Reflecting on-line measuring device and method for textile material spherical compression surface morphology

A technology for textile materials and surface morphology, which is applied in the field of on-line measurement devices for spherical compression surface morphology of reflective textile materials, can solve the problems affecting the structure and compression performance of spacer fabrics, and achieves the effect of exquisite device structure and rapid testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 Measurement of spherical compression surface morphology of textile materials

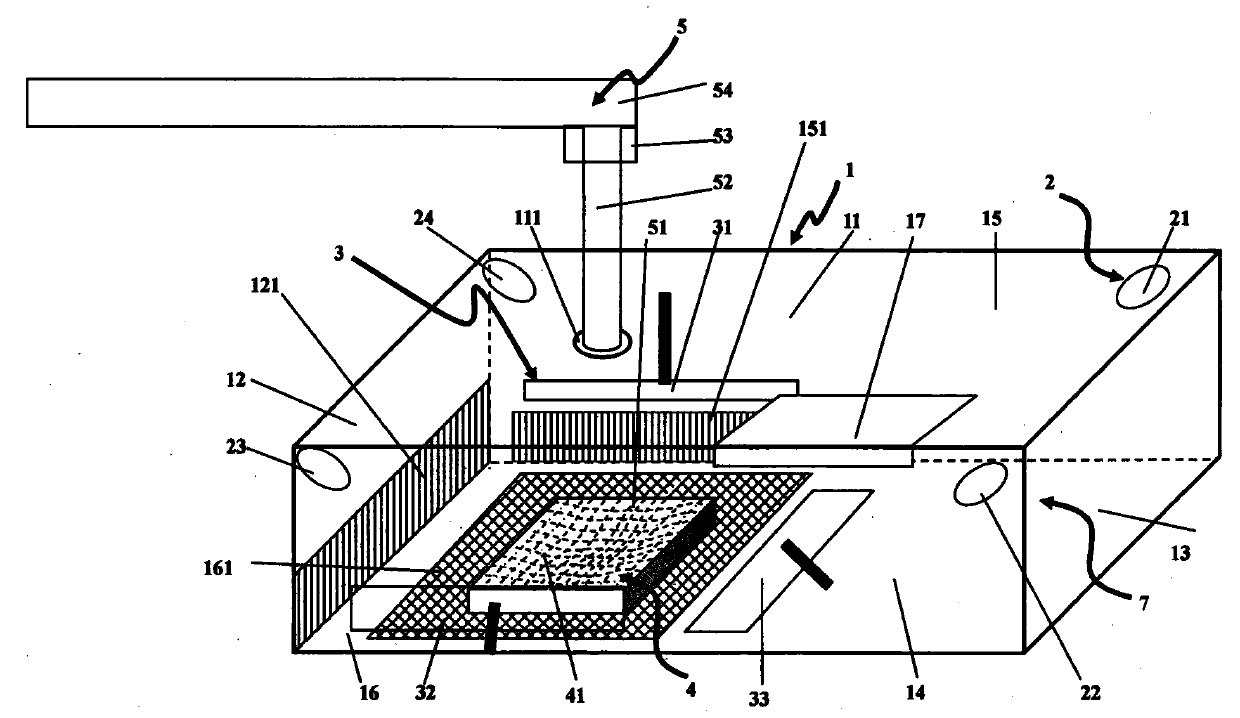

[0051] Such as figure 1 As shown, it is a schematic diagram of an online measurement device for spherically compressed surface morphology of reflective textile materials. The online measurement device for spherically compressed surface morphology of textile materials includes a box 1, such as Figure 12-16 As shown, the box body 1 is composed of a top wall 11, a left side wall 12, a right side wall 13, a front wall 14, a rear wall 15, a bottom wall 16 and an L-shaped door 17, and the L-shaped door 17 is embedded The top wall 11 and the front wall 14 are hingedly connected with the top wall 11; the top wall 11 has a round hole 111, which is coupled with the diameter of the cylindrical fixing rod 53 of the compression mechanism 5, so as to facilitate the fixing rod 53 moves up and down along the vertical direction without friction; the top wall 11, left side wall 12, right side wa...

Embodiment 2

[0057] Example 2 Measurement of Compressed Surface Morphology of Woven Spacer Fabrics

[0058] Such as figure 1 As shown, it is a schematic diagram of an online measurement device for spherically compressed surface morphology of reflective textile materials. The online measurement device for spherically compressed surface morphology of textile materials includes a box 1, such as Figure 12-16 As shown, the box body 1 is composed of a top wall 11, a left side wall 12, a right side wall 13, a front wall 14, a rear wall 15, a bottom wall 16 and an L-shaped door 17, and the L-shaped door 17 is embedded The top wall 11 and the front wall 14 are hingedly connected with the top wall 11; the top wall 11 has a round hole 111, which is coupled with the diameter of the cylindrical fixing rod 53 of the compression mechanism 5, so as to facilitate the fixing rod 53 moves up and down along the vertical direction without friction; the top wall 11, left side wall 12, right side wall 13, fron...

Embodiment 3

[0064] Example 3 Measurement of Compressed Surface Morphology of Knitted Spacer Fabrics

[0065] like figure 1 As shown, it is a schematic diagram of an online measurement device for spherically compressed surface morphology of reflective textile materials. The online measurement device for spherically compressed surface morphology of textile materials includes a box 1, such as Figure 12-16 As shown, the box body 1 is composed of a top wall 11, a left side wall 12, a right side wall 13, a front wall 14, a rear wall 15, a bottom wall 16 and an L-shaped door 17, and the L-shaped door 17 is embedded The top wall 11 and the front wall 14 are hingedly connected with the top wall 11; the top wall 11 has a round hole 111, which is coupled with the diameter of the cylindrical fixing rod 53 of the compression mechanism 5, so as to facilitate the fixing rod 53 moves up and down along the vertical direction without friction; the top wall 11, left side wall 12, right side wall 13, front...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com