Design principle and manufacturing method of porous material having dynamic adsorption and transfer functions

A technology of porous materials and transfer function, applied in the field of porous materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] The fabric in this embodiment is woven by knitting single-side weft knitting technology.

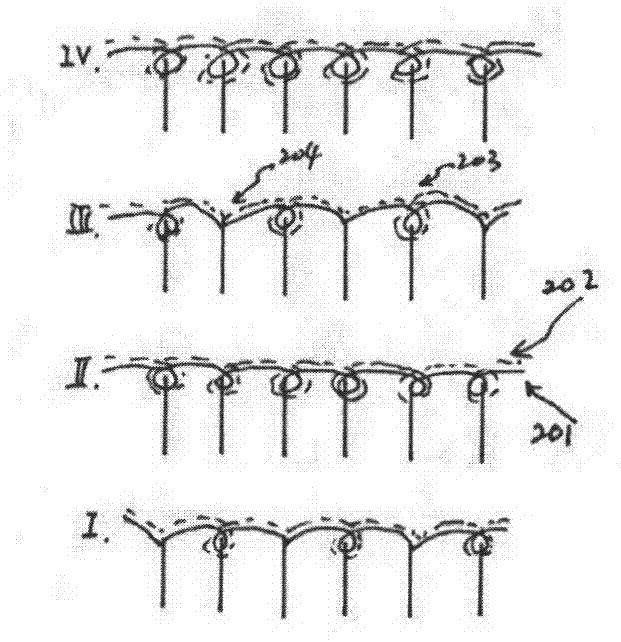

[0029] The fabric structure is a 4-way weaving cycle, and its weaving diagram is as follows figure 2 . The first way: Hydrophobic yarn is tuck-knitted on odd-numbered knitting needles (1, 3,) and tuck-knitted on even-numbered knitting needles (2, 4,). and covered with hydrophobic yarn. The second way: the hydrophilic yarn is woven in a circle on all knitting needles, and the elastic yarn is woven in a circle on all knitting needles at the same time in a single-sided plating method, and is covered by the hydrophilic yarn. The third way: Weave the hydrophobic yarn in a loop on the odd-numbered knitting needles (1, 3,) and weave the hydrophobic yarn in a tuck on the even-numbered knitting needles (2, 4,). and covered with hydrophobic yarn. The fourth way: the weaving method of hydrophilic yarn and elastic yarn is the same as the second way.

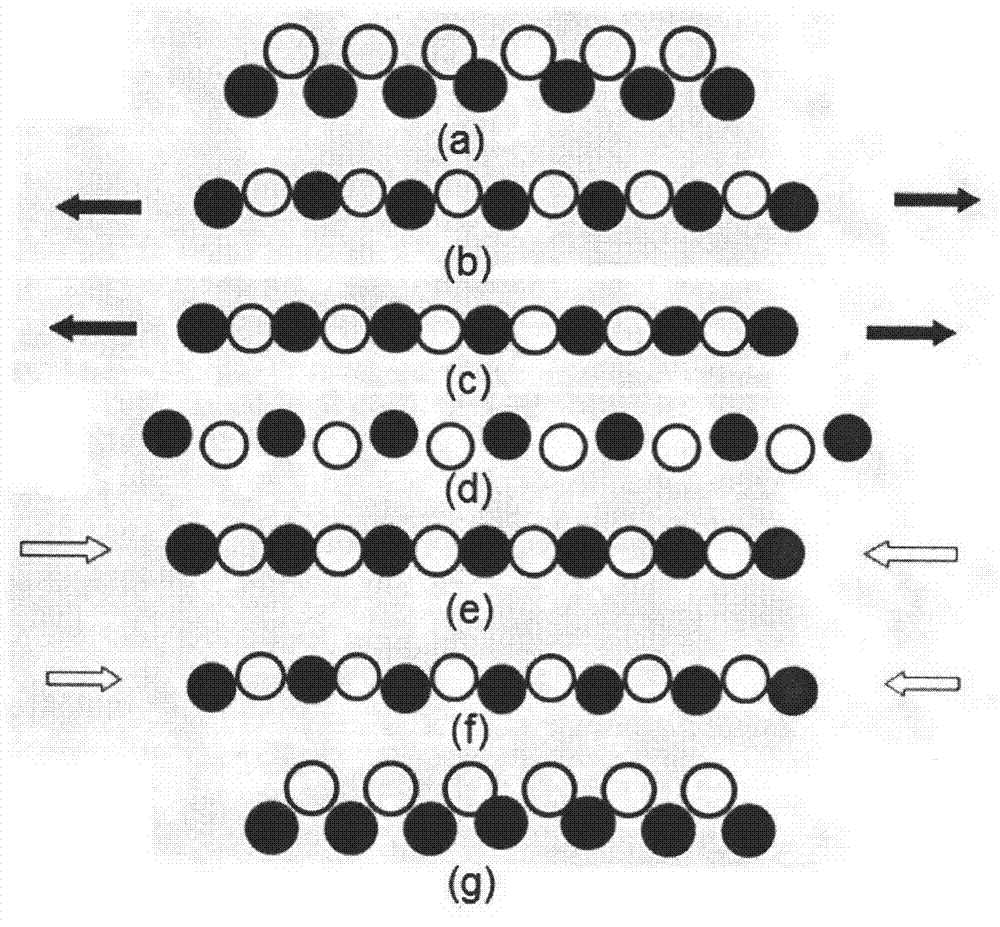

[0030] In the weaving cycle, both h...

example 2

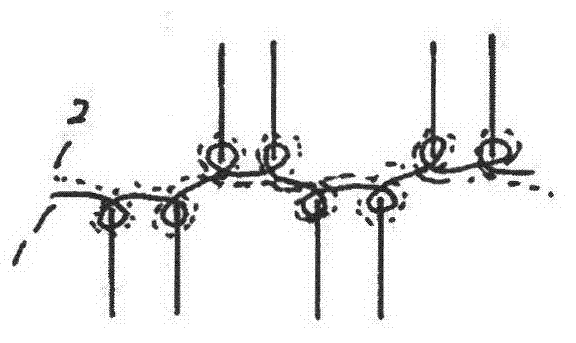

[0033] The fabric in this embodiment is woven by knitting double-sided weft knitting technology ( image 3 ).

[0034] The fabric structure is a double-sided plating structure fabric, and its weaving diagram is shown in the figure. The hydrophobic yarn 1 and the hydrophilic yarn 2 are fed into the same knitting system in the way of plating, so that the yarn 1 covers the yarn 2 when the cylinder knitting needles and dial knitting needles form a loop.

[0035] When the fabric is static, both sides of the fabric are loops of hydrophobic yarns, and when stretched, both sides of the fabric are changed into loops formed by hydrophobic yarns and hydrophilic yarns, which are separated by vertical strips.

example 3

[0037] The fabric in the present embodiment is woven by knitting warp knitting technology ( Figure 4 ).

[0038] The fabric has a 4-comb structure

[0039] GB4 (back comb) is elastic yarn, full wear; GB3 is hydrophobic yarn, full wear; GB2, GB1 are hydrophilic yarns, GB2 2 wear 2 empty, GB13 empty 2 wear 1 empty. The motion diagram of the yarn lapping of the fabric is shown in the figure, and the number of lapping yarns is as follows:

[0040] GB1: 3-2 / 2-3 / 2-1 / 1-2 / 1-0 / 0-1 / 1-2 / 2-1 / 2-3 / 3-2 / 3-4 / 4-3 / 4-5 / 5-4 / 4-3 / 3-4 / /

[0041] GB2: 2-3 / 3-2 / 3-4 / 4-3 / 4-5 / 5-4 / 4-3 / 3-4 / 3-2 / 2-3 / 2-1 / 1-2 / 1-0 / 0-1 / 1-2 / 2-1 / /

[0042] GB3: 1-0 / 1-2 / /

[0043] GB$: 3-4 / 1-0 / /

[0044]In order to confirm the dynamic adsorption and transfer function of the porous material of the present invention, a dynamic moisture content test (MMT tester) was performed on the fabric of Example 1. The fabric is woven by 70D Tactel, 70D p.p and 40DLycra. Figure 5 It is the moisture content of the technical reverse side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com