Jack shear pin removal device and method

A technology of shearing pins and jacks, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of loose and broken wire ropes, labor and time-consuming, etc., to reduce manpower, simple and easy to implement dismantling methods, and shorten the replacement and maintenance period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

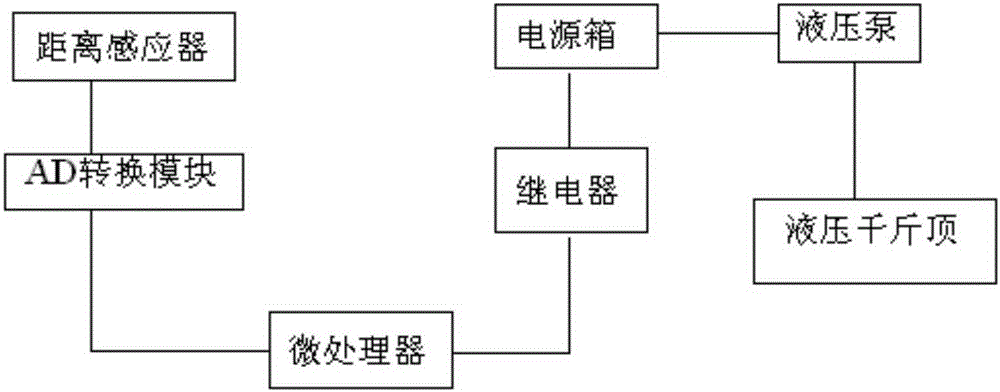

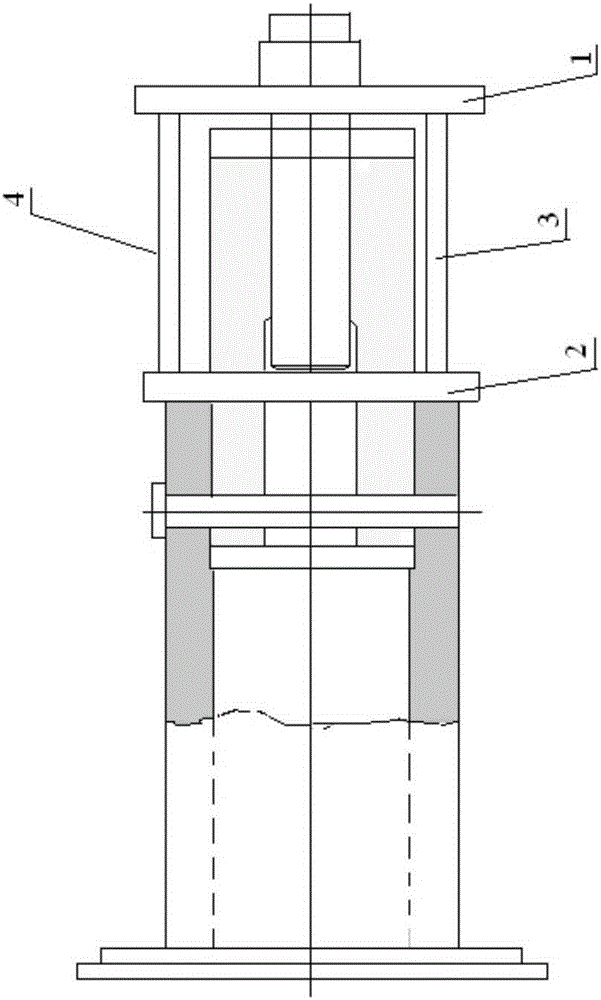

[0024] see figure 1 and figure 2 , the jack shearing pin removal device of the present invention comprises an upper flange 1 and a lower flange 2, a hydraulic jack is arranged between the upper flange 1 and the lower flange 2, and a distance sensor is arranged on the upper flange 1 The distance sensor adopts an infrared distance sensor; the distance sensor is connected with the input terminal of the microprocessor through an AD conversion module, and the output terminal of the microprocessor is connected with the control terminal of the hydraulic jack through a relay. Among them, the microprocessor adopts single-chip microcomputer or DSP.

[0025] Preferably, the hydraulic jack is a thin hydraulic jack, and a first thin hydraulic jack 3 and a second thin hydraulic jack 4 controlled by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com