A method of making an optical fiber cladding power stripper

An optical fiber cladding and stripper technology, applied in cladding fibers, multi-layer core/cladding fibers, etc., can solve problems such as damage to the fiber, threatening the safe operation of the laser, and rise, so as to reduce the temperature rise pressure and ensure safety. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples.

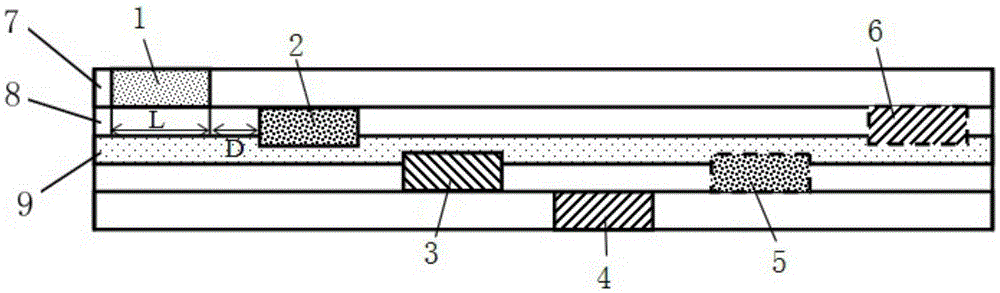

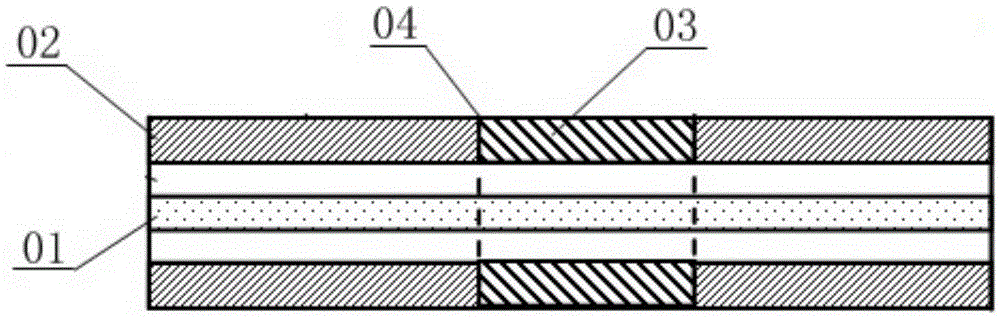

[0022] The method for making the optical fiber cladding power stripper described in this embodiment is to first divide the double-clad optical fiber that needs to be made into a power stripper according to its length direction to have multiple regions; secondly, in the corresponding region, double-clad The low-refractive coating layer on the first-layer optical fiber, that is, the outer cladding, is partially peeled off to obtain the required optical power leakage window nude, and there is a relative rotation angle with the fiber core as the axis between the adjacent optical power leakage window nudes; Finally, the finished bare optical power leakage window is coated and cured with high-refractive index ultraviolet glue, and the power stripper is completed so far. Combine below figure 1 and figure 2 , the inventive method is specified, and its specific circumstances are as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com