of reversing gears (gear 23 and gear 24 ) between the power input end and the input input cone 1 . When the power rotation direction of the power source changes, the pair of reversing gears can be cancelled.

[0022] figure 1 The embodiment shown is a double-planetary row parallel shaft with mutually inverted cone and double cone ring type continuously variable transmission. The axes of the input cone 1 and the output cone 2 are parallel to each other, and are installed upside down to each other, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com