Bearing and driving mechanism for sliding door of urban rail vehicle

A technology of urban rail and driving mechanism, applied in the direction of power control mechanism, wing fan control mechanism, door/window fittings, etc. Problems such as long movement and force transmission routes, to achieve the effect of improving bearing capacity, facilitating replacement and maintenance, and stabilizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

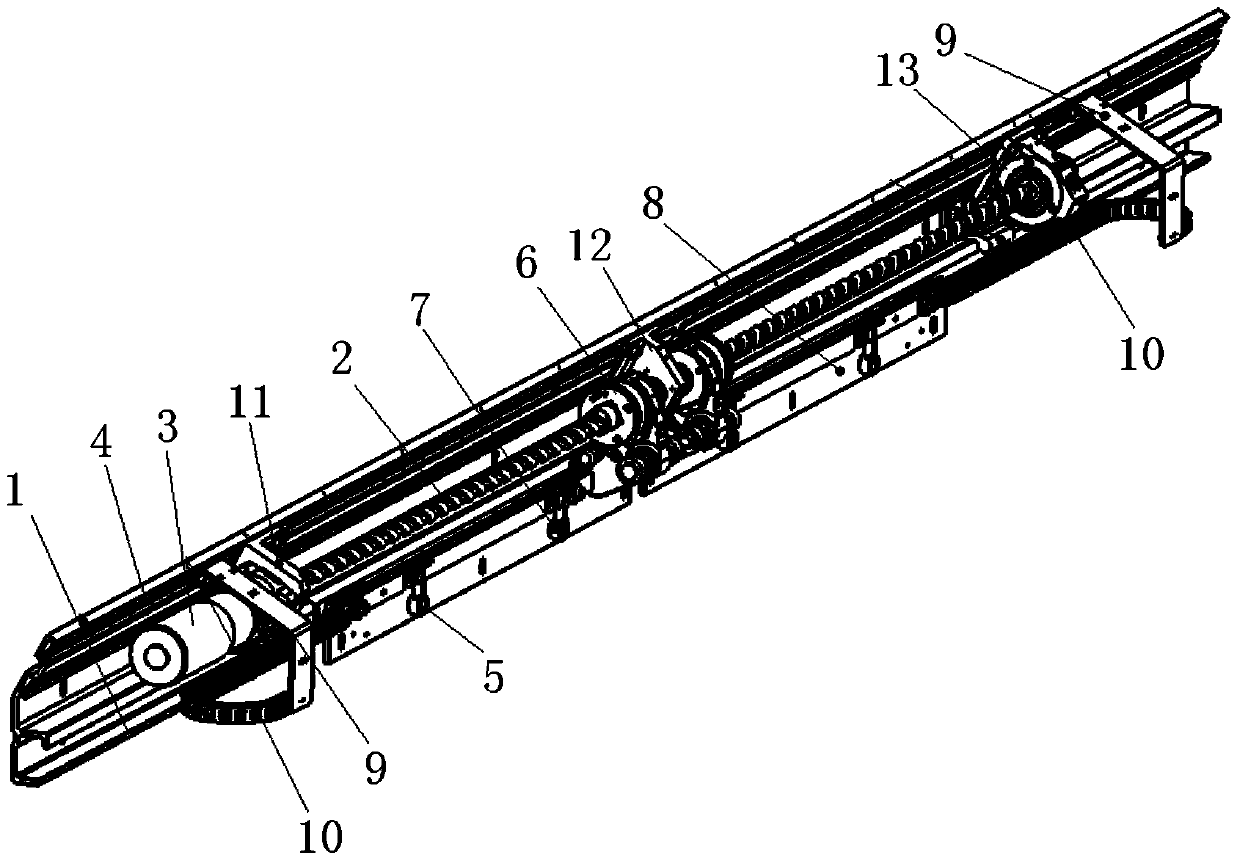

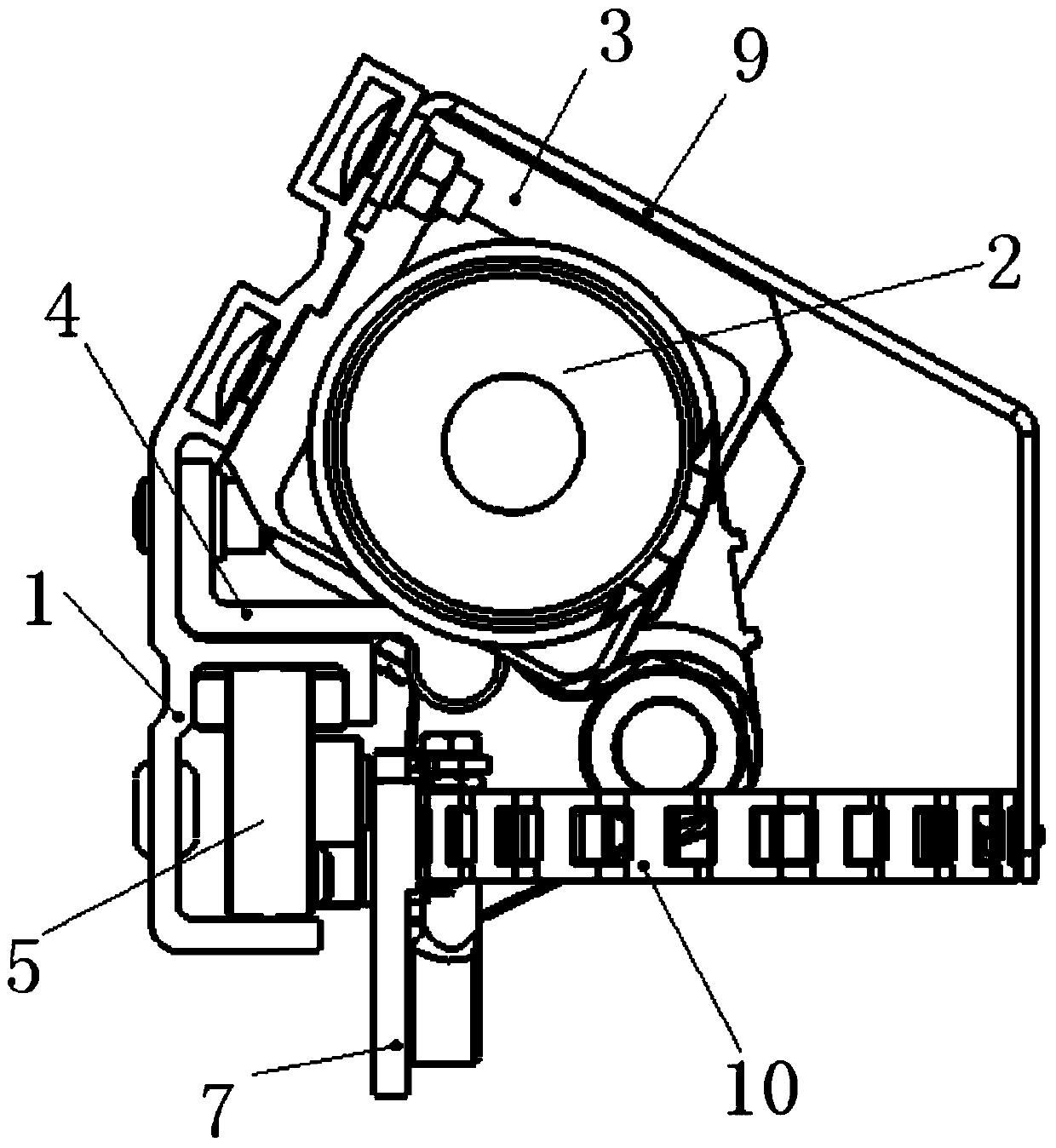

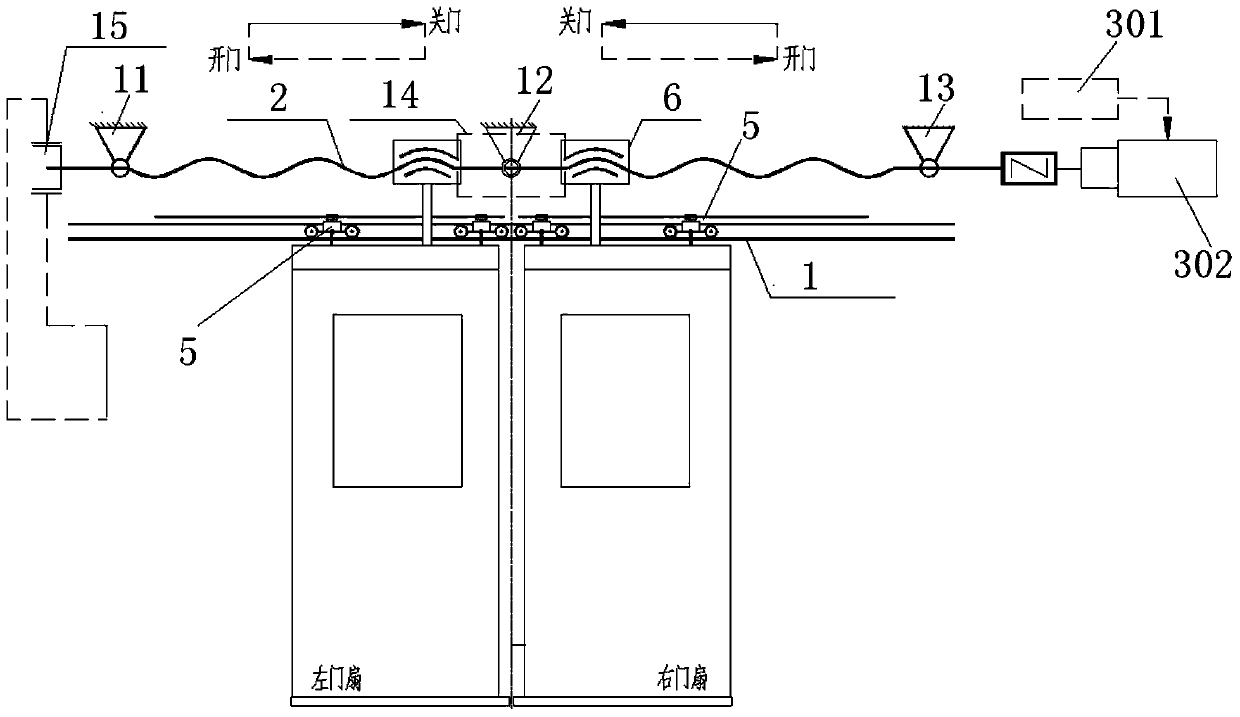

[0034] Such as figure 1 , figure 2 and image 3 As shown, the load-bearing drive mechanism for urban rail vehicle sliding doors of the present invention includes a slideway assembly 1, a drive screw 2, a screw drive assembly 3, a drive bracket 4, a load wheel 5, a left door leaf load bracket 7, a right door leaf carrying bracket 8, drag chain bracket 9 and drag chain 10,

[0035] Described driving screw mandrel 2 is installed in the inside of driving bracket 4, and one side of driving screw mandrel 2 is provided with screw mandrel driving assembly 3, and screw mandrel driving assembly 3 comprises driving motor 301 and sliding door controller 302, and sliding door controller 302 Control the rotation of the drive motor 301 to drive the drive screw 2 to rotate, and the high pair connection mechanism 6 on the drive screw 2 controls the left door leaf bearing bracket 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com