Hydraulic machine

A hydraulic machine and frame technology, applied in the field of hydraulic machines, can solve problems such as poor heat dissipation, oil burning, and unfavorable oil tanks, etc., and achieve good heat dissipation, prolong life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

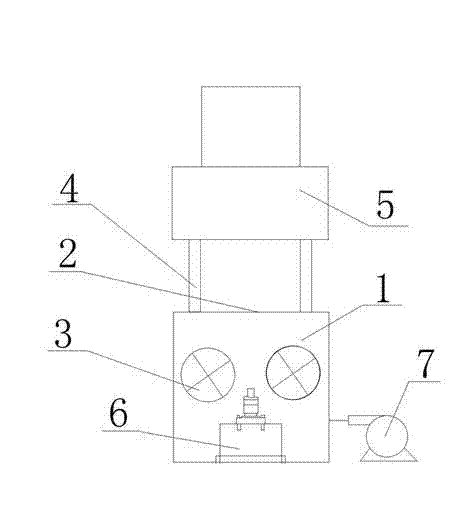

[0016] Such as figure 1 As shown, a hydraulic machine includes a frame 1, a workbench 2 is arranged on the frame 1, a column 4 is arranged along the vertical direction of the workbench 2, the other end of the column 4 is connected to a beam 5, and an oil tank is arranged inside the frame 1 6. A fan 3 is installed inside the rack 1, and a motor 7 is installed on one side of the lower part of the rack 1. The motor 7 provides energy for the fan 3 and controls whether the fan 3 works or not. Both sides of the frame 1 are respectively provided with an air inlet and an air outlet, and the air inlet and the air outlet are arranged opposite to each other. Two fans 3 are installed. Both the air inlet and the air outlet are equipped with steel wire mesh, so that the air will be filtered before entering the inside of the rack 1 to remove large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com