Experimental method and device for measuring high-temperature solidification phase transition law

An experimental device and phase transition technology, applied in the direction of measuring device, investigation stage/state change, material analysis through optical means, etc., can solve the problems of small cooling rate, small structure, and inability to simulate the actual working conditions on site, and achieve cooling The effect of constant speed and cooling speed adaptive control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

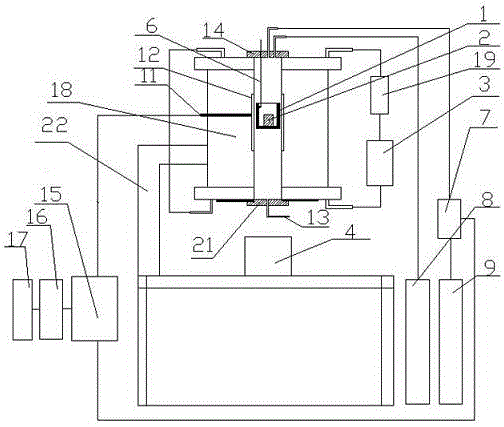

[0043] 1-corundum crucible; 2-sample; 3-circulating water cooling system; 4-liquid nitrogen alcohol container; 5-support rod; 6-sample temperature measurement thermocouple; 7-electromagnetic regulating valve; Bottle; 9-cooling gas Ar gas cylinder; 10-lifting system; 11-furnace body thermocouple; 12-platinum rhodium wire heating system; 13-gas outlet; 14-upper sealing furnace cover; 15-control system; 16-protection System; 17-computer; 18-furnace body; 19-water pump; support sleeve-20.

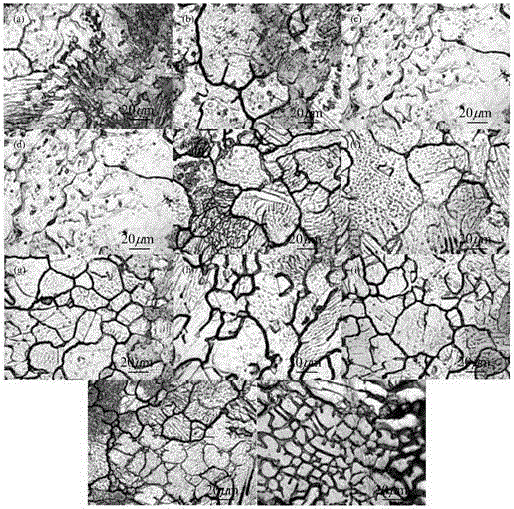

[0044] Figure 4 When material A is cooled to 1479°C, 1475°C, 1460°C, 1450°C, 1440°C, 1430°C, 1420°C, 1410°C, 1400°C, 1390°C and 1380°C at a cooling rate of 0.33°C / s, the liquid Metallographic structure corroded by aqueous regia solution (nitric acid: hydrochloric acid = 1:3 mixed solution) after nitrogen alcohol quenching. Corresponding to a-k in the figure respectively.

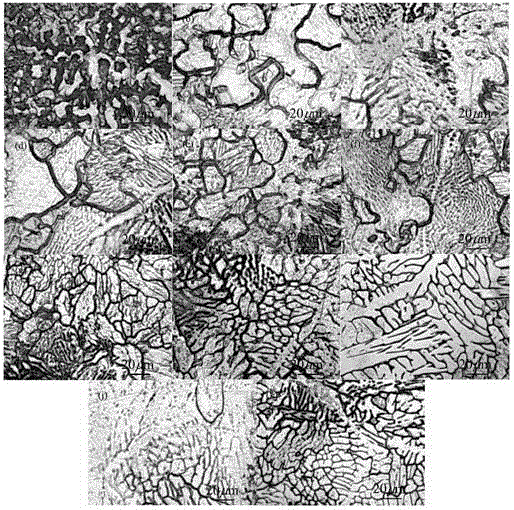

[0045] Figure 5 When material A is cooled to 1500°C, 1450°C, 1440°C, 1430°C, 1400°C, 1380°C, 1375°C, 1370°C, 1365°C, 13...

Embodiment 2

[0056] 1-corundum crucible; 2-sample; 3-circulating water cooling system; 4-liquid nitrogen alcohol container; 6-sample temperature measurement thermocouple; 7-electromagnetic regulating valve; 8-protecting gas Ar cylinder; 9-cooling Ar gas cylinder; 11-furnace body thermocouple; 12-platinum rhodium wire heating system; 13-gas outlet; 14-upper sealing furnace cover; 15-control system; 16-protection system; 17-computer; 18-furnace body ; 19-water pump; Lower sealing furnace cover-21; Support-22.

[0057] Body of furnace 18 top of the present invention is provided with upper stave, and bottom is provided with lower stave, upper stave and lower stave are connected by pipeline, and pipeline and water tank are connected by water pump 19 to form circulating water cooling system 3. The furnace body 18 has a measuring hole for installing the furnace body thermocouple 11, and the inner wall of the furnace body 18 is provided with an insulating layer, and the furnace body 18 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com