A PHC pipe pile phase change energy storage system and its construction method

A PHC pipe pile and phase change energy storage technology, which is applied to sheet pile walls, heat storage equipment, infrastructure engineering, etc., to achieve the effects of long energy storage time, improved energy storage, and increased heat storage function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

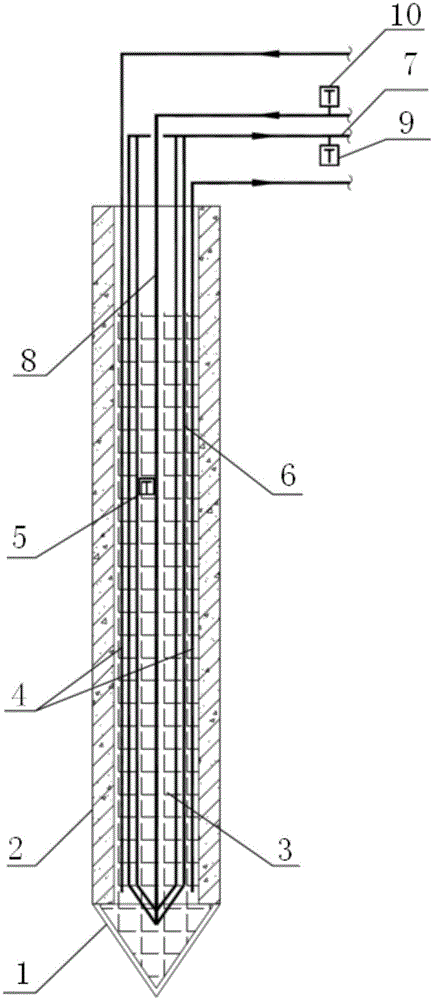

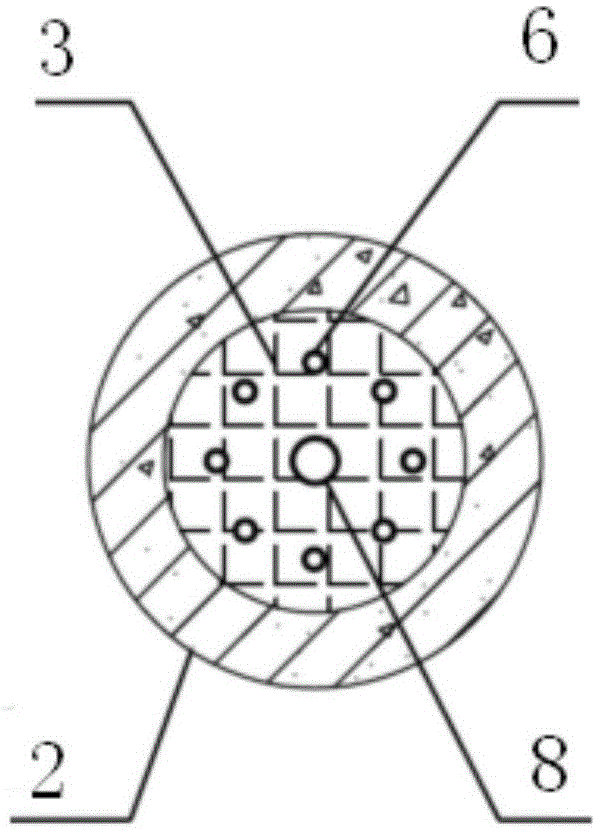

[0031] Such as Figure 1-2 As shown, the PHC pipe pile phase change energy storage system described in the embodiment of the present invention includes a PHC pipe pile 2. In order to prevent soil from entering the cavity in the PHC pipe pile 2, the bottom end of the PHC pipe pile 2 is provided with a pipe pile Point 1, the cavity of the PHC pipe pile 2 is filled with a high-temperature phase change energy storage material 3, and the cavity of the PHC pipe pile 2 is provided with a water supply main pipe 8, a number of vertical return water branch pipes 6 and energy storage materials Maintenance pipe 4, wherein, the water supply main pipe 8 is arranged at the center of the cavity, and the several return water branch pipes 6 are vertically arranged around the water supply main pipe 8 and are bent at the pile tip and converged to communicate with each other for energy storage The material maintenance pipes 4 are arranged on both sides of the cavity, and two energy storage materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com