Equipment and method for preparing chlorosilane from silane through reverse disproportionation

A technology of anti-disproportionation and chlorosilane, which is applied in the field of silane anti-disproportionation to prepare chlorosilane, which can solve the problems of safety and hidden dangers of silane, and achieve the effects of reducing risk, improving utilization rate and reducing total investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] Take a polysilicon enterprise with an annual output of 4000t and an annual production time of 8000h as an example.

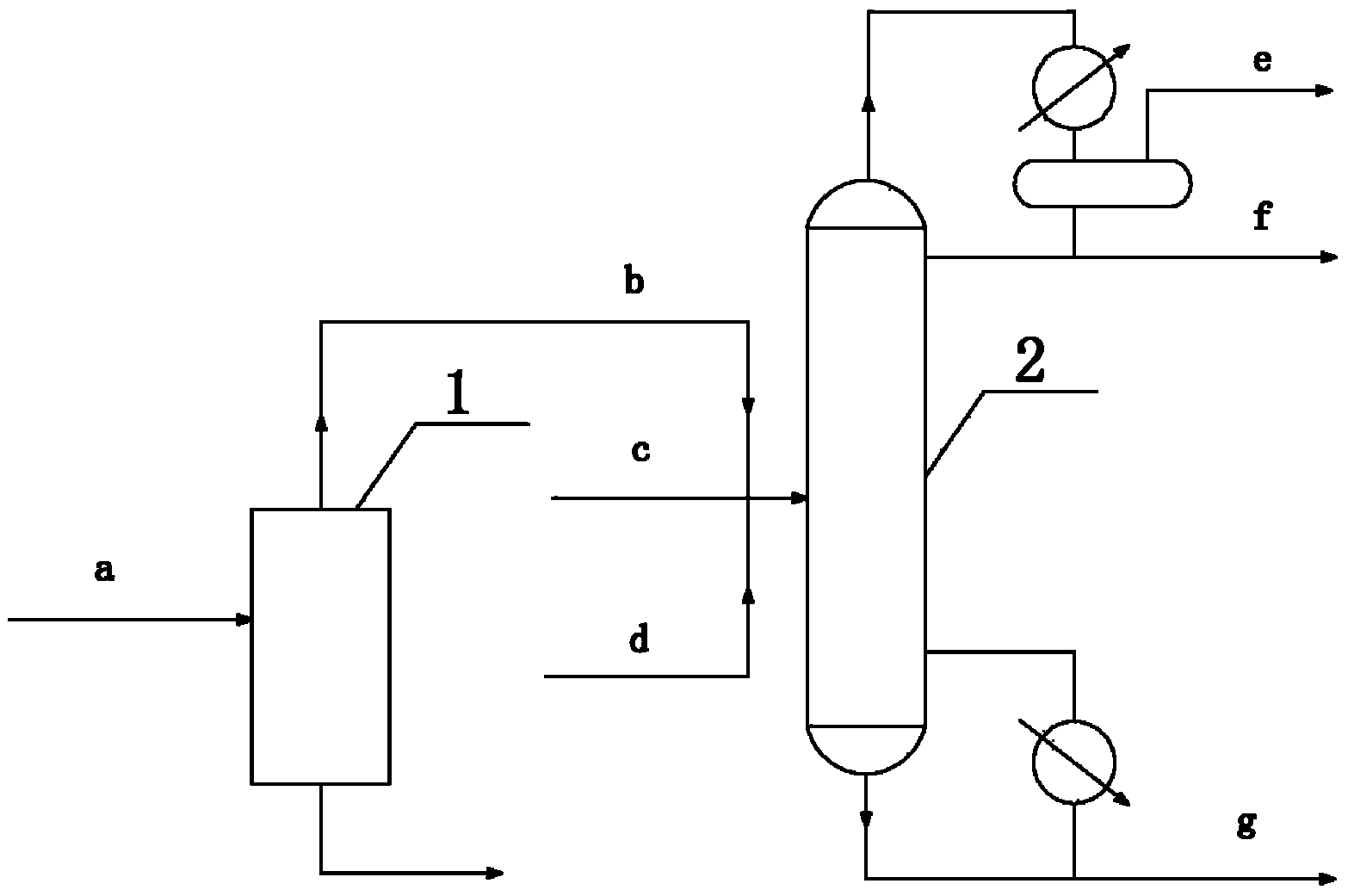

[0031] High-purity polysilicon is produced by using high-purity silane and hydrogen as raw materials. The feed rate of high-purity silane and hydrogen is 0.5t / h, and it directly enters the reduction furnace (1) to prepare high-purity polysilicon; the undecomposed polysilicon in the polysilicon reduction furnace (1) Silane and hydrogen are introduced into the anti-disproportionation rectification tower (2), and the anti-disproportionation rectification tower has 30 theoretical plates.

[0032] After mixing silane with dichlorodihydrosilane and silicon tetrachloride, it is fed from the 16th theoretical plate of the catalytic rectification tower. The feed molar ratio of each substance is 10:0.1:0.2 (silicon tetrachloride: dichlorodihydrosilane: silane). The reaction position is the 15th theoretical plate of the anti-disproportionation distillation column. ...

example 2

[0034] Take a polysilicon enterprise with an annual output of 5000t and an annual production time of 8000h as an example.

[0035] High-purity polysilicon is produced by using high-purity silane and hydrogen as raw materials. The feed rate of high-purity silane and hydrogen is 0.6t / h, which directly enters the reduction furnace (1) to prepare high-purity polysilicon; the undecomposed polysilicon in the polysilicon reduction furnace (1) Silane and hydrogen are introduced into the anti-disproportionation rectification tower (2), and the anti-disproportionation rectification tower has 1000 theoretical plates.

[0036] Silane, trichlorosilane and silicon tetrachloride are fed separately. Silicon tetrachloride is fed from the top position of the catalytic rectification tower, and trichlorosilane and silane are fed from the 16th theoretical plate of the catalytic rectification tower. The feed molar ratio of each substance is 1000:5:1 (silicon tetrachloride: trichlorosilane: silane)...

example 3

[0038] Take a polysilicon enterprise with an annual output of 1000t and an annual production time of 8000h as an example.

[0039]High-purity polysilicon is produced by using high-purity silane and hydrogen as raw materials. The feed rate of high-purity silane and hydrogen is 0.1t / h, and it directly enters the reduction furnace (1) to prepare high-purity polysilicon; the undecomposed polysilicon in the polysilicon reduction furnace (1) Silane and hydrogen are introduced into the anti-disproportionation rectification tower (2), and the anti-disproportionation rectification tower has 5 theoretical plates.

[0040] Silane is mixed with trichlorosilane and silicon tetrachloride and then fed from the third theoretical plate of the catalytic rectification tower. The feed molar ratio of each substance is 3:0.1:1 (silicon tetrachloride: trichlorosilane: silane). The reaction position is the second theoretical plate of the anti-disproportionation distillation column. The reaction tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com