Air cylinder special for pneumatic compression type oil vapor recovery sealing device of train

A technology of pneumatic pressing and sealing device, which is applied in distribution device, special distribution device, liquid distribution, conveying or transferring device, etc., can solve the problems of insufficient pressing force, insufficient rigidity, insufficient pressing force of sealing device and sealing requirements, etc. , to achieve stable and reliable locking force, reduce overall weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

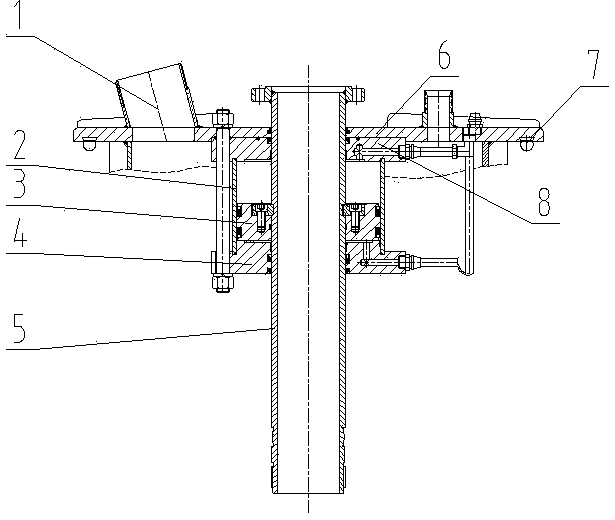

[0009] A special cylinder for a train pneumatic compression type oil and gas recovery sealing device, including a medium flow pipe 5 and a sealing cover 6 matched with the tank opening on the top of the train tank car. The groove is equipped with a rubber gasket 7, and the rubber gasket 7 is provided with a harder dovetail connection part matched with the above-mentioned dovetail groove, in order to connect firmly; a softer sealing part is provided below the dovetail connection part, which can Compensate the flatness error of the tank mouth during sealing to improve the sealing performance; there is an installation hole in the middle of the sealing cover 6 through which the medium flow pipe passes, and an oil and gas recovery port 1 is provided on the sealing cover next to the installation hole, and a The cylinder body 2 is set outside the medium flow pipe 5, the oil and gas recovery port 1 is set on the sealing cover 6 outside the cylinder body 2, and the two ends of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com