Four-shaft mechanical arm for grabbing sheet metal parts

A technology for four-axis manipulators and sheet metal parts, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of large mechanism size, unsuitable for narrow space operations, etc., and achieve the effect of large working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

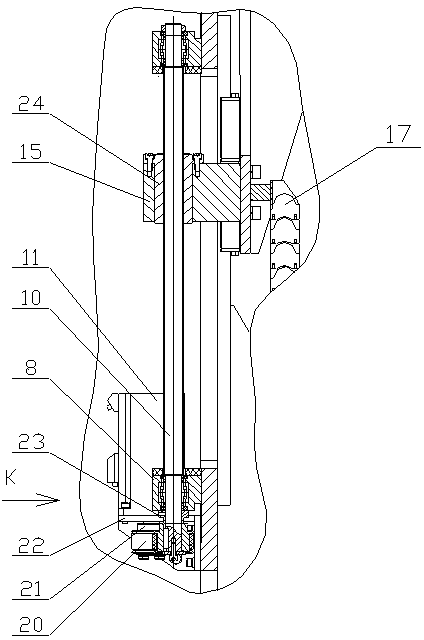

[0033] Such as Figure 1~Figure 9 As shown, a four-axis manipulator for grabbing sheet metal parts involved in this embodiment includes: a one-axis part 1, a two-axis part 2, a three-axis part 3, a four-axis part 4 and an electric control cabinet 5;

[0034] The one-axis component 1 includes a base 7, a screw support seat 8, a ball screw 10, a first AC servo motor 11, a linear guide rail 12, a moving bracket 14, a nut bracket 15, a bridge drag chain 17, a hoof 18, a first Synchronous toothed belt 20, first synchronous belt pulley 21, motor bracket 22, locking ring 23, ball nut 24 and second synchronous belt pulley 26, desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com