Auxiliary pressurizing device for sleeve assembling

A technology of assembly aid and pressure device, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as uneven force application, hidden dangers, inconvenient pressure, etc., to ensure product quality, improve work efficiency, Easy product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

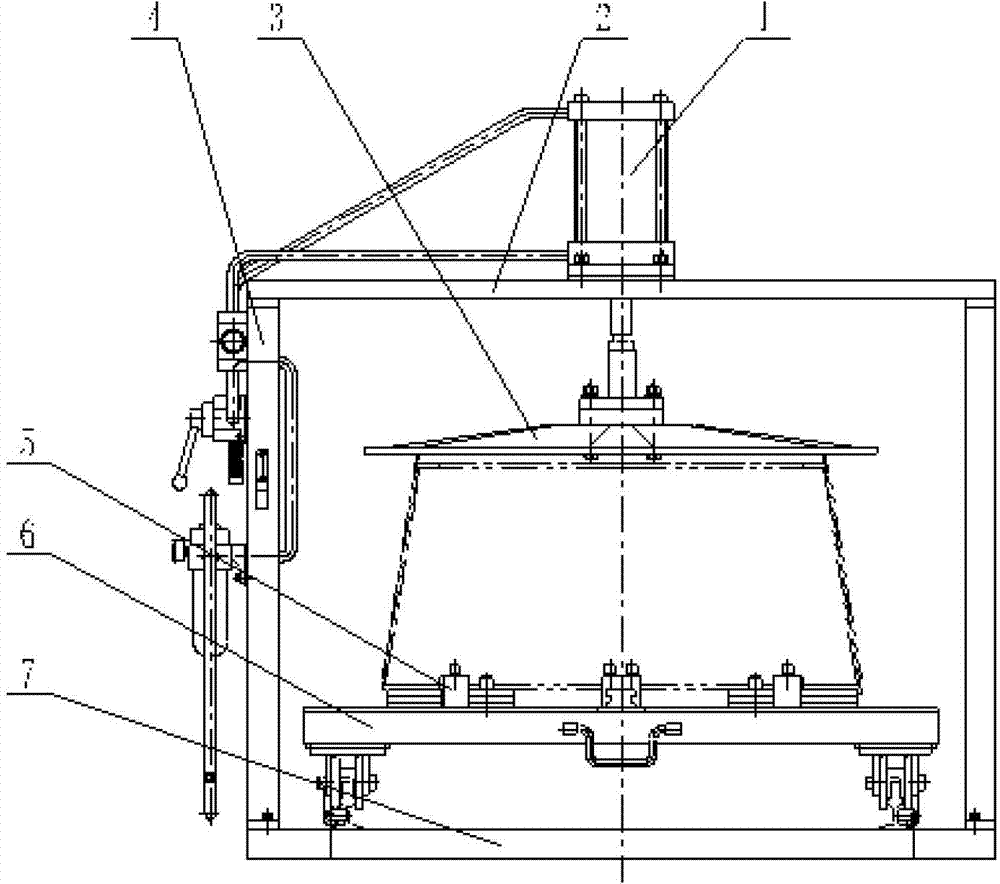

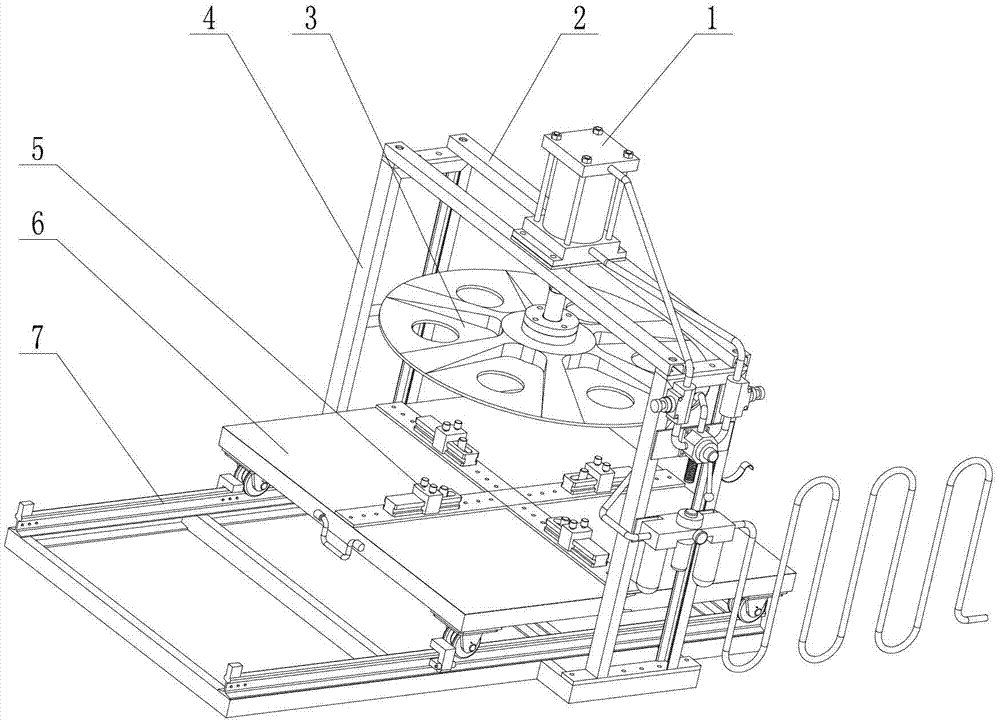

[0026] Such as Figure 1-2 As shown, a suit assembly auxiliary pressurizing device includes a base 7, a sliding trolley 6 is provided on the base, a centering mechanism 5 is provided on the sliding trolley, columns 4 are provided on both sides of the base, and a beam 2 is provided on the top of the column. A pneumatic mechanism 1 is arranged on the beam, and a pressure plate assembly 3 is arranged under the pneumatic mechanism under the beam.

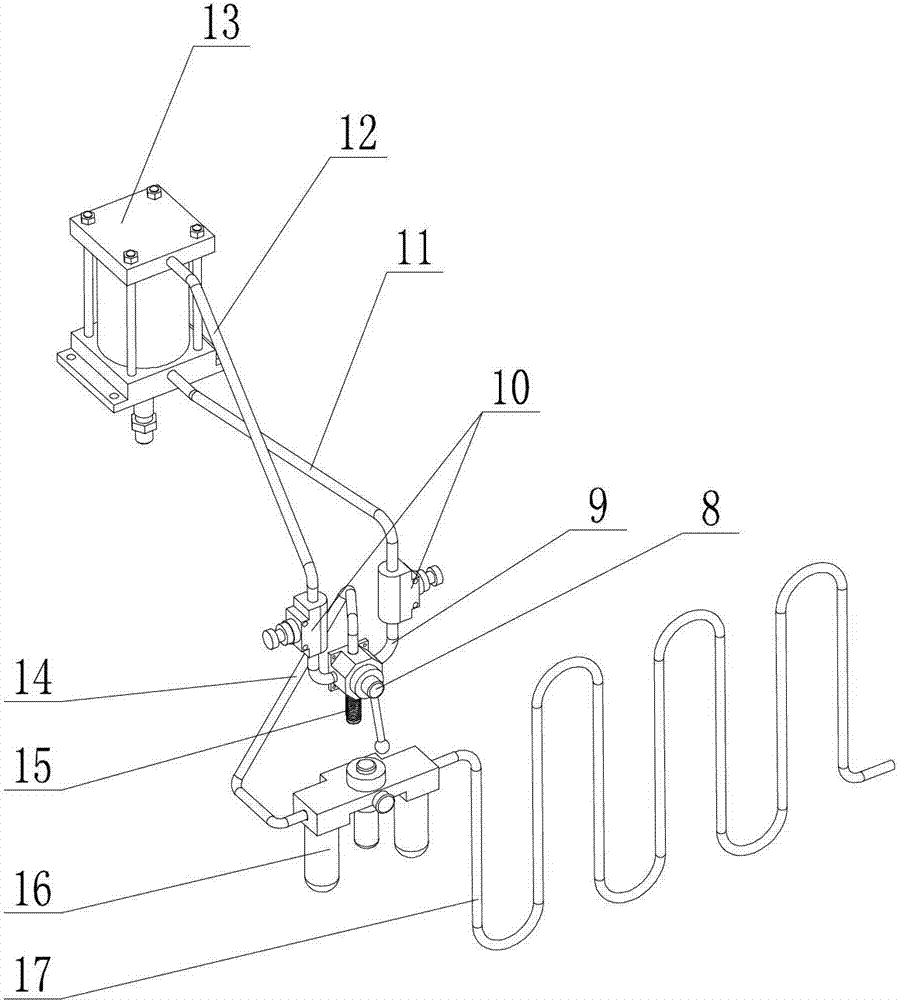

[0027] Such as Figure 3-7 , preferably, the pneumatic mechanism includes a cylinder 13, the upper and lower parts of the cylinder are respectively connected to the cylinder rear end connection pipeline 12 and the cylinder front end connection pipeline 11, the cylinder front end connection pipeline and the cylinder rear end connection pipeline ends are both There is a one-way throttle valve 10, and the two one-way throttle valves are connected to the manual rotary valve 8 through the throttle valve connecting pipeline 9, and the manual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com