Coating method and device for size coating of microporous honeycomb ceramic carrier with openings at two ends

A honeycomb ceramic carrier and microporous technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of difficult control of coating amount, quantitative, uniform load, and difficult cost control, etc., to achieve Improve the quality and purification effect of the catalyst, improve the performance of the automobile catalyst, and realize the effect of sub-area coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Example: The coating slurry formula is: water: 100Kg; Al2O3: 80Kg; binder: 2Kg; additive 1: 5Kg; additive 2: 10Kg; active component: 1.5Kg.

[0038] The specifications of the honeycomb ceramic carrier used in this example:

[0039] Φ101.6X123.3, 400 holes;

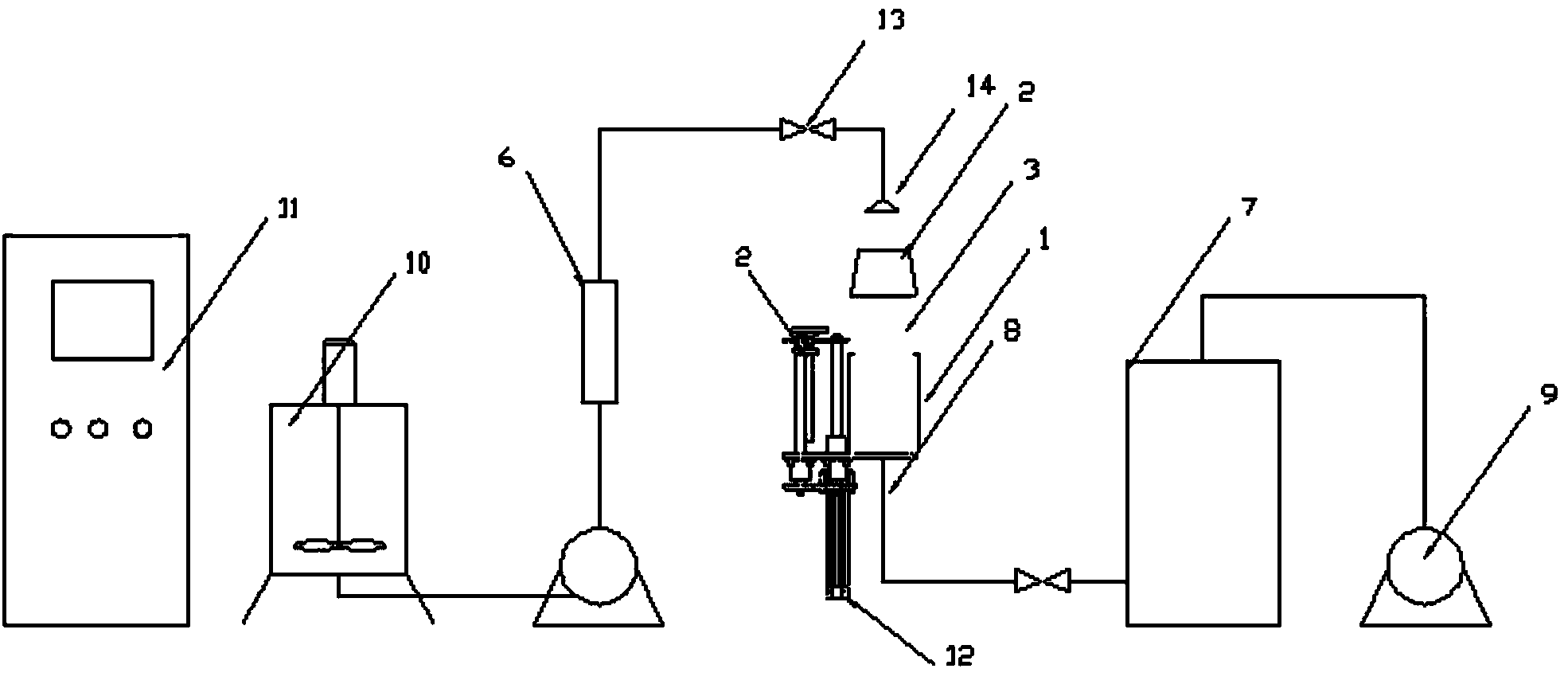

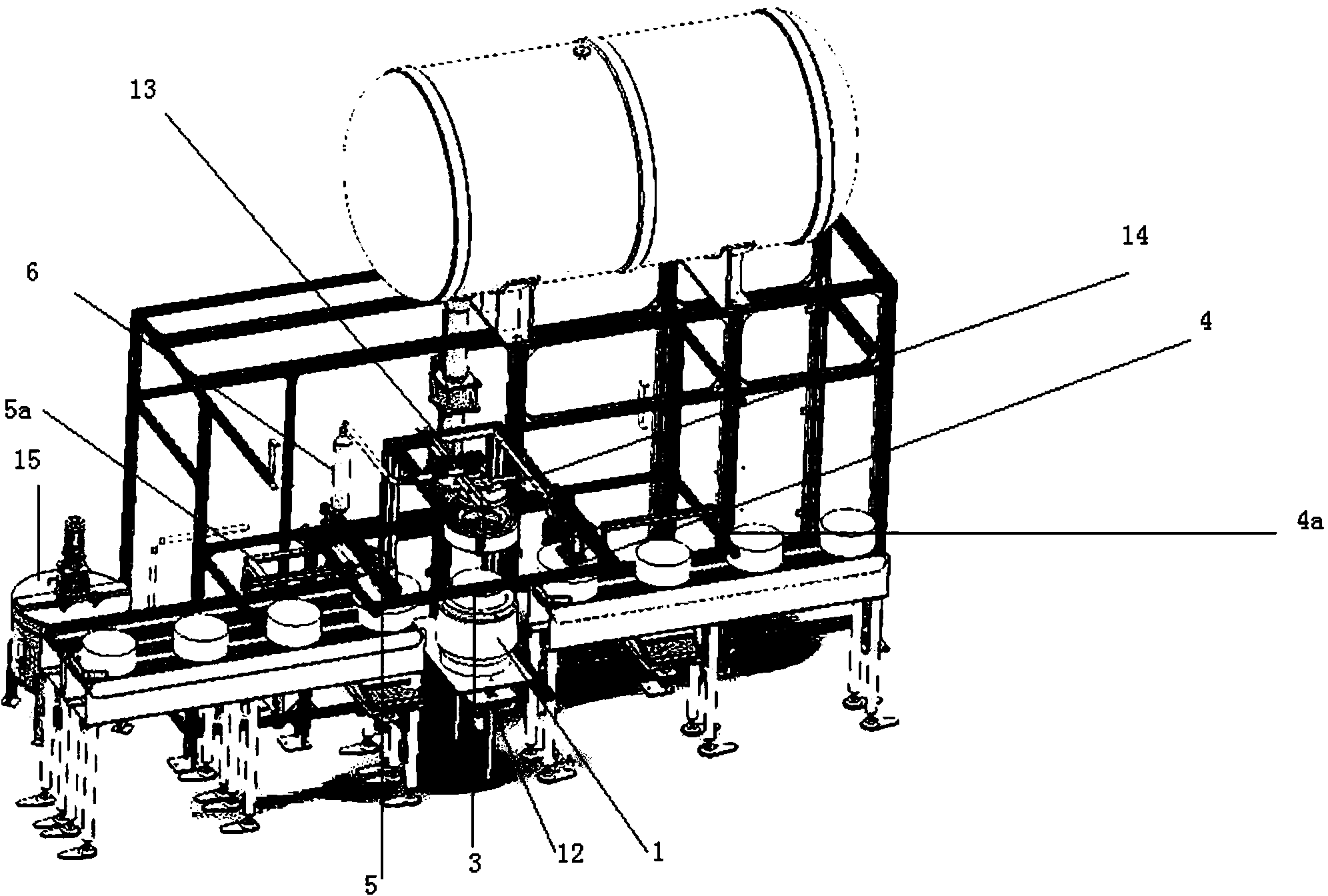

[0040] The basic structure of coating device see figure 1 and figure 2 .

[0041] The connection between the components in the device of the present invention that needs to transmit water and slurry is all pipeline connection, and the connection pipeline can be a stainless steel pipeline, or a pipeline made of organic polymer material, such as PVC and the like. The pipe diameter can be determined according to the size of the device.

[0042] The core device of the present invention is figure 1 The middle and lower tooling 1 and the upper tooling 2, the lower tooling 1 is open at one end and closed at the other end, and both ends of the upper tooling are open, hollow in the middle, and in the shape of a cone ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com