Movable cantilever hoisting device

A lifting device and mobile technology, applied in the direction of portable lifting device, hoisting device, etc., can solve the problems of human health damage, high labor intensity, low efficiency, etc. The effect of restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

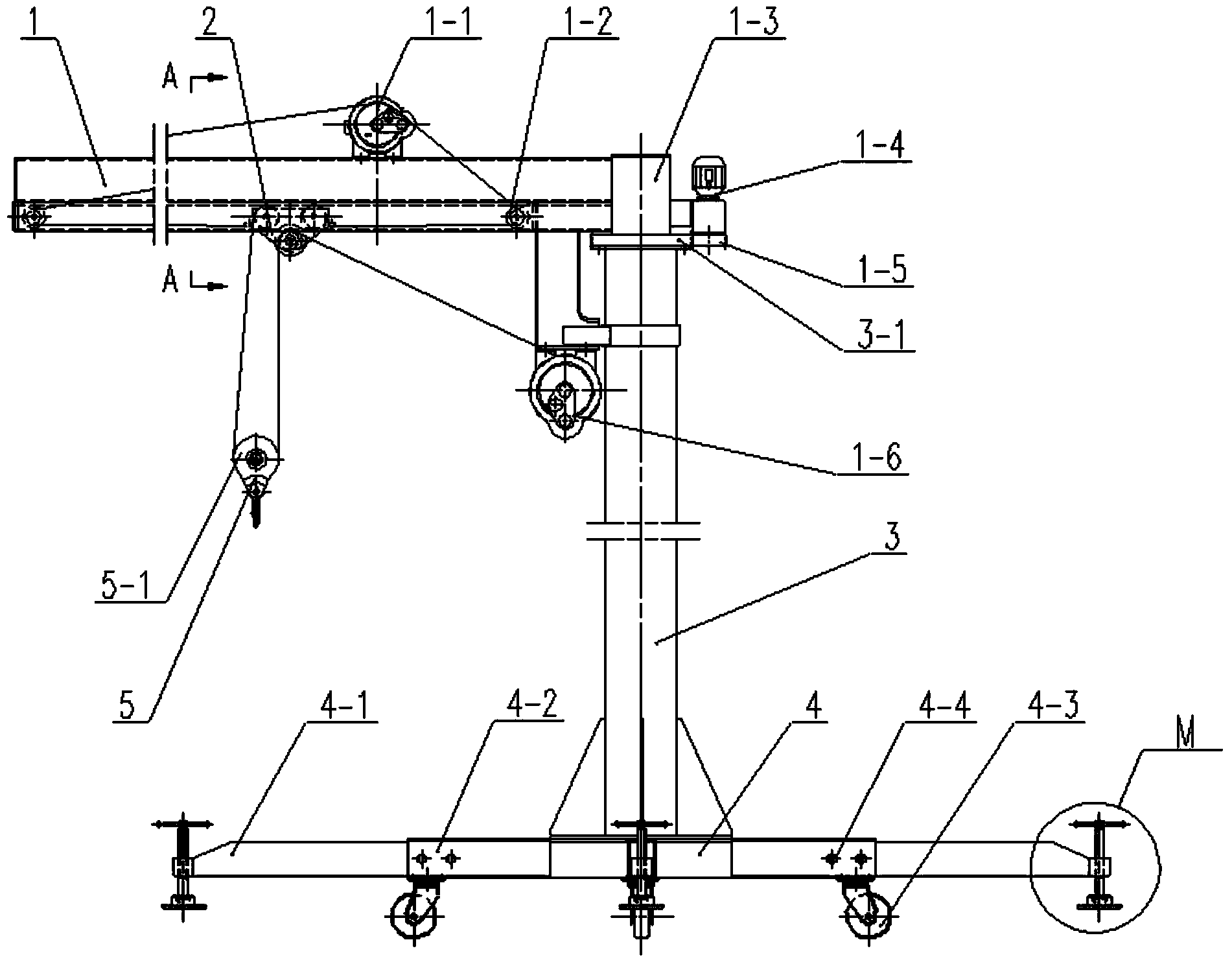

[0024] The overall structure of the embodiment of the mobile cantilever lifting device is as follows: figure 1 Shown is a self-propelled jib hoist equipped with feet.

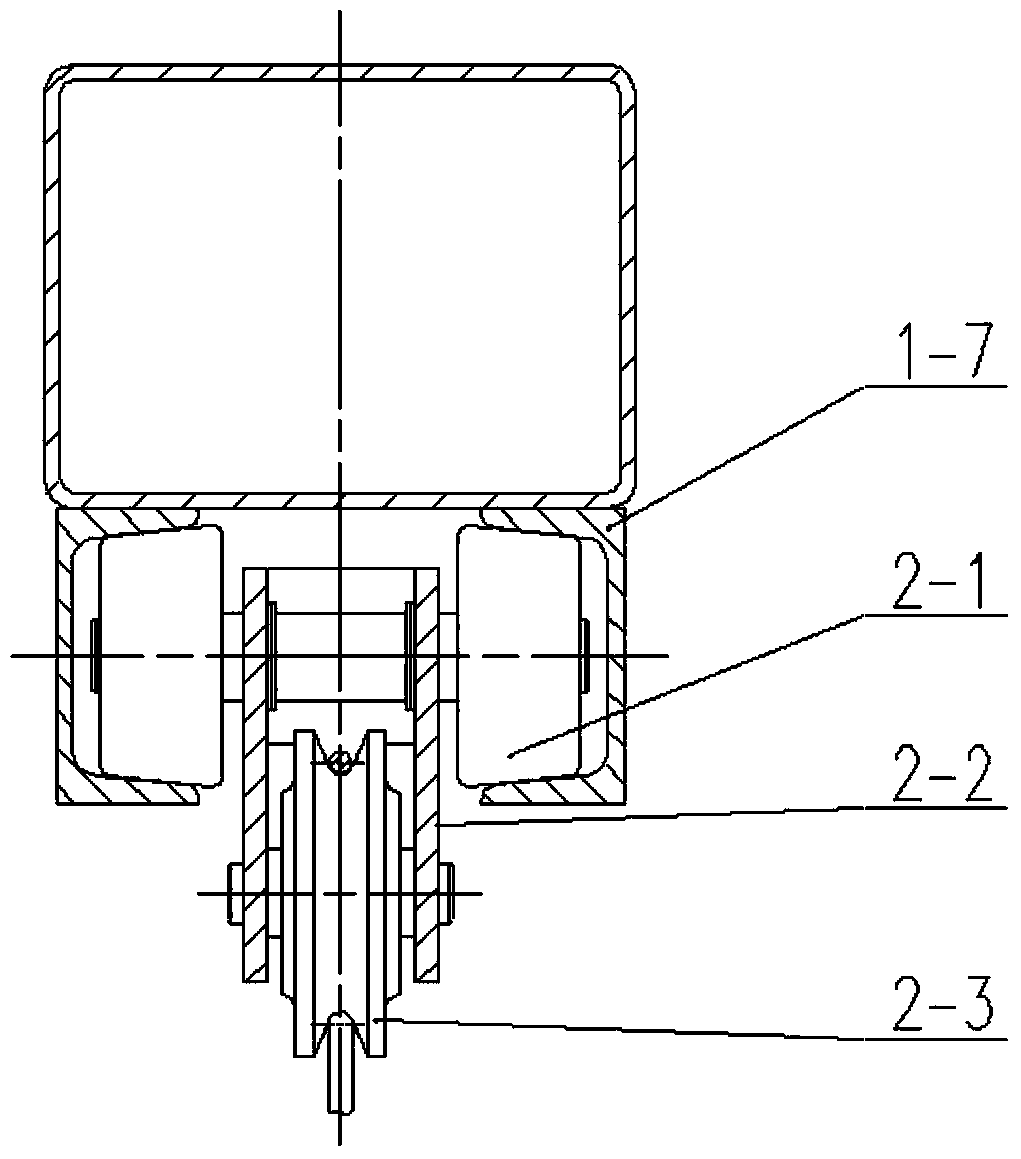

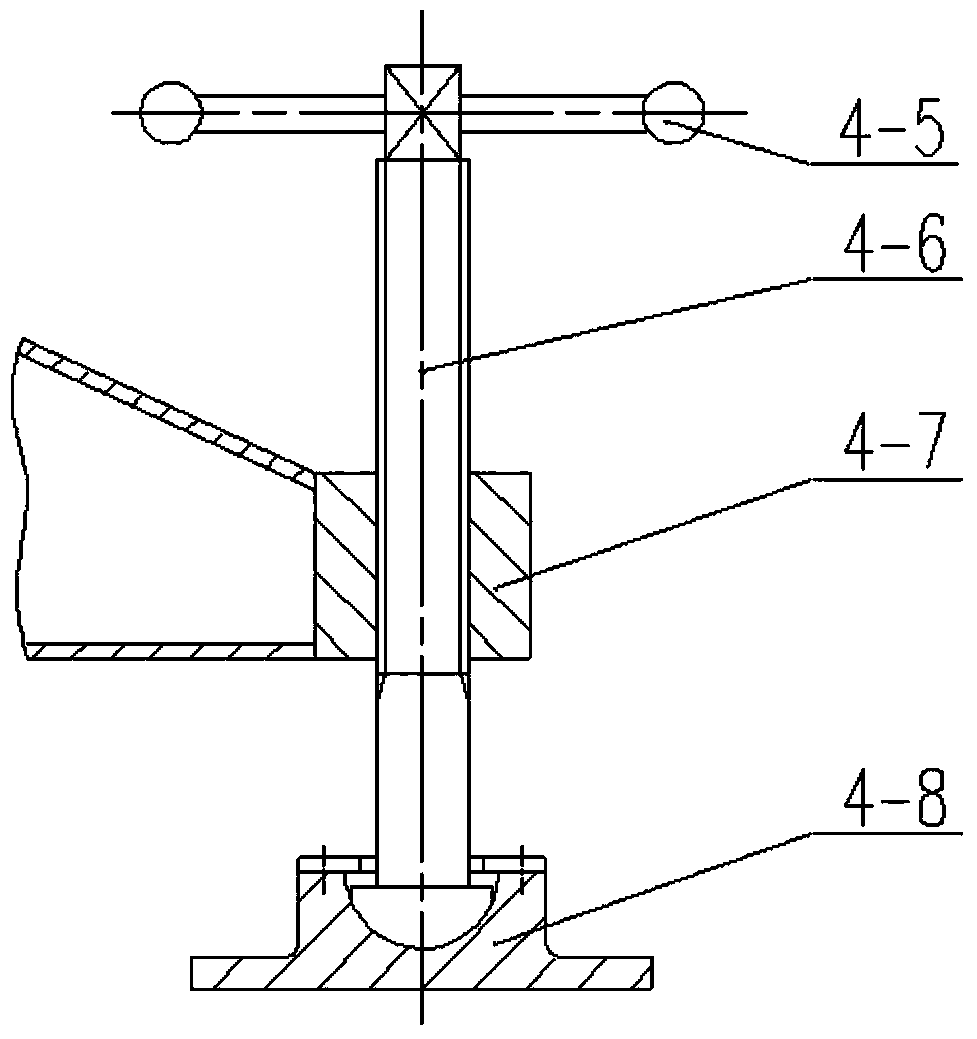

[0025] The bottom end of the vertical column 3 is fixedly connected to the base 4, the bottom of one end of the beam 1 is vertically fixedly connected to the sleeve 1-3, the top of the column 3 is inserted into the sleeve 1-3, and the other end of the beam 1 extends horizontally as a cantilever. There is a convex ring on the column 3, and the bottom end of the sleeve pipe 1-3 is stuck on the convex ring, and the sleeve pipe 1-3 and the column 3 are dynamic fits. A bull gear 3-1 is fixed on the column 3 below the convex ring. The beam 1 is extended to the tail outside the column 3 to fix the motor 1-4, the output shaft of the motor 1-4 is connected to the reducer, and the drive gear 1-5 is fixed on the output shaft of the reducer, and the drive gear 1-5 meshes with the large gear 3-1 .

[0026] The electric h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com