Modified electric tapper

A technology of tapping machine and electric motor, which is applied in the direction of thread trimmer, metal processing equipment, thread trimming device, etc., can solve the problems of inability to meet the needs of users, unfavorable health of operators, and high manufacturing costs, so as to protect physical health and improve Tapping efficiency, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

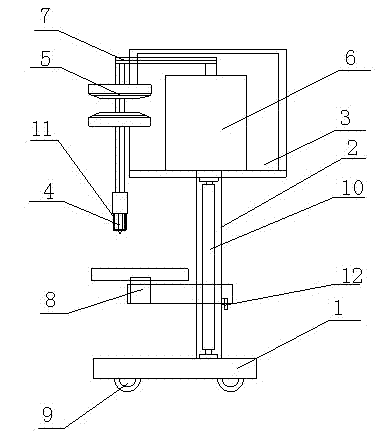

[0014] Such as figure 1 As shown, a kind of improved electric tapping machine of the present invention comprises base 1, the column 2 that is installed on the base 1, the stand 3 that is installed on the top of column 2 and tapping mechanism, and tapping mechanism comprises tapping rod 4, The drive mechanism 5 and the motor 6, the motor 6 is installed on the stand 3, the drive mechanism 5 and the motor 6 are connected by a transmission chain 7, the column 2 is equipped with a workbench 8, the bottom of the base 1 is provided with a moving roller 9, the column 2 is embedded with an illuminating device 10, which is a light emitting diode. The outside of tapping rod 4 is provided with dust collection cover 11, and dust collection cover 11 is elastic retractable type dust collection cover, and workbench 8 is movably installed on the column 2 by movable part 12, and movable part 12 is a latch.

[0015] An improved electric tapping machine of the present invention is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com