Engine oil recovery and pretreatment device of vertical retired passenger car

A pretreatment device and technology for passenger cars, applied in the direction of lubricating compositions, etc., can solve the problems of waste engine oil detection and graded recovery pretreatment devices and methods, etc., achieve remarkable filtration and recovery effects, high feasibility, strong systemic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

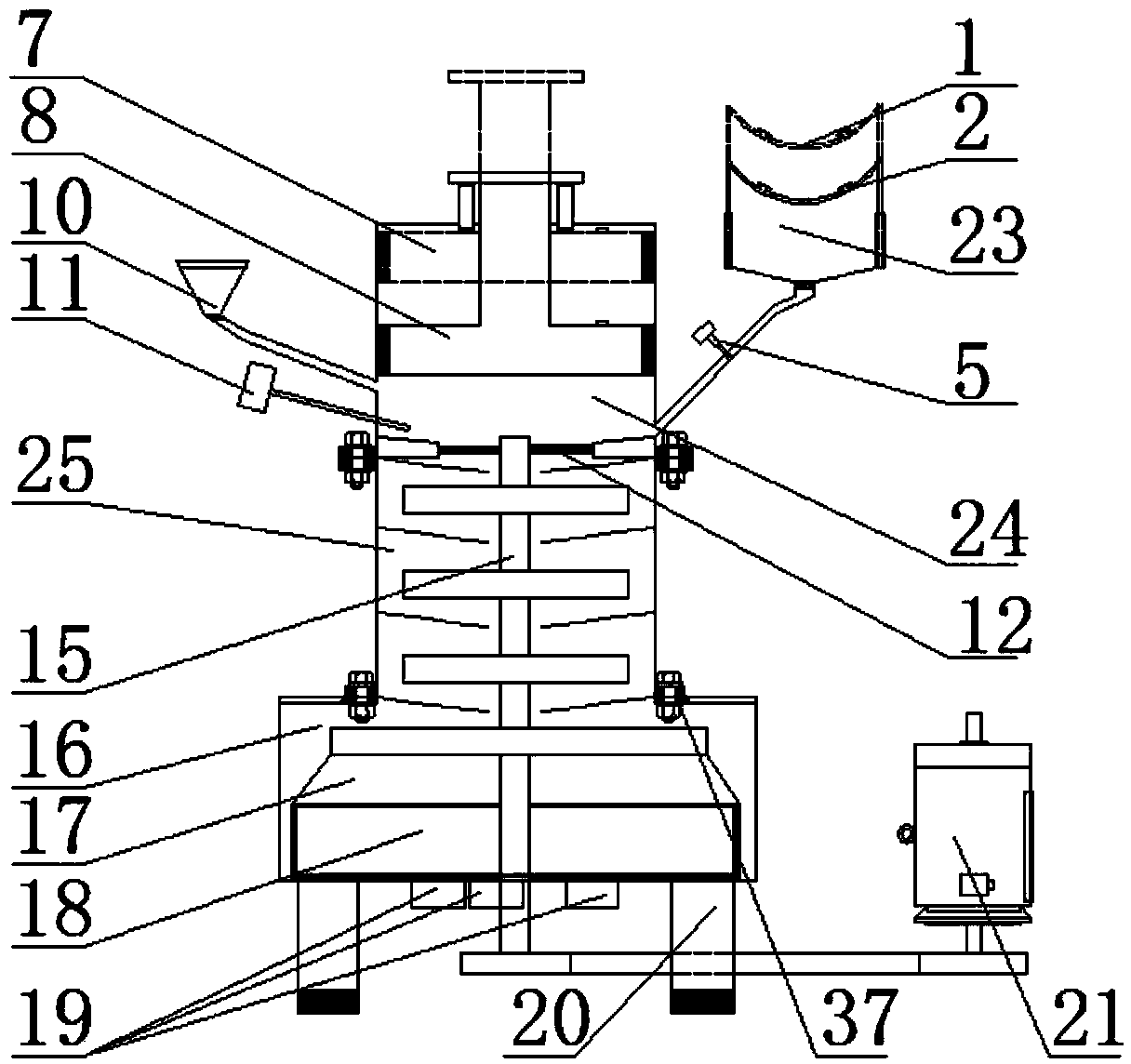

[0041] In order to better understand the present invention, the content of the present invention will be further clarified below in conjunction with specific embodiments and accompanying drawings, but the content of the present invention is not limited to the following embodiments.

[0042] The invention provides a three-dimensional decommissioned passenger car engine oil recovery pretreatment device, which includes: a physical and chemical performance detection unit, a wear particle analysis and filtration unit, and a classification recovery unit.

[0043] The physical and chemical performance detection unit is composed of a waste engine oil pre-storage tank 23 and a waste engine oil dilution cylinder 24 connected to the waste engine oil pre-storage tank through a conduit 6. The waste engine oil dilution cylinder 24 is located at the upper end of the wear particle analysis and filtration cylinder 25 ( see figure 2 ).

[0044] Since different types of decommissioned passenge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com